Locking mechanism for electronic lead seal

A locking mechanism and electronic lead sealing technology, applied in the directions of seals, stamps, instruments, etc., can solve the problems of cumbersome operation, unfavorable work efficiency, etc., and achieve the effect of convenient installation and operation and good use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, concrete structure among the present invention is described:

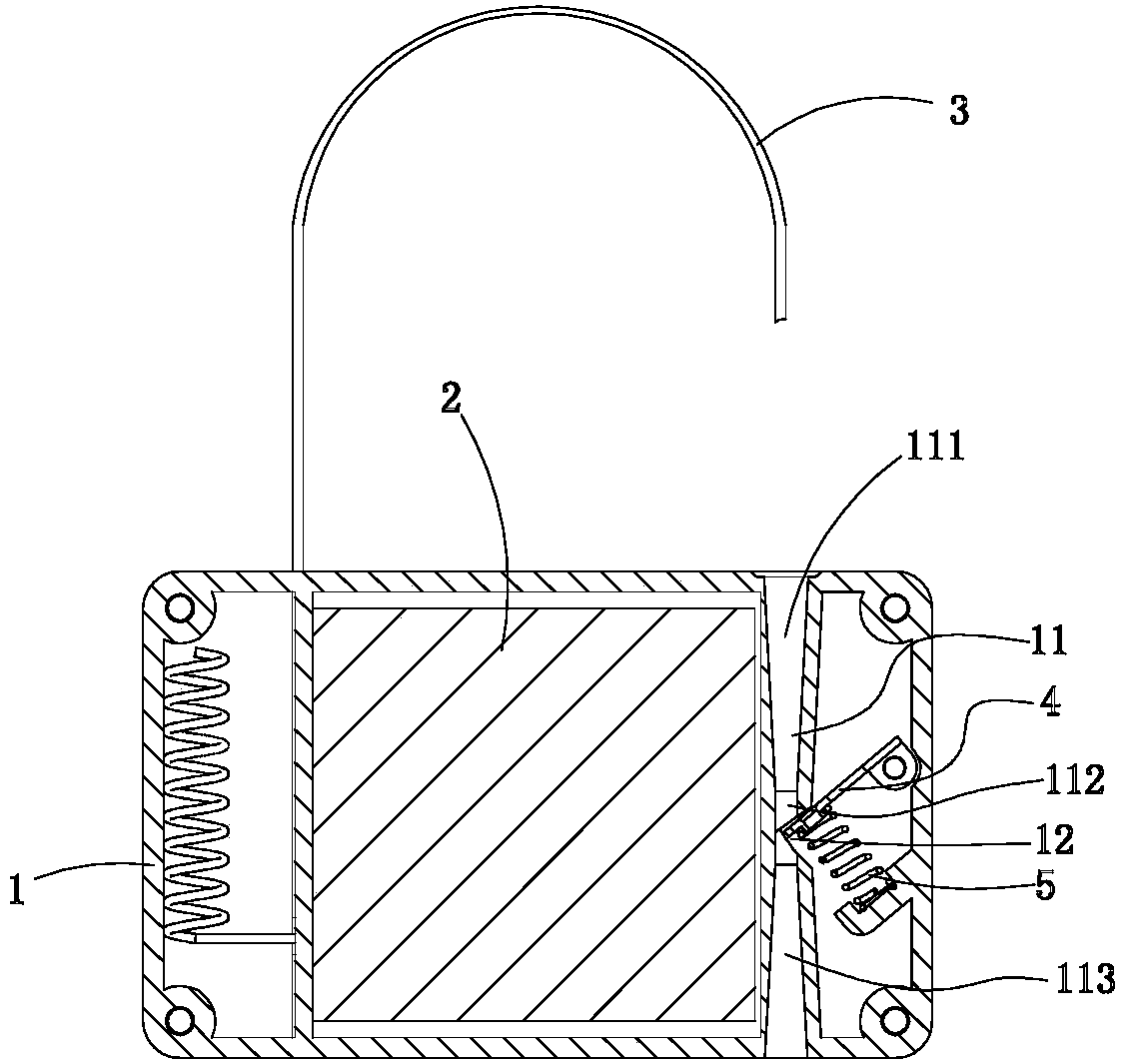

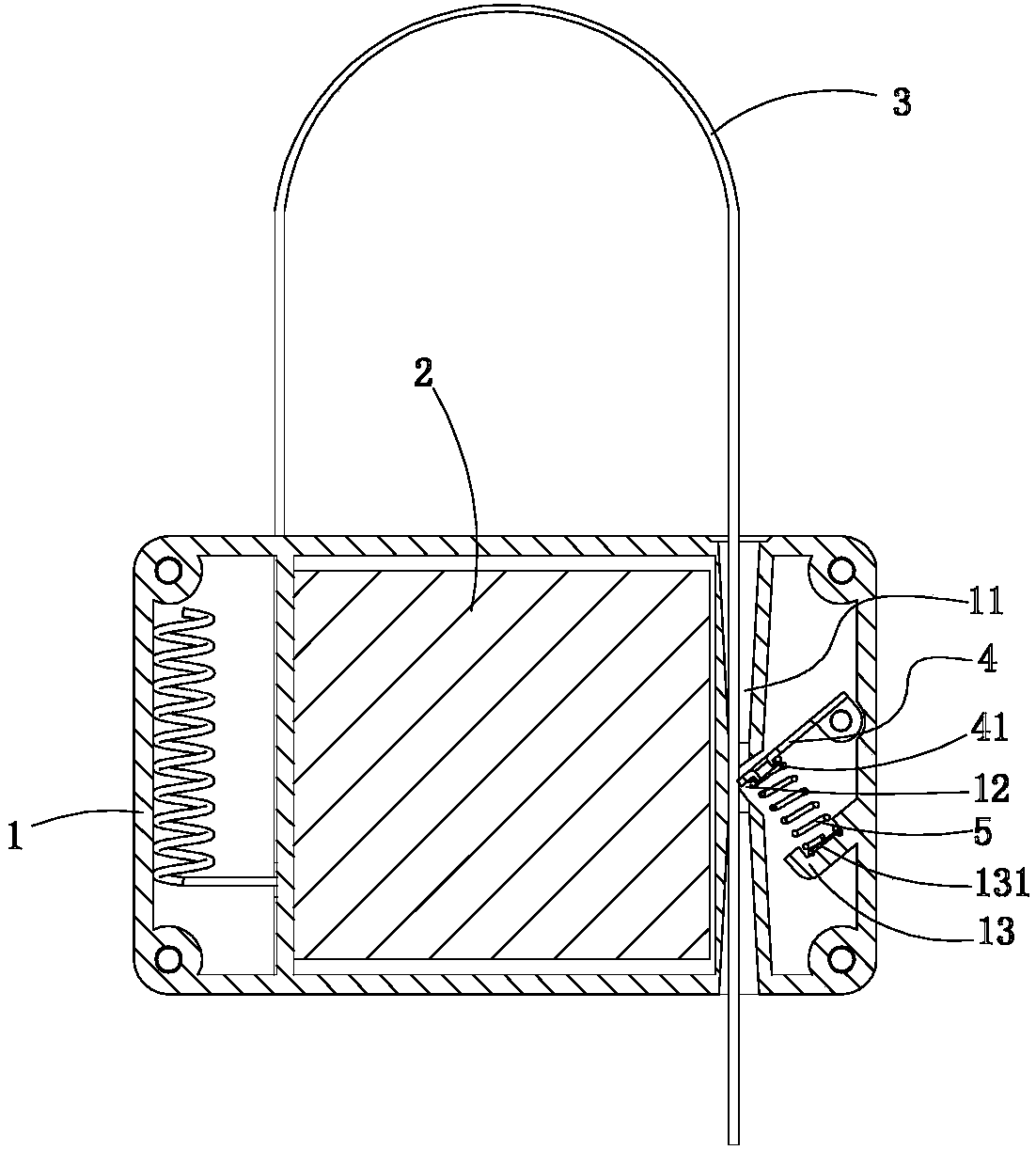

[0017] A locking mechanism for electronic lead seals, such as figure 1 and figure 2 As shown, it includes a housing 1, the housing 1 has a seal hole 11 for the seal wire 3 to pass through, and a locking mechanism is arranged in the housing to lock the seal wire 3 in the In the lead seal hole 11, a gap 12 is provided in the middle of the lead seal hole 11, and the locking mechanism includes a locking piece 4 for pressing the lead sealing line 3 and provides locking elastic force for the locking piece 4 The elastic part 5, the locking piece 4 is rotatably installed inside the housing 1 through the connecting shaft, and under the action of the elastic part 5, the free end of the locking piece 4 extends into the notch 12 Inside the lead-sealed hole 11. When the above-mentioned electronic seal is installed, the free end of the seal wire 3 is inserted into the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com