Punch with automatically regulating balancer

An automatic adjustment and balancer technology, used in manufacturing tools, presses, etc., can solve problems such as seizure, large differences in setting values, and affecting the accuracy of stamping products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

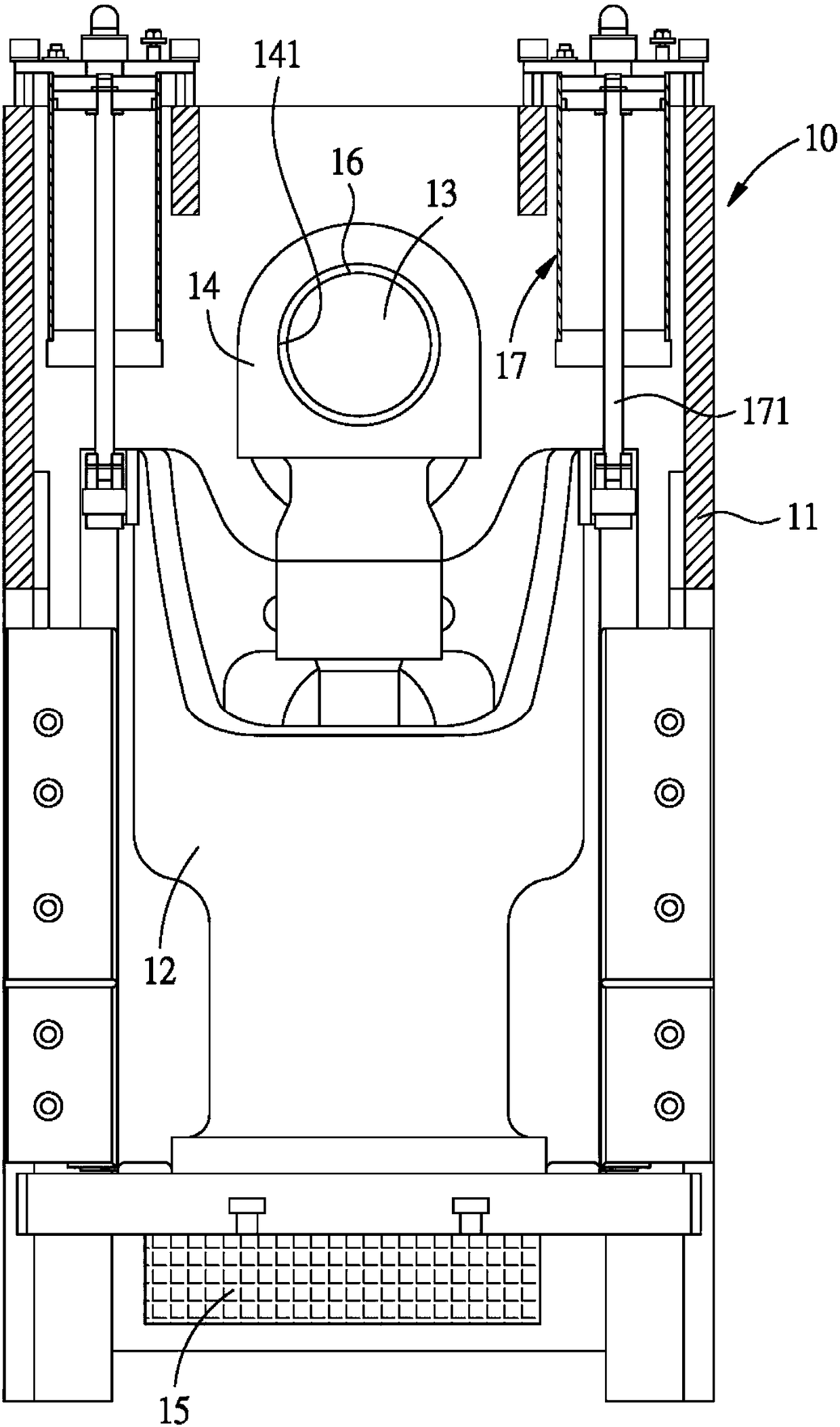

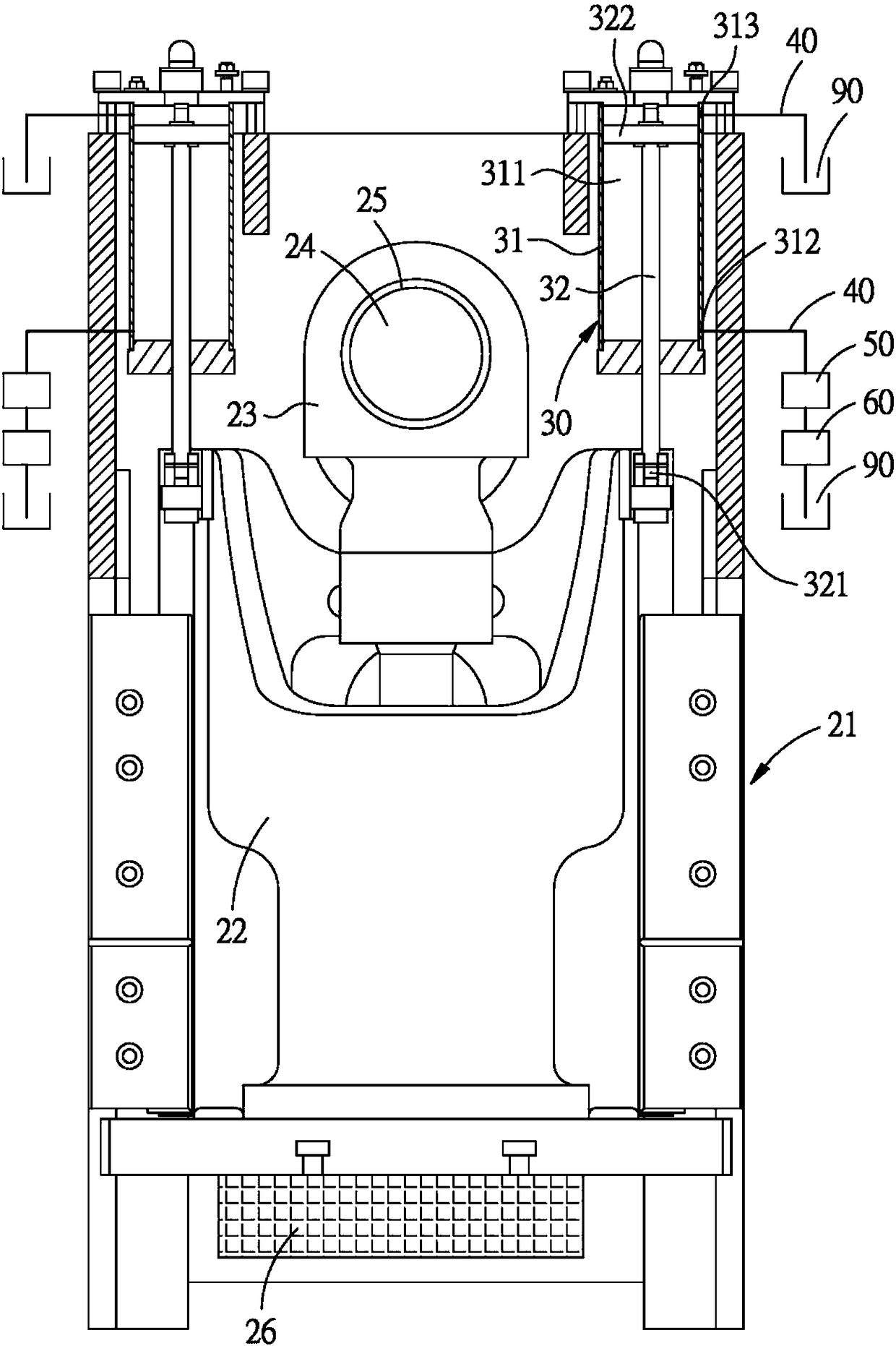

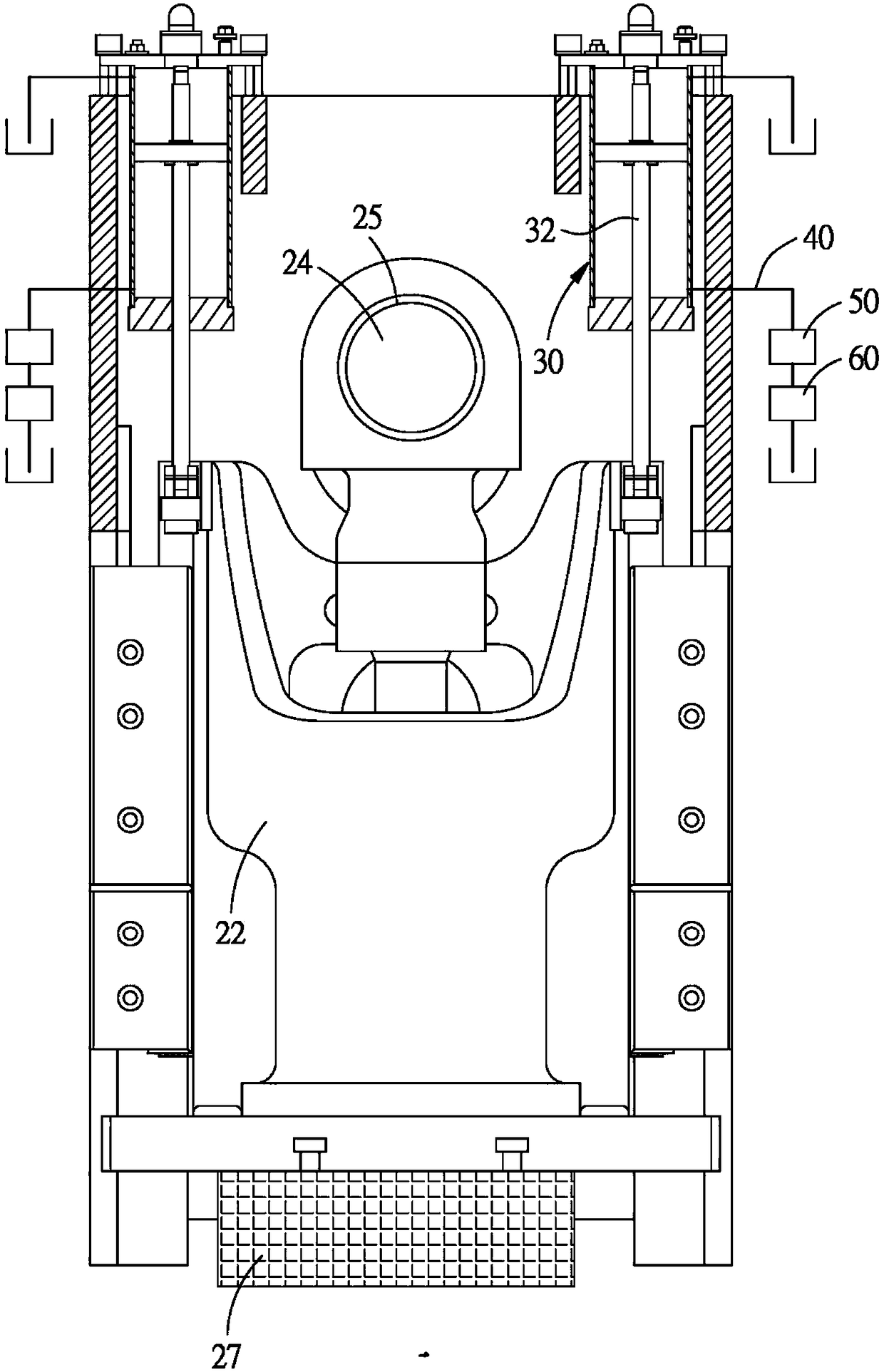

[0039] Please refer to Figure 2 to Figure 4 As shown, the embodiment of the present invention provides a punch press with an automatic balancer, which is mainly composed of a machine base 21, a slider group 22, a connecting rod 23, a crankshaft 24, a copper alloy 25, and a Self-adjusting balancer consisting of:

[0040] The slider set 22 is arranged on the base 21 so as to be able to reciprocate up and down; in this embodiment, a first mold 26 with a first weight is arranged on the lower end surface of the slider set 22 .

[0041] The connecting rod 23 is connected to drive the slider group 22 .

[0042] The crankshaft 24 is rotatably inserted on the connecting rod 23 to drive the connecting rod 23 to move.

[0043] The copper alloy 25 is arranged between the crankshaft 24 and the connecting rod 23 .

[0044] Because the machine base 21, the slider group 22, the connecting rod 23, the crankshaft 24, and the copper alloy 25 are all known components, and their configuration ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap