a shock absorber

A shock absorber, ball screw technology, applied in the direction of shock absorber, shock absorber, shock absorber-spring combination, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

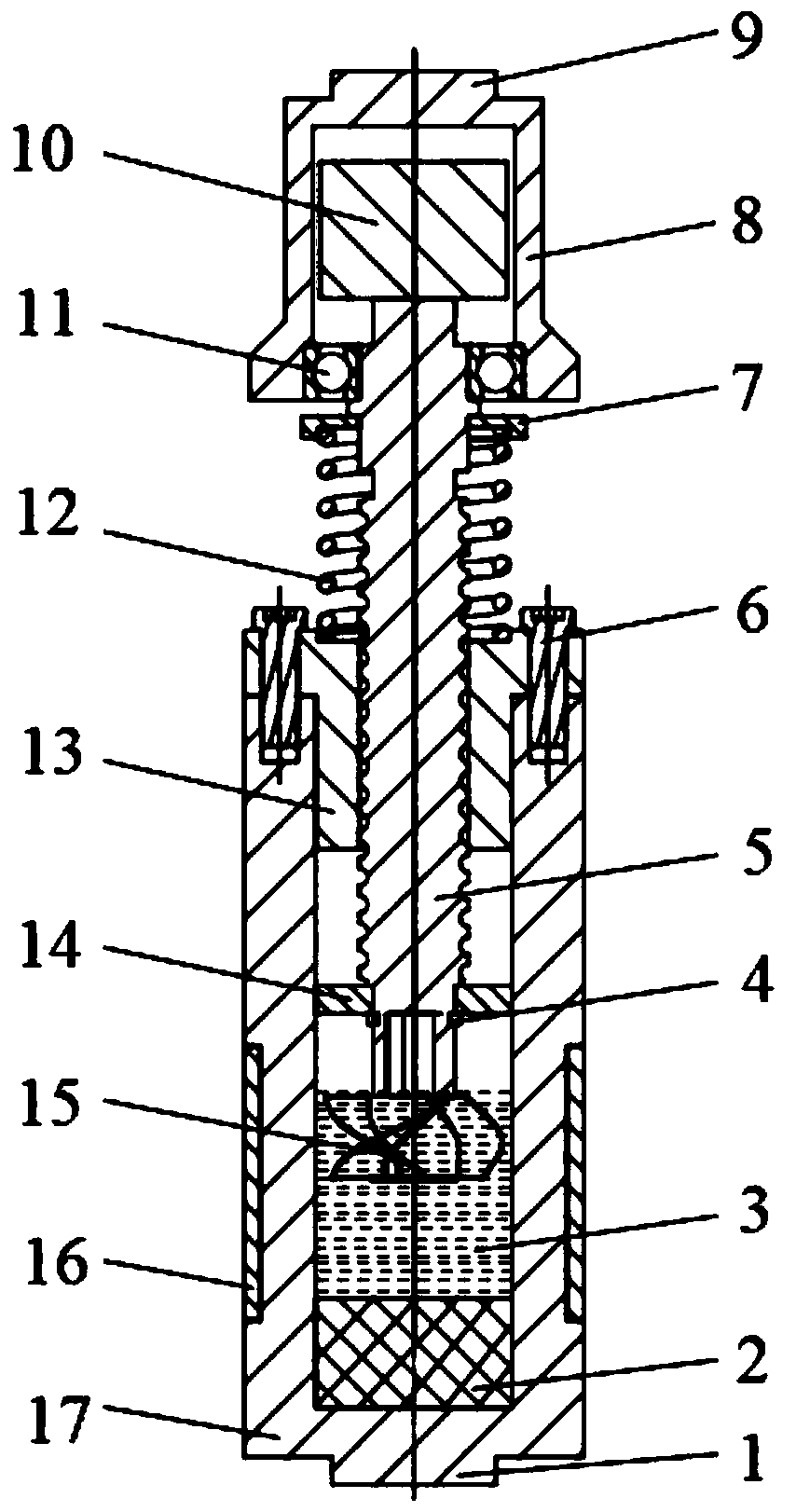

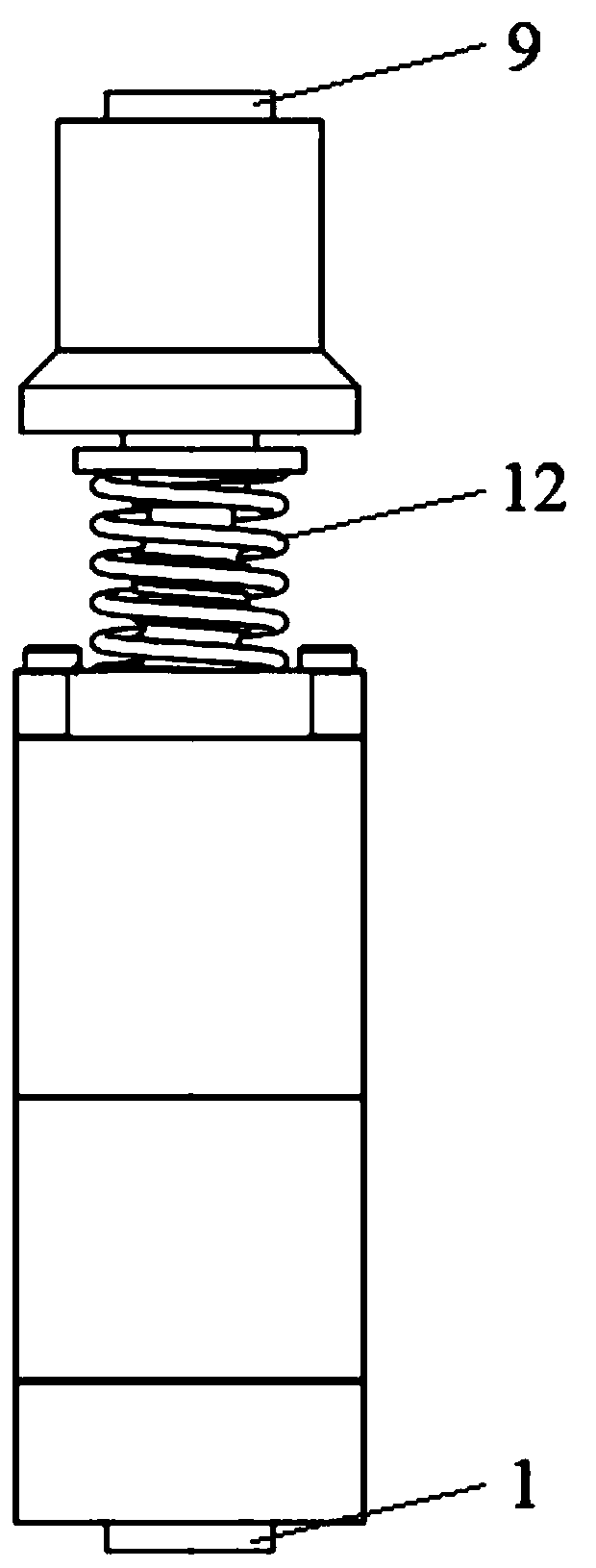

[0027] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0028] It should be noted that the "up and down" mentioned in the present invention only represent the relative orientation relationship, and do not represent the absolute orientation in the earth coordinate system. For example, the "down" direction does not necessarily coincide with the direction of gravity. "Up" refers to the direction of the roller screw towards the flywheel chamber, and "down" refers to the opposite direction.

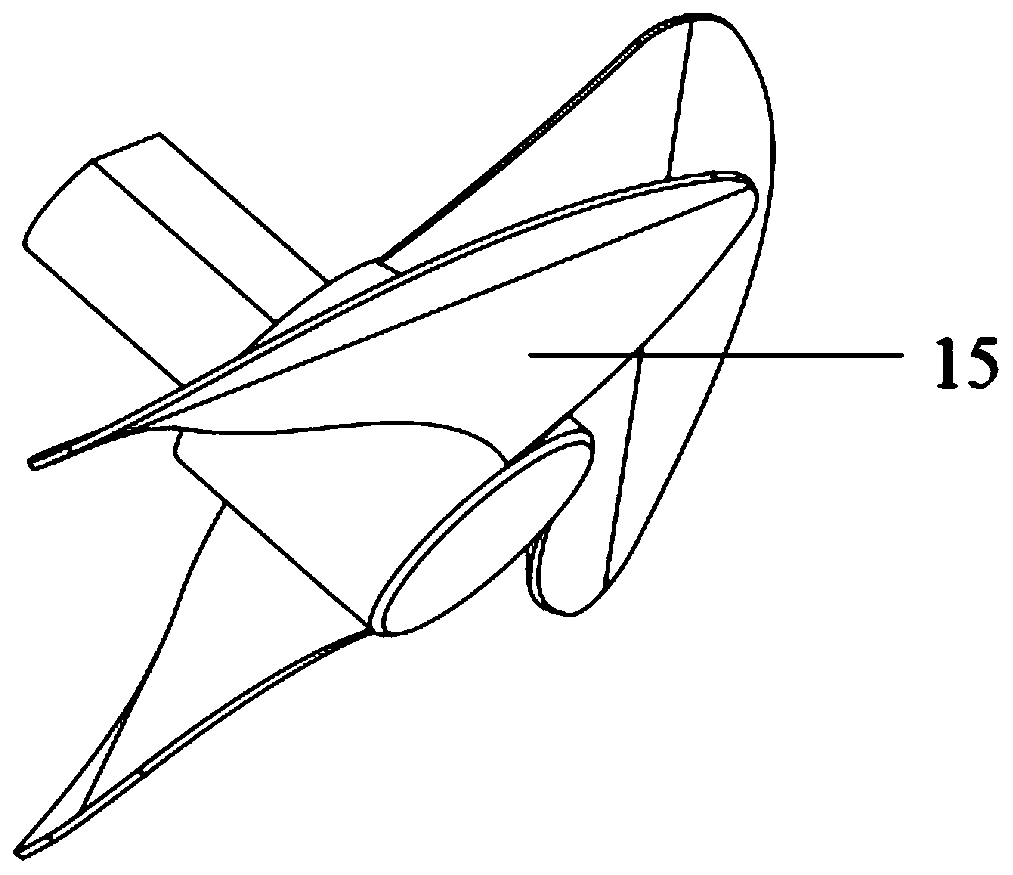

[0029] Such as figure 1 As shown, the ball screw 5 is embedded in the chamber of the flywheel chamber 8 and the stroke chamber 17, and is threadedly connected with the nut 13 to form a kinematic pair, and the nut 13 is installed on the stroke chamber 17 through the fastening screw 6. During the movement, the nut 13 does not move, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com