Primer assembly device and method

A technology of assembling device and assembling method, which is applied in the directions of weapon accessories, fuzes, ammunition, etc., can solve the problems of high assembly risk and explosion, and achieve the effect of enhancing safety, using safety and increasing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

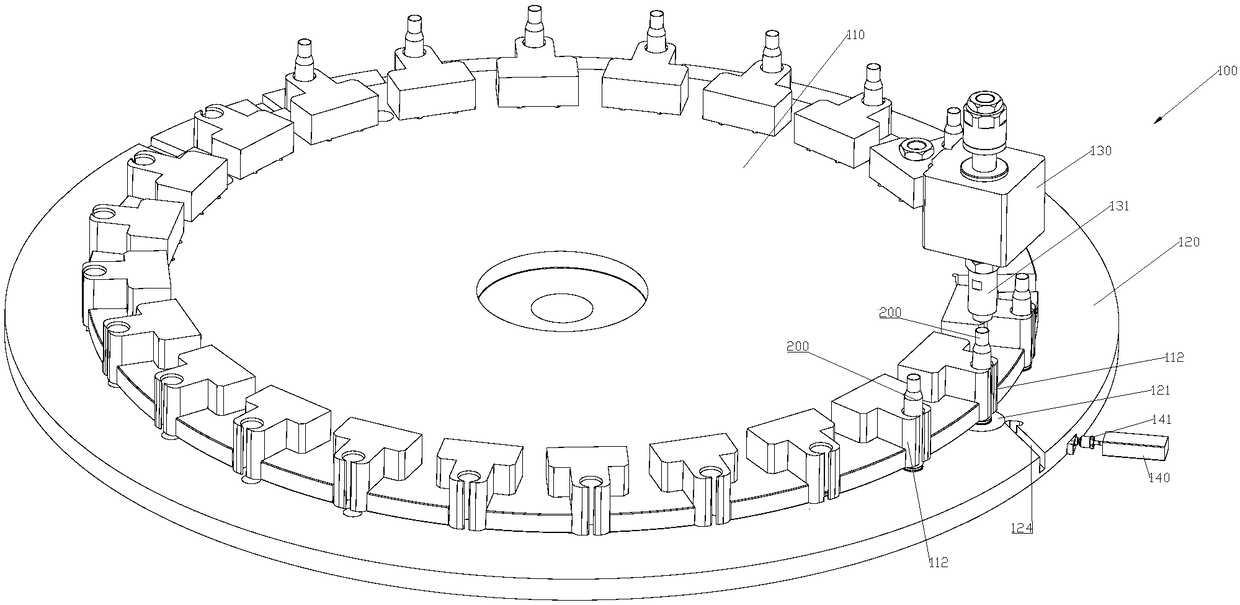

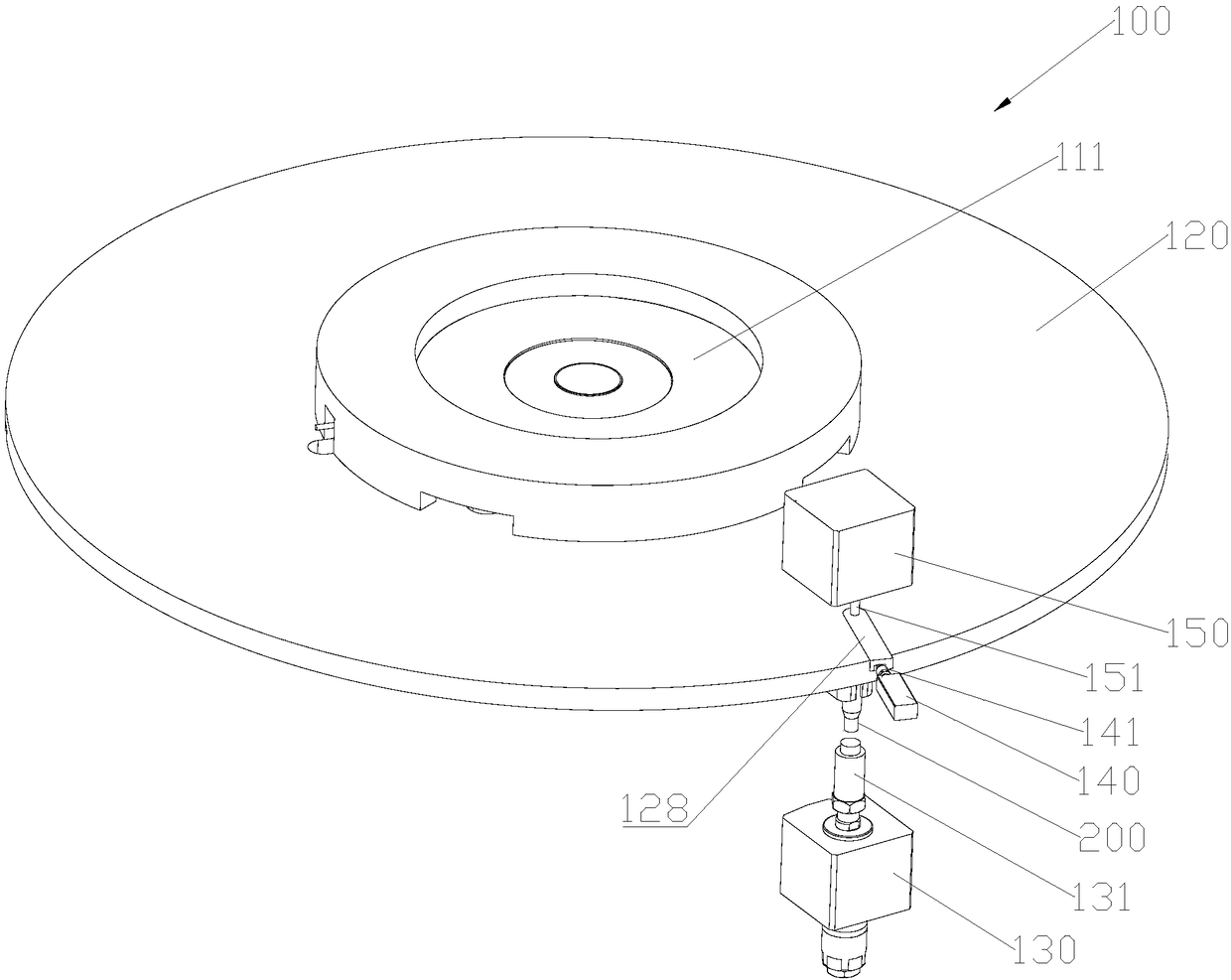

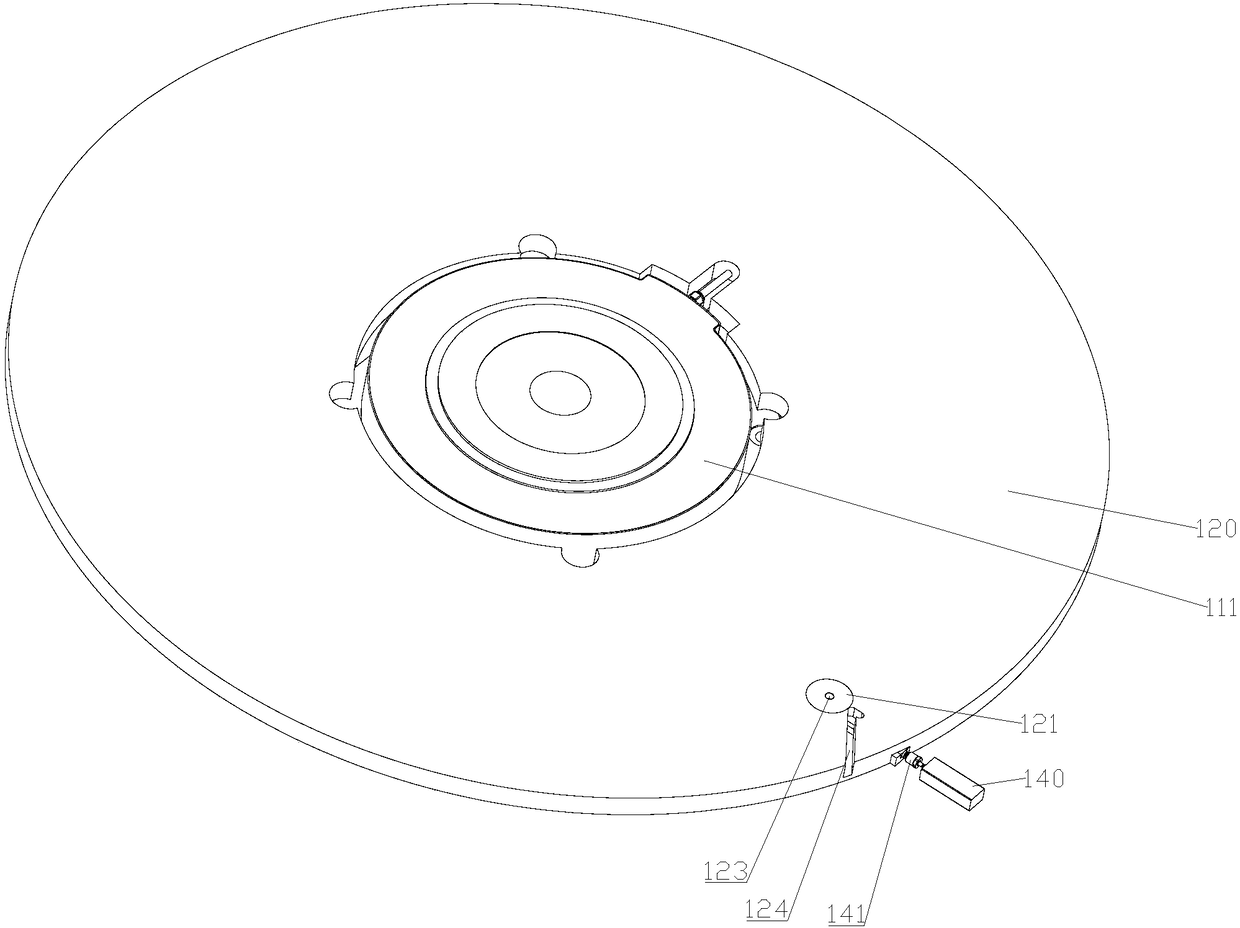

[0038] like figure 1 As shown, the primer assembly device 100 includes a turntable 110 and a base 120 . The turntable 110 is a conveying device for conveying the shell casings 200 . The turntable 110 is circular and rotatably arranged. A drive device 111 is disposed below the turntable 110, and the drive device 111 is used to drive the turntable 110 to rotate. The driving device 111 may adopt a DD motor. A plurality of grippers 112 are arranged on the edge of the turntable 110 , and the plurality of grippers 112 are distributed at intervals along the circumferential direction, and each gripper 112 is used to carry a cartridge case 200 .

[0039] like figure 1 , figure 2 As shown, a base 120 is disposed below the turntable 110 . The turntable 110 is spaced apart from the base 120 . The base 120 is a supporting device for supporting the shell case 200 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com