A Method for Measuring the True Stress of Materials

A technology of real stress and samples, which is applied in the field of material science, can solve the problems of unable to measure and calculate stress, and achieve the effect of strong market promotion value, wide application range and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The following examples are for as-cast Zr 50 Cu 44 al 6 (at.%) round bar shape amorphous alloy sample.

[0056] The measurement cast Zr of present embodiment 50 Cu 44 al 6 (at.%) The method for the true stress of the amorphous alloy comprises the following specific steps:

[0057] (1) Using the dynamic method (acoustic method) to measure the as-cast Zr 50 Cu 44 al 6 Poisson's ratio of amorphous alloy μ=0.37;

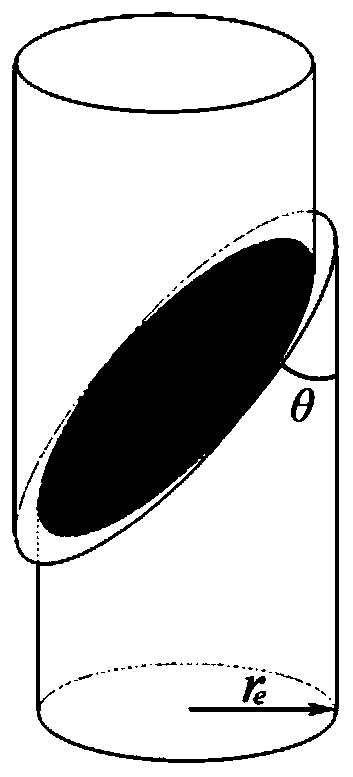

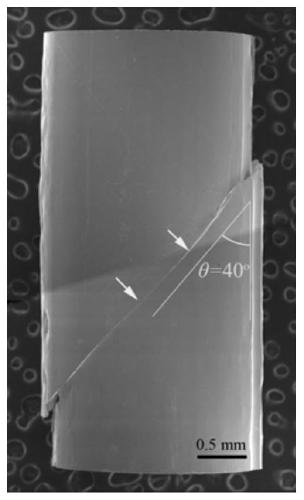

[0058] (2) Zr in the shape of a round rod (circular in cross section) 50 Cu 44 al 6 The original length l of the amorphous alloy 0 The sample is 4.20mm and the radius is 1.09mm. The universal force mechanical testing machine is used to uniaxially compress the sample to obtain the load-displacement curve. Combined with the sample size, the engineering stress-strain curve is obtained, and then the formula (1) and ( 2) Calculate the true stress-strain curve according to the traditional method;

[0059] (3) According to the engineering stress-strain curv...

Embodiment 2

[0062] The following examples are for Al heat treated after rolling 0.3 CoCrFeNi (at.%) high entropy alloy, the rolling deformation is 75%, the annealing temperature is 800°C, and the annealing time is 1 hour.

[0063] The measurement Al of this embodiment 0.3 The method for the true stress of CoCrFeNi (at.%) high-entropy alloy comprises the following specific steps:

[0064] (1) Obtain the above-mentioned Al by static method (mechanical method) measurement 0.3 The Poisson's ratio of the CoCrFeNi high-entropy alloy μ=0.30;

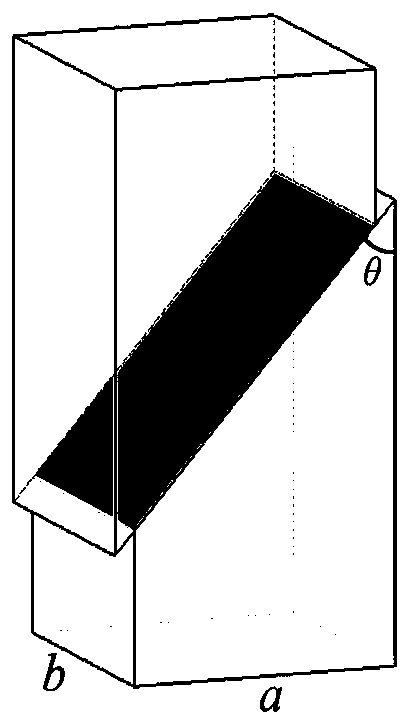

[0065] (2) Plate-shaped (square cross-section) Al 0.3 The original length l of CoCrFeNi high-entropy alloy 0 12.70mm, thickness 0.50mm, width 3.2mm, such as Figure 7 Shown; Utilize universal force mechanical testing machine to carry out uniaxial tension to sample, obtain load-displacement curve, calculate engineering stress-strain curve in conjunction with sample size, then utilize described formula (1) and (2) according to traditional method Calcul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com