Efficient annealing device for cable manufacturing

A technology for cable manufacturing and annealing device, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of low degree of automation and poor energy saving effect of annealing device, and achieve the effect of enhancing efficiency and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

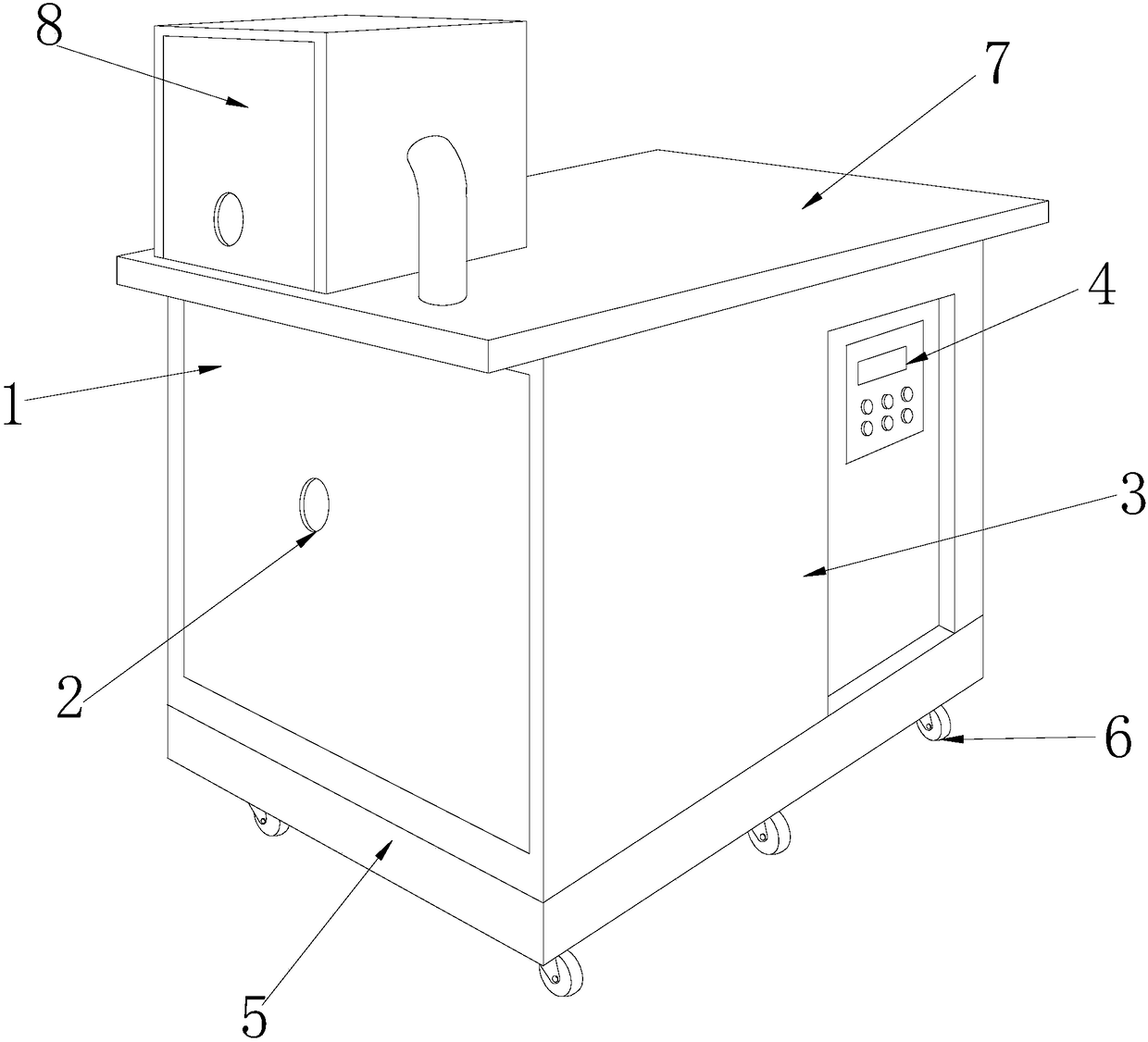

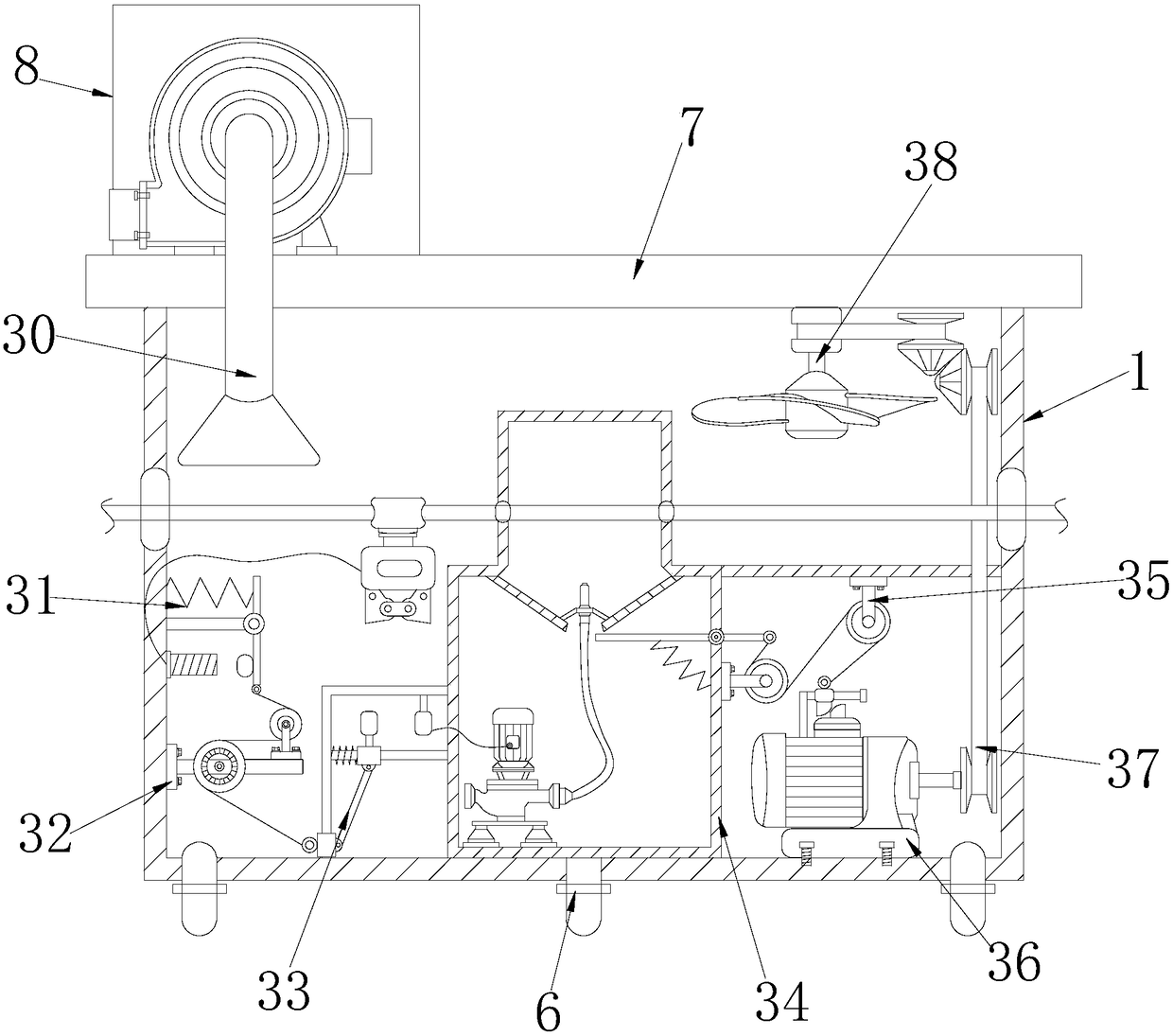

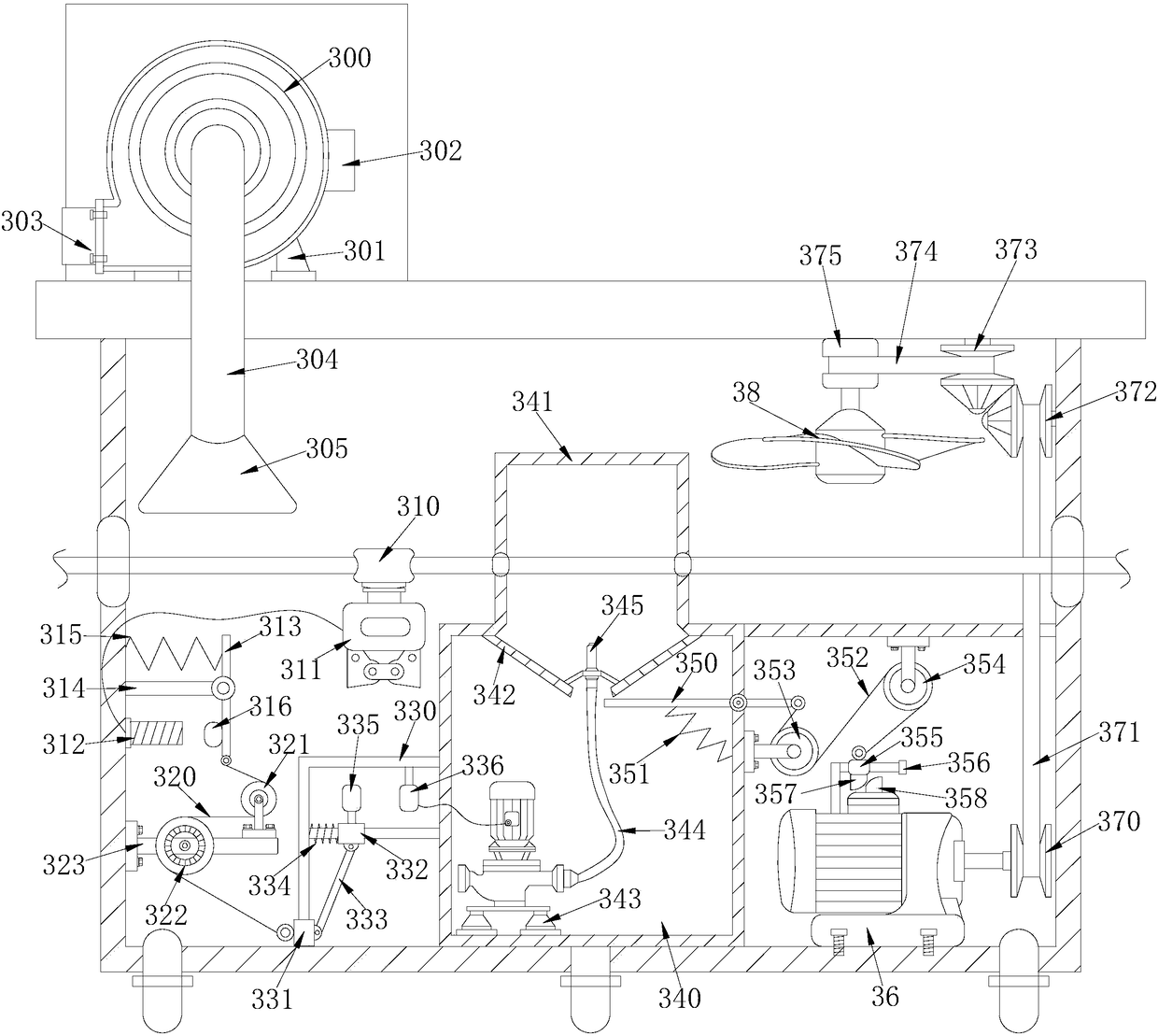

[0023] see Figure 1-Figure 4 , the present invention provides a technical solution for a high-efficiency annealing device for cable manufacturing: its structure includes a device main body 1, a cable core through hole 2, an energy-saving double annealing device 3, a control panel 4, a supporting base 5, a moving roller 6, and a device table 7. The fan box 8, the device main body 1 has a rectangular structure, the cable core penetration opening 2 is provided on the left and right side surfaces of the device main body 1 and is integrally formed with the device main body 1, and the energy-saving double annealing device 3 is set Inside the device main body 1, the control panel 4 is embedded in the right part of the front surface of the device main bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com