Spatially adjustable fixture for fixing mandibular models of different sizes

A technology for adjusting the space and the mandible, which is applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of biological damage and inconvenience of the mandible, and achieve the effect of rapid assembly, flexible connection, and multi-degree-of-freedom adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

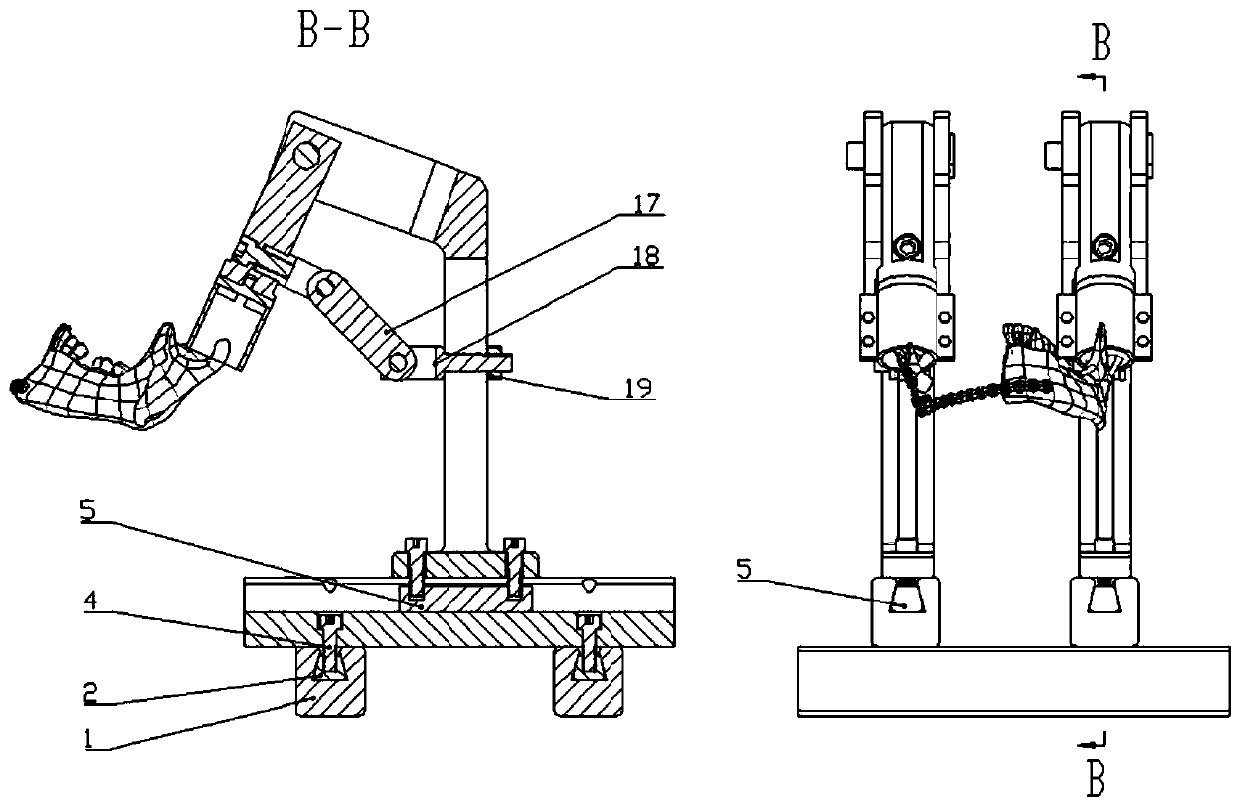

[0019] The following is attached Figure 1-4 Specific embodiments of the present invention will be described in detail.

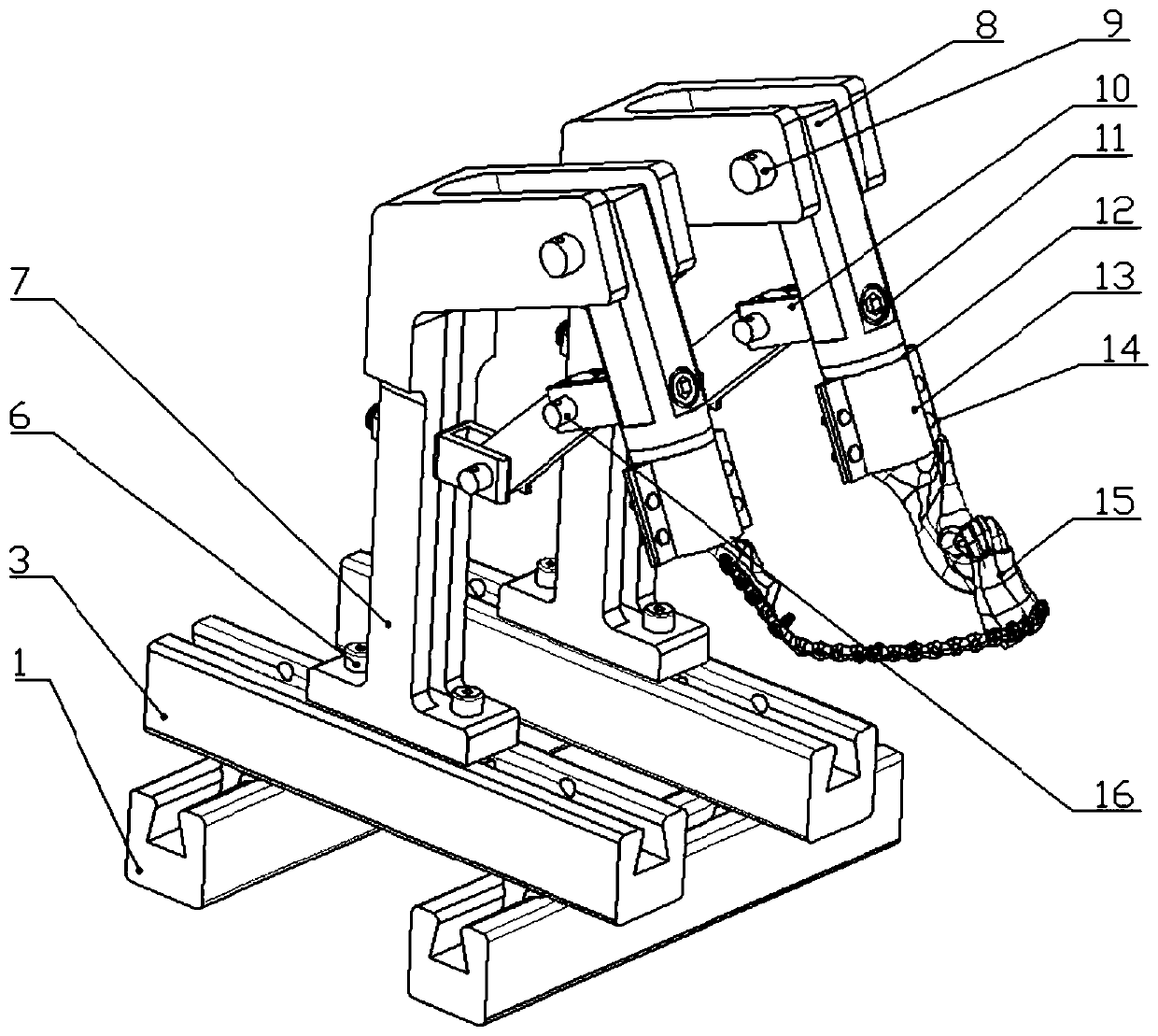

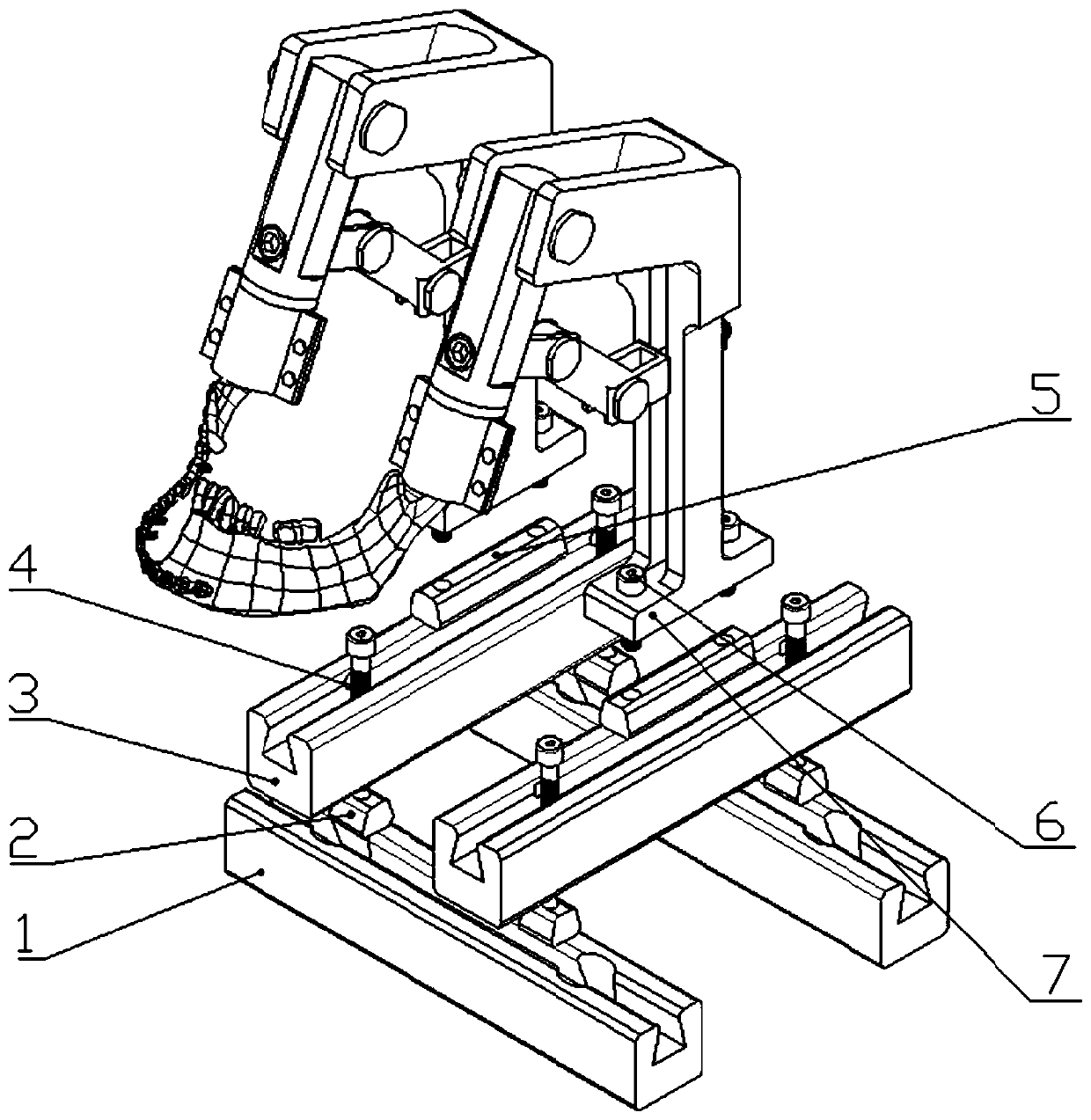

[0020] Such as figure 1 As shown, this embodiment provides an adjustable spatial position fixture for fixing mandibular models of different sizes, including: a sliding adjustment mechanism, a rotation and up and down sliding adjustment mechanism.

[0021] Such as image 3 The sliding adjustment mechanism includes a sliding groove 1, a sliding slider 2, an upper chute 3, an upper and lower hexagon socket bolt 4, an upper sliding block 5, an upper chute and a column connecting bolt 6, and a column 7.

[0022] The sliding groove 1 can be fixed on the bottom of the testing machine with hexagon socket bolts. The connection between the upper sliding groove 3 and the sliding groove 1 is through the cooperation of the two sliding sliders 2 stuck in the sliding groove 1, and then tightened with the upper and lower groove socket bolts 4. pinned into lower slider 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com