Buffering device for textile machine

A technology of textile machinery and buffer devices, applied in mechanical equipment, springs, shock absorbers, etc., can solve problems such as poor shock absorption effect and high noise, and achieve the effect of avoiding cylinder explosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

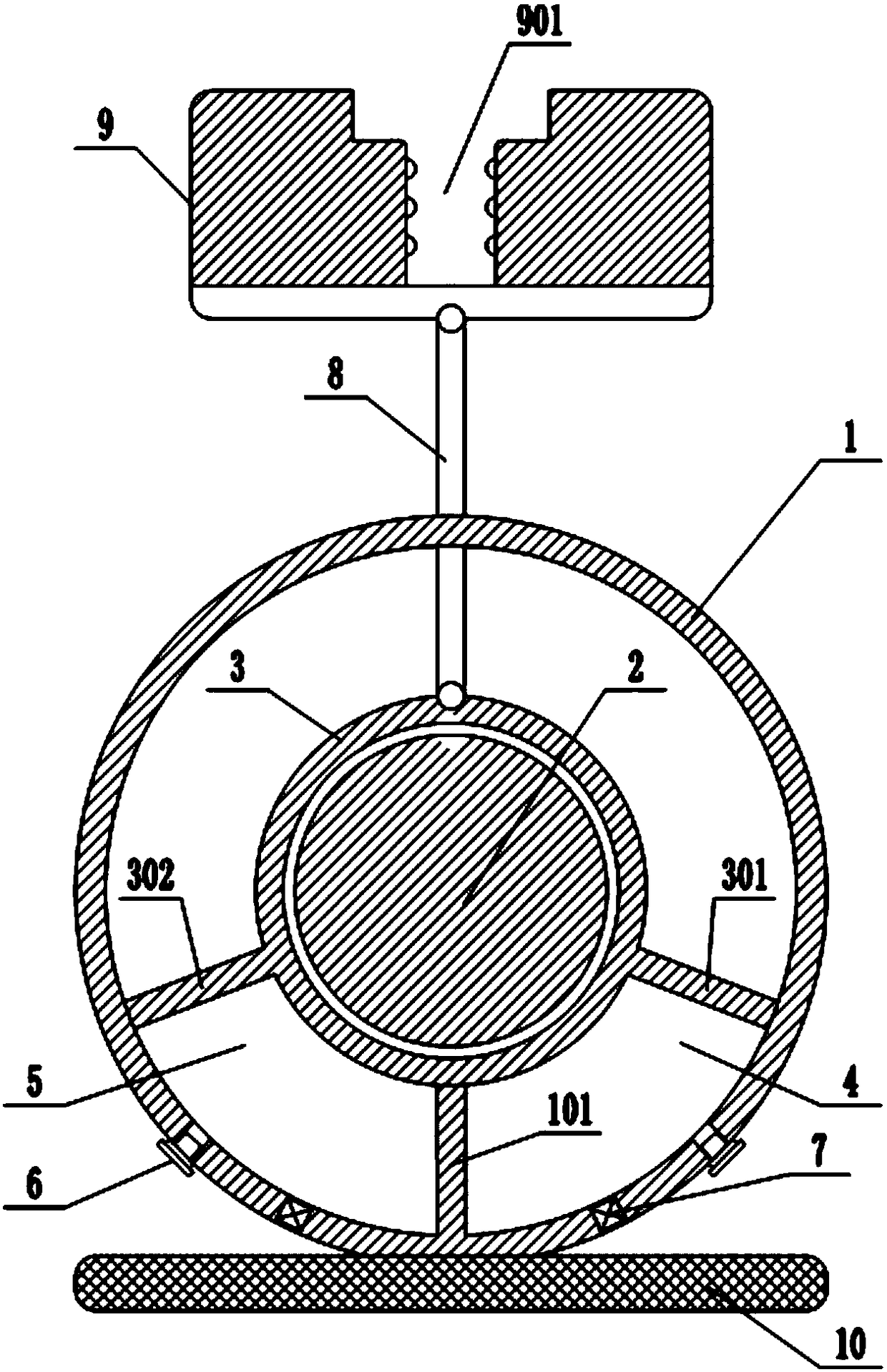

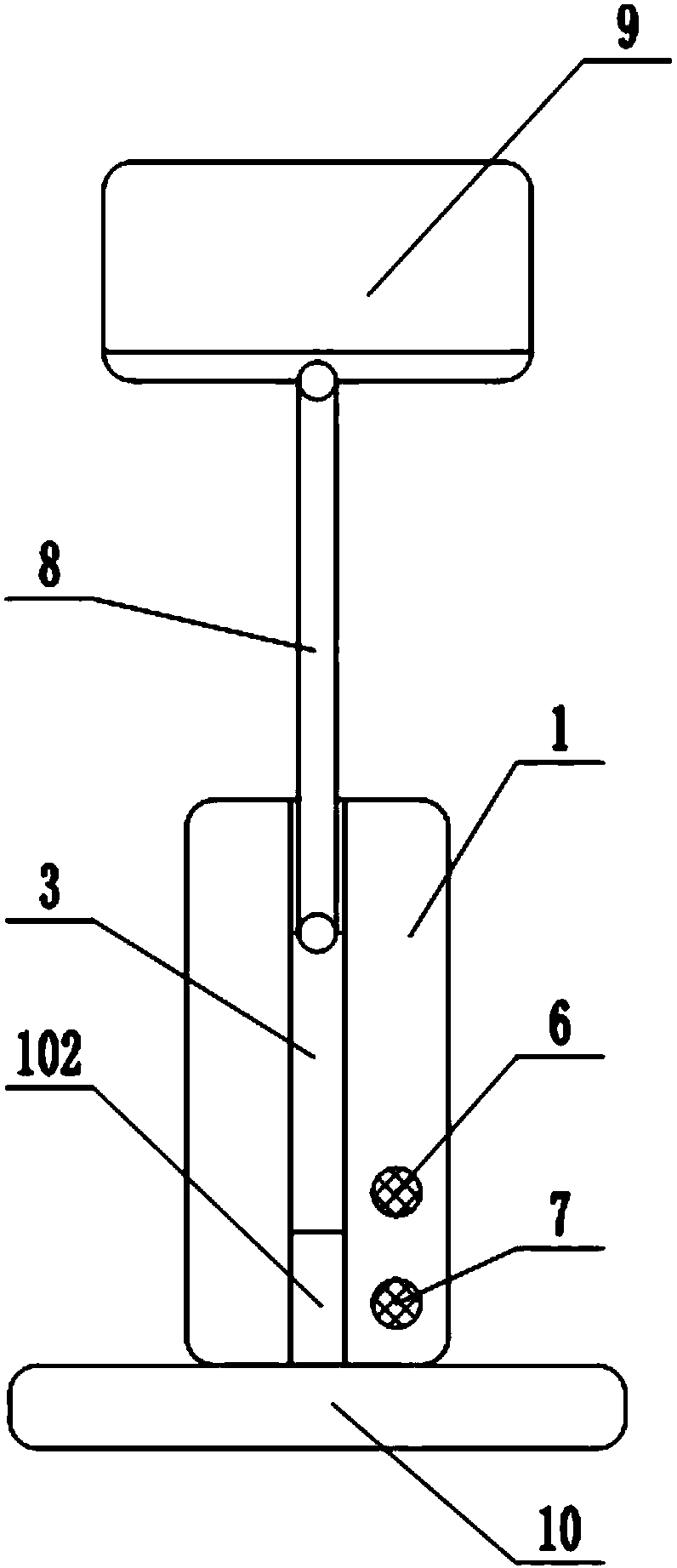

[0016] The reference signs in the drawings of the description include: supporting cylinder 1, barrier plate 101, strip opening 102, supporting shaft 2, roller 3, first pressing plate 301, second pressing plate 302, first compression chamber 4, second pressing plate Two compression chambers 5, oil inlet nozzles 6, safety valves 7, support rods 8, fixed blocks 9, placement grooves 901, and elastic blocks 10.

[0017] The embodiment is basically as attached figure 1 , attached figure 2 Shown: a buffer device for textile machinery, including a cylindrical support cylinder 1 with a hollow structure, a support shaft 2 is arranged inside the support cylinder 1 along the axis of the support cylinder 1, and the outer surface of the support shaft 2 is coaxially rotatable and connected There is a drum 3; the inner wall of the lower end of the support cylinder 1 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com