Low-heat elastic damping two-end-fixed micro-beam resonator with through hole structure

A technology of micro-beam resonator and elastic damping, which is applied in the direction of impedance network and electrical components, and can solve the problems such as difficult to change the working frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

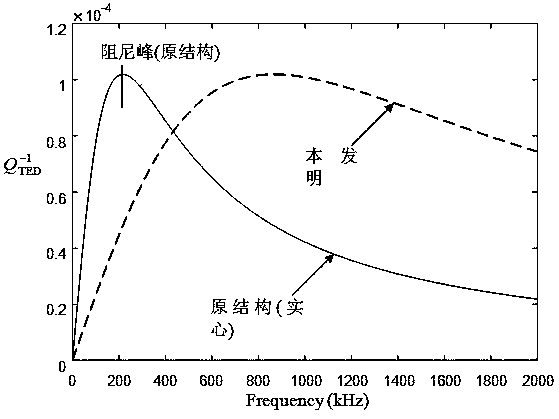

[0023] The present invention provides a low thermoelastic damping microbeam resonator fixed at both ends with a through-hole structure. The microbeam device of the present invention adopts a narrow and long rectangular through-hole structure, which physically reduces the thickness of the beam, so that the thermoelastic damping peak appears higher The frequency band avoids the operating frequency (in the low frequency band), thereby significantly reducing thermoelastic damping, that is, significantly reducing energy loss.

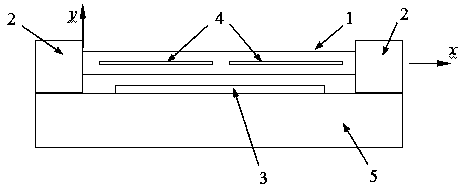

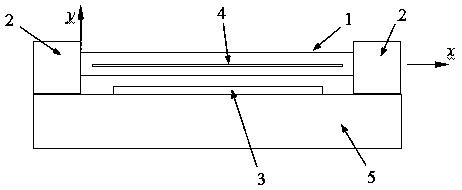

[0024] The present invention as figure 1 The shown low thermoelastic damping bending vibration microbeam device with a narrow and long rectangular through-hole structure includes a base 5 , a low thermoelastic damping structure arranged on the base 5 , and a driving electrode 3 . The low thermoelastic damping structure inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com