Special tooling for jack block processing and assembly structure for jack block processing

A jacking block and tooling technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as inability to repair a single piece, increase repair cost, and long processing time, so as to achieve convenient clamping and improve production efficiency , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

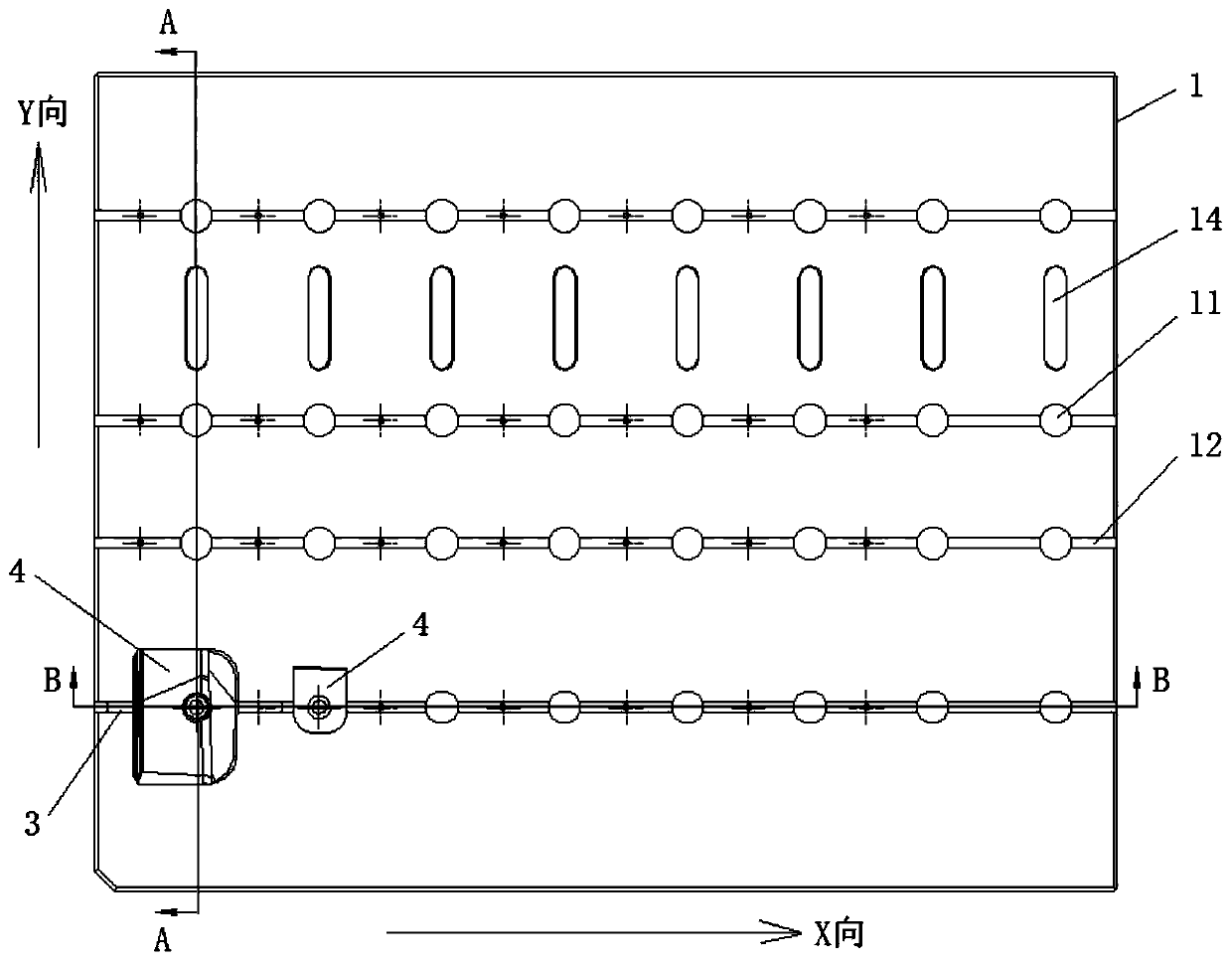

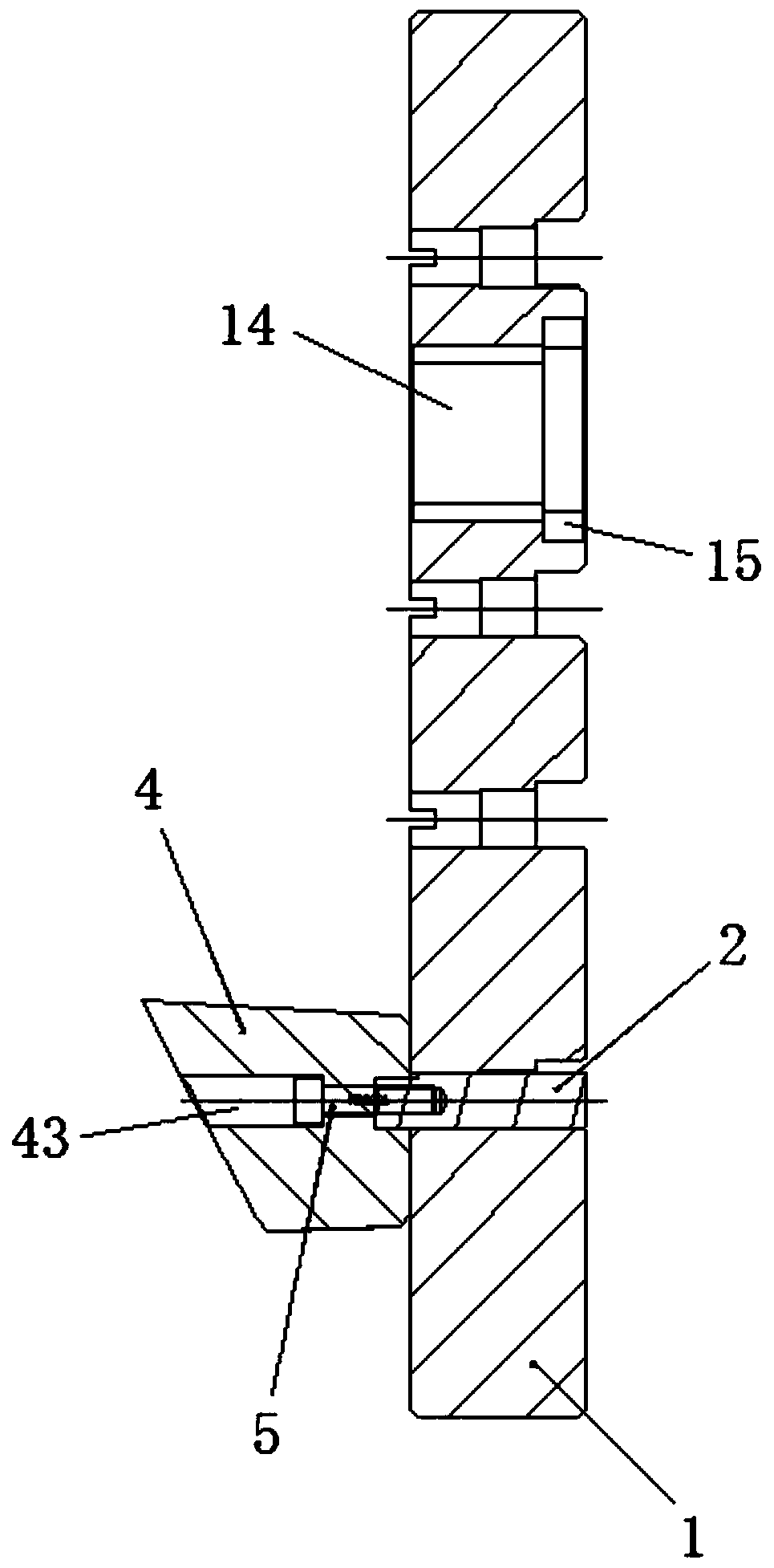

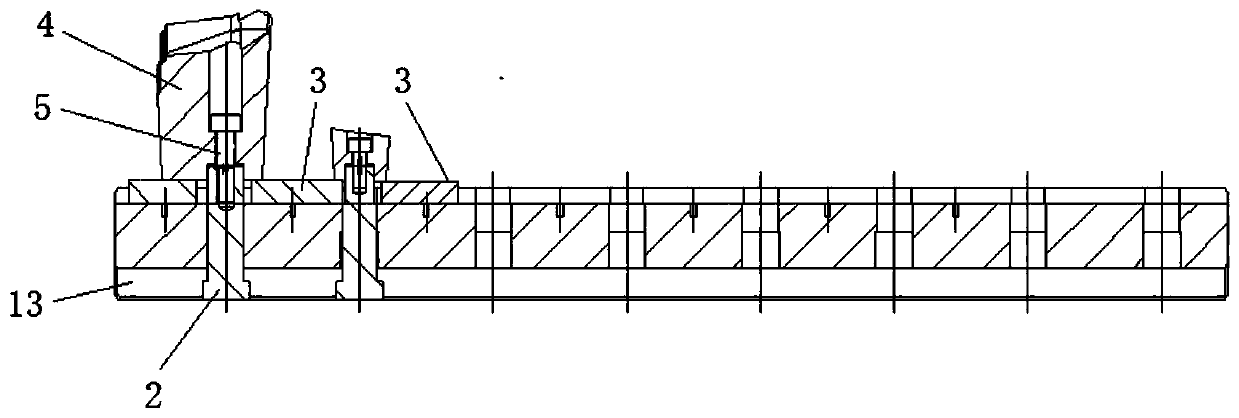

[0028] The invention discloses a special tooling for jack block processing, such as Figure 1-5 As shown, it includes a process plate 1, a cylindrical locating pin 2 and a square locating pin 3. The process plate is provided with a number of cylindrical pin holes 11 that penetrate up and down. The upper and lower planes of the process plate are respectively provided with upper flat bottoms. Groove 12 and lower flat-bottomed groove 13, the cross-section of upper and lower flat-bottomed grooves all is rectangular. The cylindrical pin hole runs through the upper flat-bottomed groove and the lower flat-bottomed groove, the groove width of the lower flat-bottomed groove is greater than the diameter of the cylindrical pin hole, and the groove bottom area of the lower flat-bottomed groove around the cylindrical pin hole is used as The axial positioning surface of the cylindrical positioning pin. The upper end of the cylindrical positioning pin is axially provided with a screw hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com