Manufacturing method of micro-drive robot arm

A robotic arm and micro-drive technology, applied in manipulators, program-controlled manipulators, claw arms, etc., can solve the problems of insufficient detection sensitivity of piezoelectric materials, long post-processing/assembly iterations, etc., to improve stability, eliminate response lag, The effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

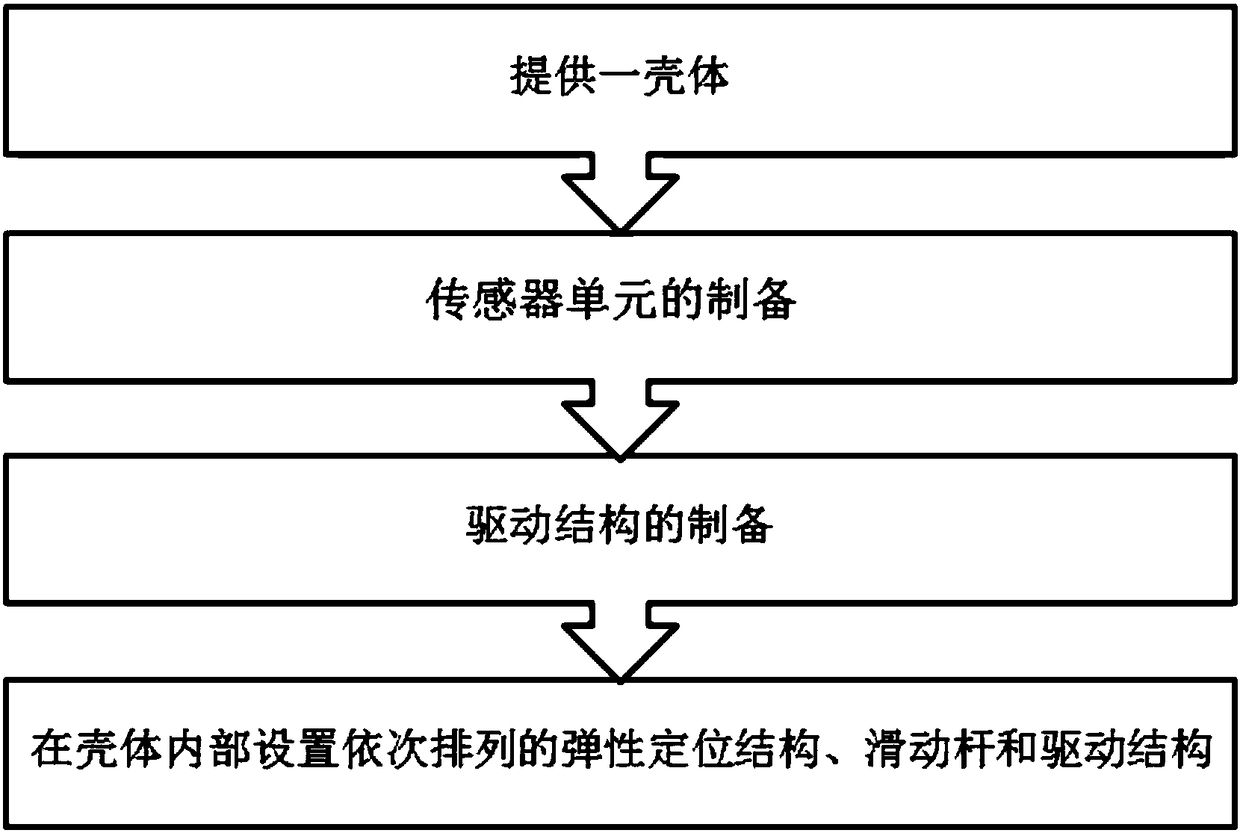

[0023] A flow chart of the preparation of a micro-actuated robot arm is shown in figure 1 shown. Firstly, a casing 1 is provided, and the casing 1 includes through holes at its two ends;

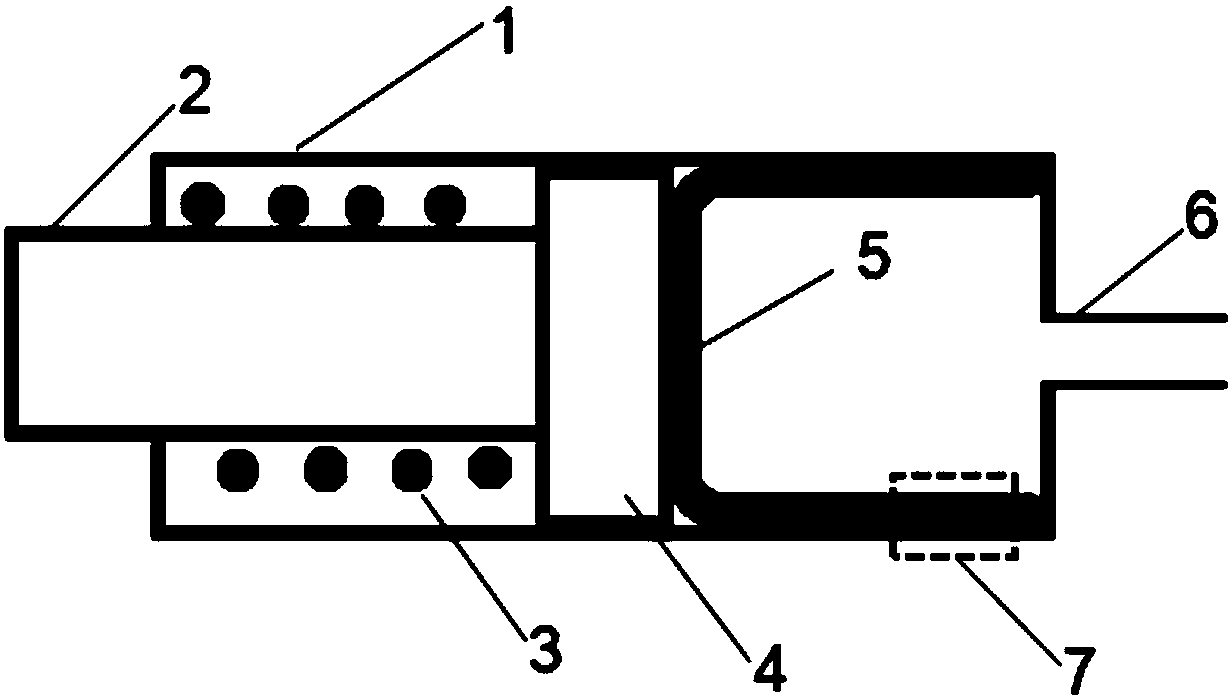

[0024] Inside the housing 1, an elastic positioning structure 3, a sliding rod 2 and a driving structure 5 arranged in sequence are arranged, wherein the elastic positioning structure 3 is used for elastically positioning the sliding rod 2, and the sliding rod 2 is positioned on the The through hole at one end of the housing 1 protrudes, and the driving structure 5 is connected with a driving tube 6, and the driving tube 6 is connected to the driving structure 5 through the through hole at the other end of the housing 1;

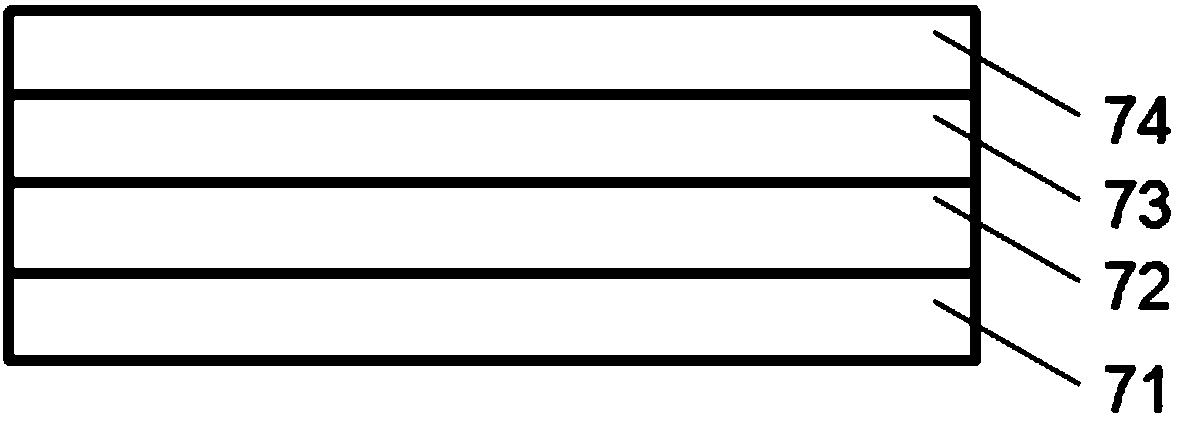

[0025] The driving structure 5 is a cavity structure made of polydimethylsiloxane, and the cavity structure is placed in a mold by placing liquid polydimethylsiloxane in the side wall of the cavity structure. The sensor unit 7 is implanted, and the driving structure 5 is...

Embodiment 2

[0028] Embodiment 2 provides a support arm structure 3, two opposing micro-drive robot arms 11 and 12 are arranged on one side of the support arm structure 3, and the clamping operation of the object can be realized by utilizing the expansion and contraction of the two micro-drive robot arms ,Such as Figure 5 As shown, wherein the micro-driven robot arms 11 and 12 are prepared by the method described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com