Processing device for wooden plate

A technology for processing devices and wood boards, which is applied to wood processing equipment, adhesive application devices, manufacturing tools, etc., can solve the problems of reduced processing efficiency, unfavorable batch processing of wood boards, and non-adjustable length of gluing rollers, so as to improve processing efficiency and ensure The effect of full glue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below through specific implementations:

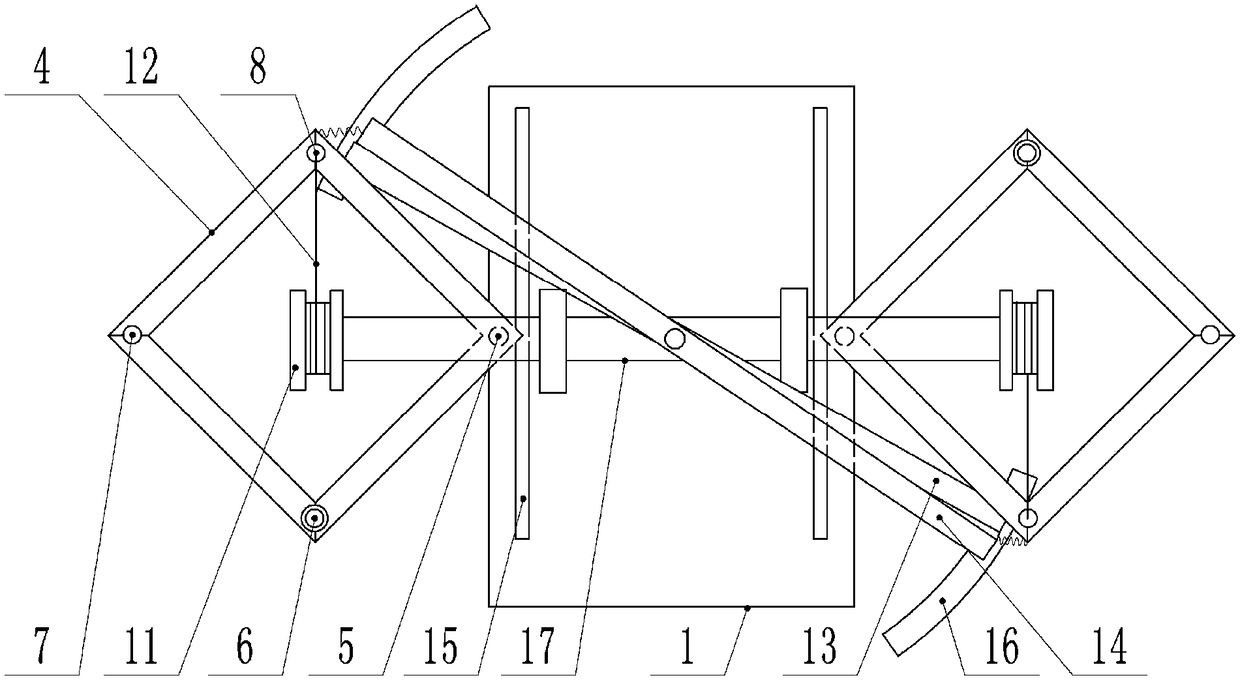

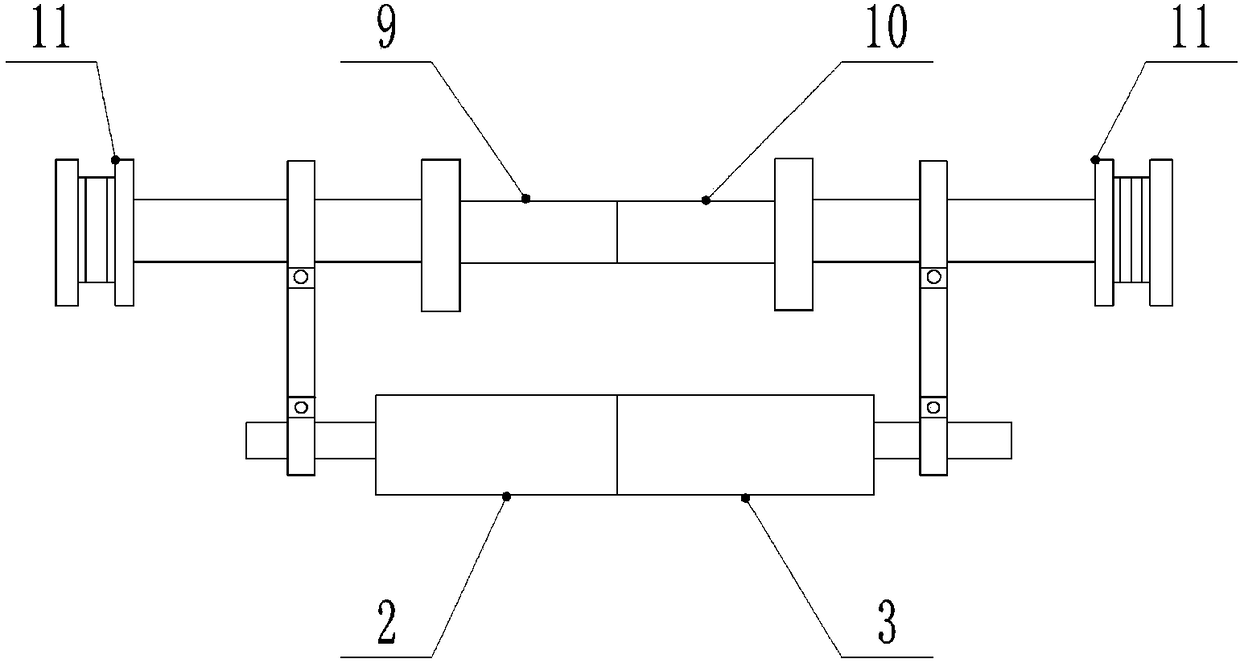

[0020] The reference signs in the drawings of the specification include: transfer table 1, first roller 2, second roller 3, frame 4, extrusion angle 5, fixed angle 6, free angle 7, sliding angle 8, first shaft 9, second The second shaft 10, the reel 11, the draw rope 12, the fixed rod 13, the swing rod 14, the extrusion plate 15, the arc rail 16, and the sliding shaft 17.

[0021] Implementation example figure 1 Shown: a processing device for wood boards, including a transfer table 1, a rubber roller, an adjustment mechanism, a sliding mechanism and a blowing mechanism.

[0022] The transfer table 1 is used to transfer wood boards to be processed.

[0023] The glue roller is used to apply glue to the wood board by rotating under the drive of an external power such as a motor. Its structure combines such as figure 2 As shown, it includes a first roller 2 and a second roller 3 sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com