Packaging cup sealing device with accurate sealing film alignment and high flatness

A technology of sealing device and sealing film, which is applied in the direction of packaging material feeding device, packaging sealing/fastening, packaging, etc., which can solve the problems that the sealing film affects the appearance, the appearance of the packaging cup is reduced, and the sealing film is wrinkled, etc., to achieve a sense of quality Obvious, strong tension, the effect of overcoming wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

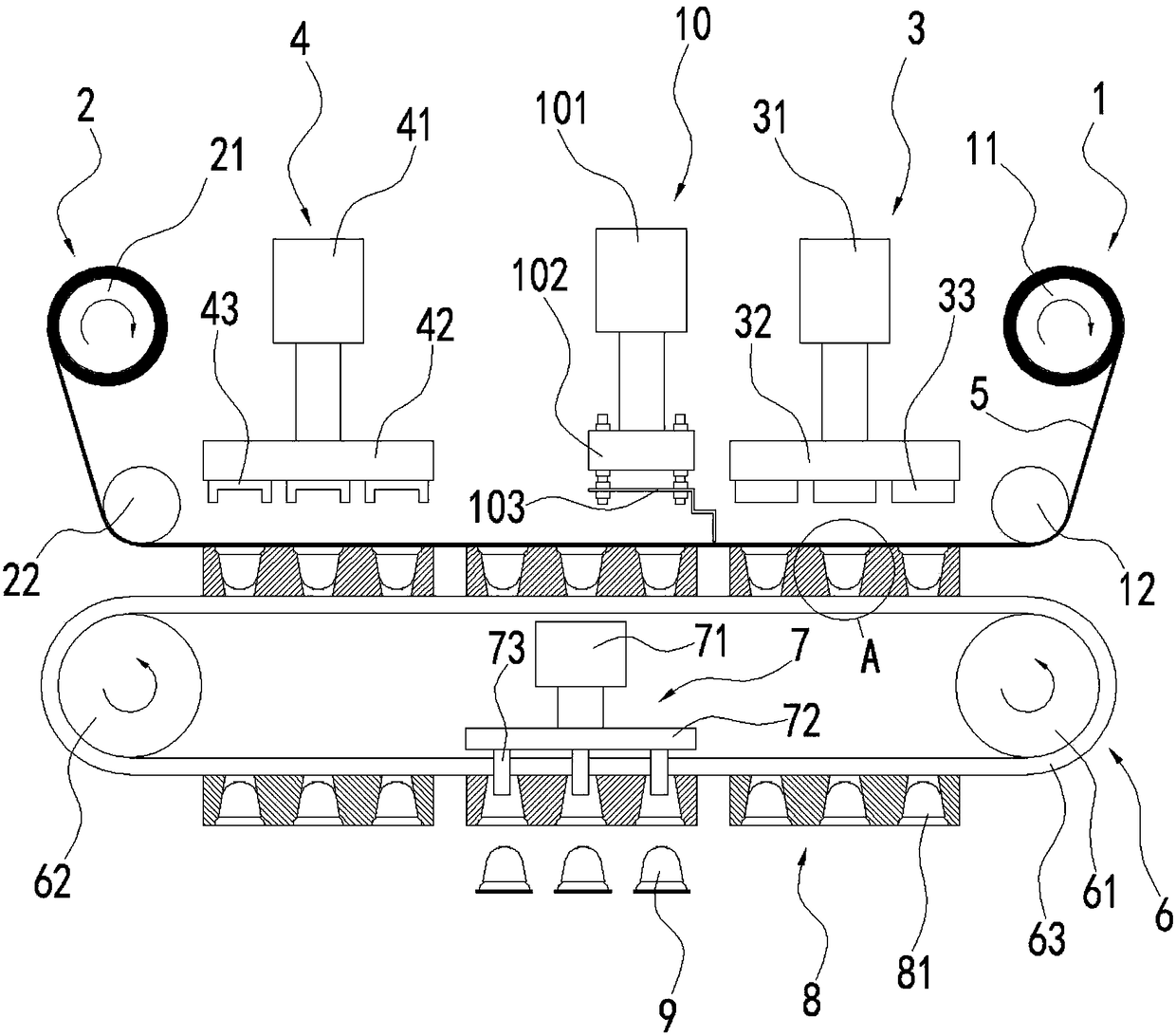

[0022] In order to make the purpose of the present invention, technical solutions and advantages clearer, the following will combine figure 1 - Figure 4 The accompanying drawings describe the present invention in further detail.

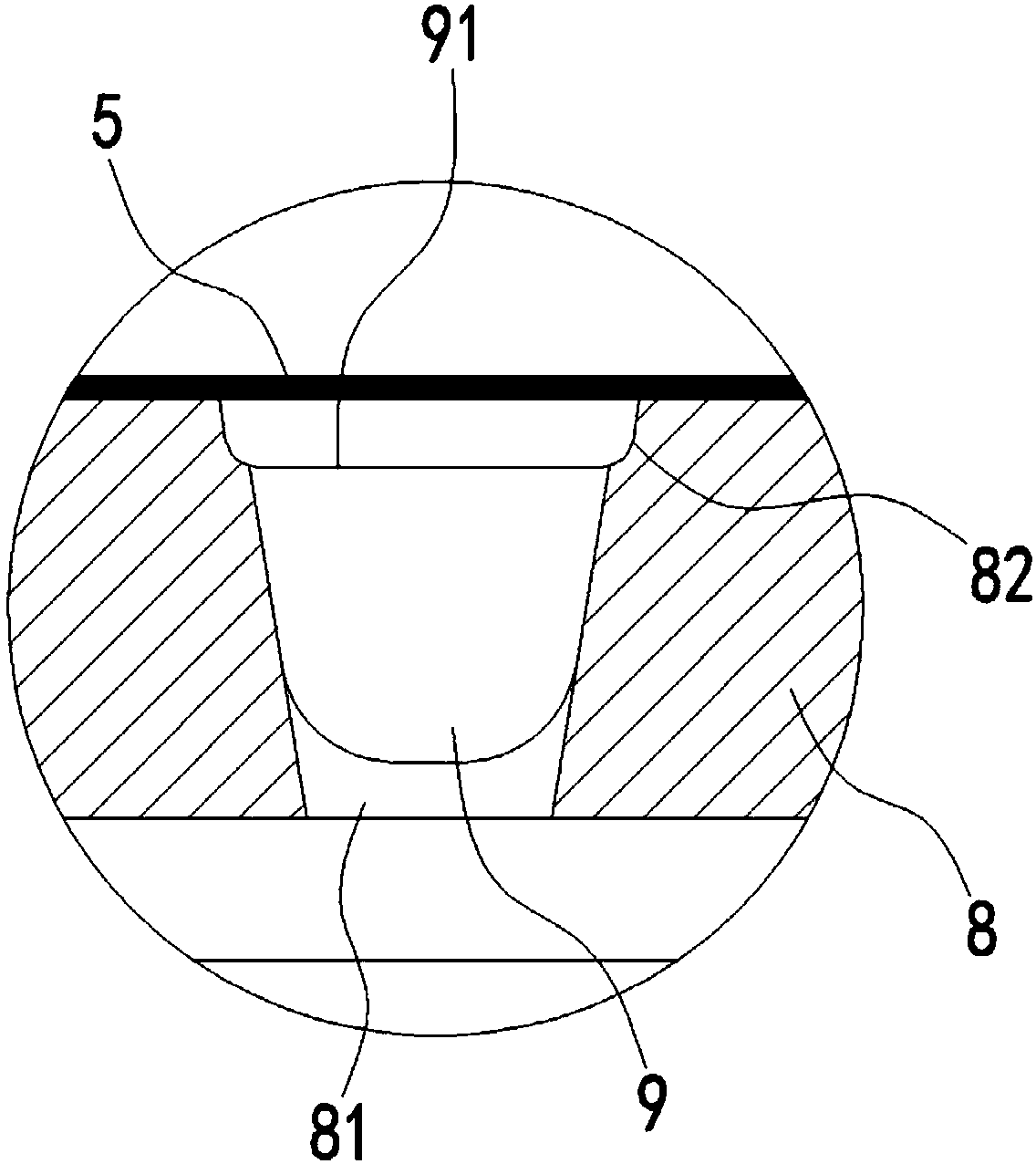

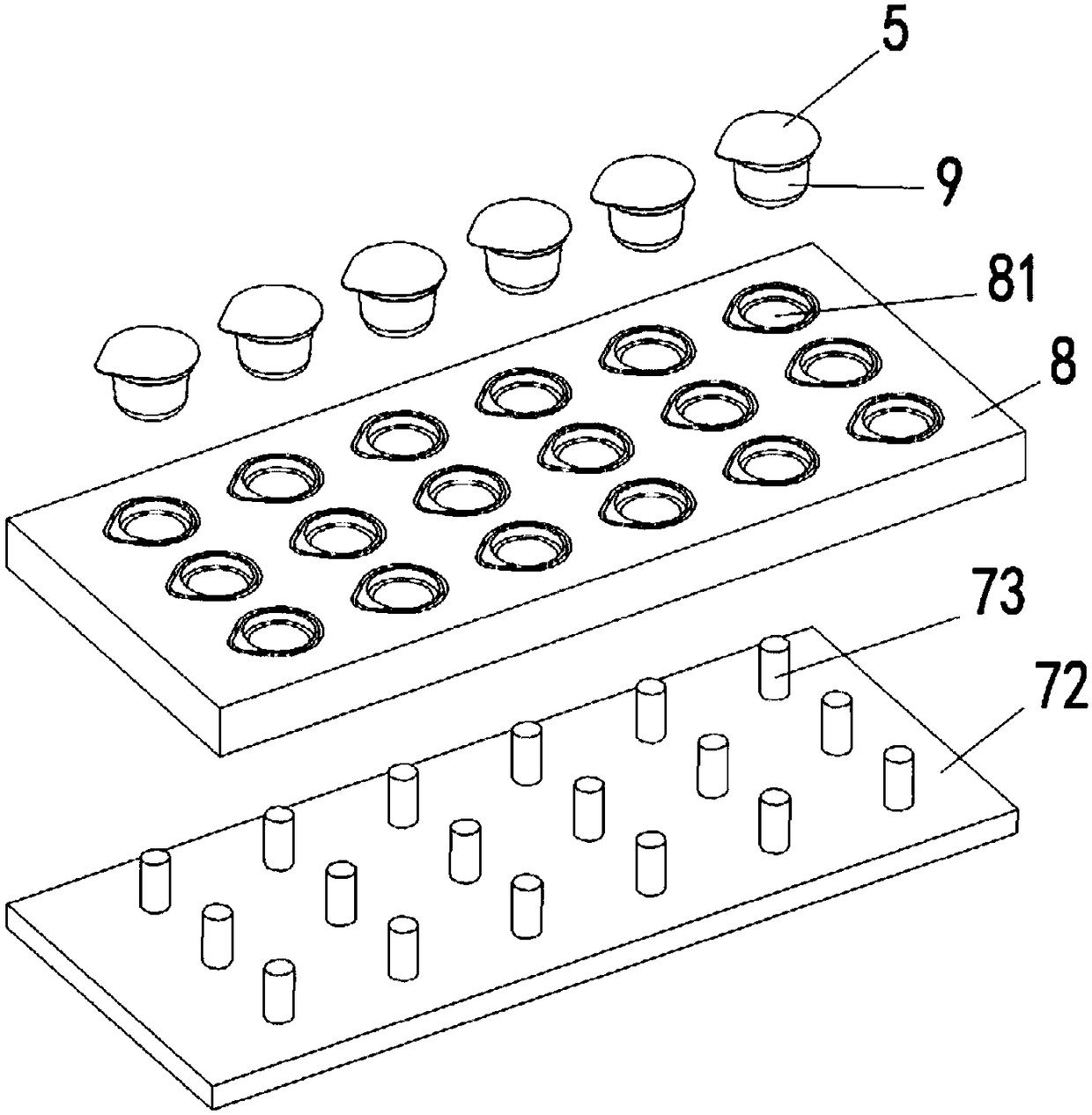

[0023] refer to figure 1 - Figure 4 As shown, a packaging cup sealing device with accurate sealing film alignment and high flatness includes a film feeding device 1, a film collecting device 2, a hot pressing device 3, an edge trimming device 4, a sealing film 5, a clamp delivery device 6, Ejecting device 7, packaging cup fixture 8, flattening and aligning device 10.

[0024] The two ends of the sealing film 5 are respectively connected to the film feeding device 1 and the film receiving device 2 and move from the film feeding device 1 to the film receiving device 2. A hot pressing device 3, a pressing device 3 and a pressing device 3 are sequentially arranged above the sealing film 5 along the moving direction of the sealing film 5. Flat align...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com