Joint of metal and plastic pipe line and making method thereof

A technology for pipe joints and metal pipes, applied in the direction of pipes/pipe joints/fittings, sleeves/sockets, passing elements, etc., which can solve the problem of difficult control of the heating temperature range and loose contact between plastic bobbins and metal parts. , non-applicable and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The technical solution of the invention will be further described in detail below in conjunction with the accompanying drawings.

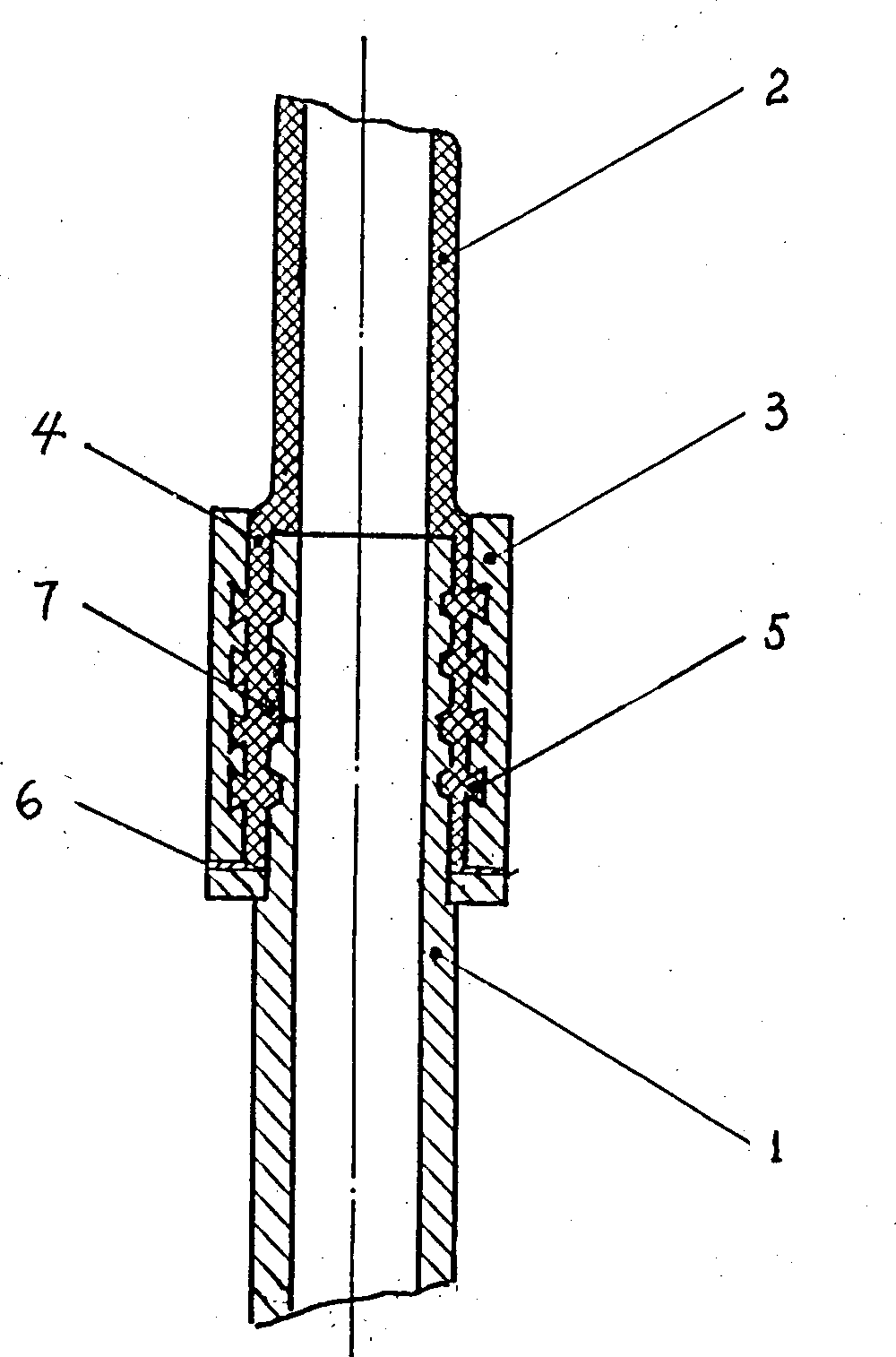

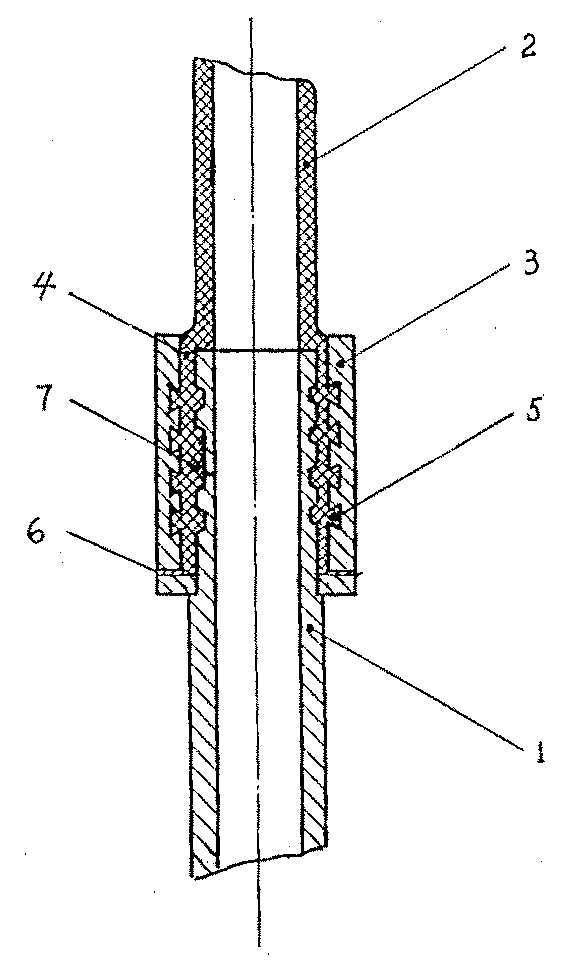

[0009] as attached figure 1 As shown, the metal-plastic pipeline joint of the present invention includes a metal pipe section 1 and a plastic pipe section 2, and an outer metal sleeve 3 concentric with the metal pipe section is sleeved at one end of the metal pipe section. The inner end of the outer metal sheath 3 is in a closed state with the metal pipe section, and the outer end of the outer metal sheath is slightly longer than the metal pipe section open end, so that the outer metal sheath and the metal pipe section this end just form a semi-closed annular cavity 4. The outer wall of the annular cavity 4 is the inner wall of the outer metal sheath, and the inner wall of the annular cavity is the outer wall of the metal pipe section. Several grooves 5 are arranged on both side walls inside the annular cavity. One end of the plastic pipe ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap