Pipeline fast cutoff device

A shut-off device and fast technology, applied in valve devices, valve operation/release devices, pipe components, etc., can solve problems such as pipe bursting, loose pipe joints, waste of raw materials, etc., and achieve the effect of convenient emergency use and waste prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention can be explained in more detail through the following embodiments. The purpose of disclosing the present invention is to protect all changes and improvements within the scope of the present invention. The present invention is not limited to the following embodiments;

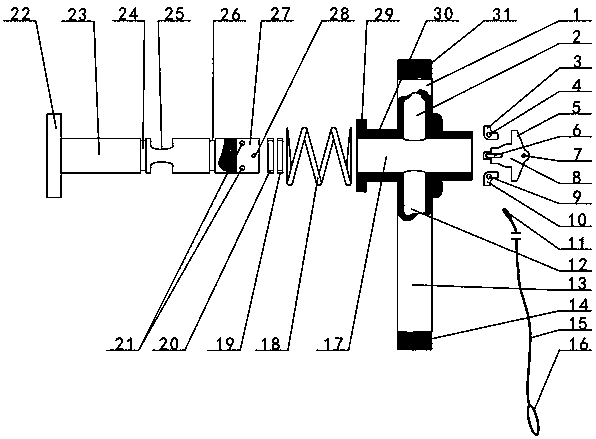

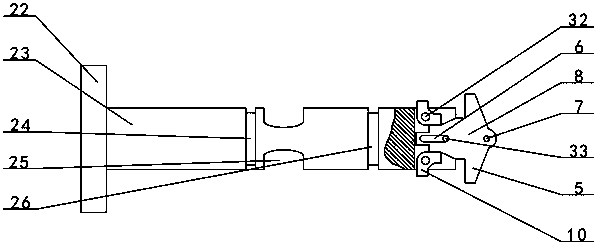

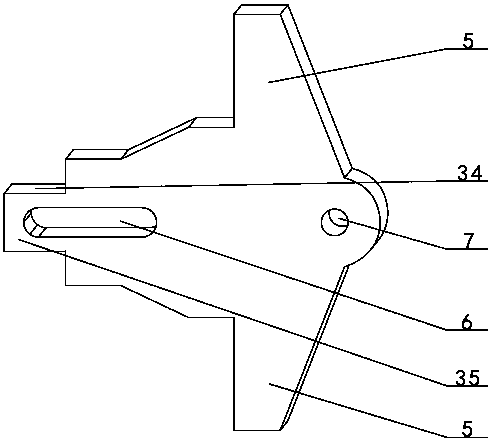

[0026] Attached Figure 1~5 The described pipeline quick cut-off device includes a cross-shaped tube, a movable valve stem 23, a rubber sealing ring A19, a rubber sealing ring B20, a spring 18, a corner plate A 3, a corner plate B 10, and a pull plate 8. An expanding ring 22 is provided at one end of the movable valve stem 23, and an annular groove A24 and an annular groove B26 are respectively provided on both sides of the middle part close to the movable valve stem 23. The valve stem 23 is moved between the annular groove A24 and the annular groove B26. A liquid passage hole 25 is provided near the annular groove A24; the outer end of the connecting pipe A1 of the cross-shaped pipe is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com