Laser energy dynamic distribution model-based ablation depth solving method

A technology for distributing models and laser energy, used in laser welding equipment, complex mathematical operations, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The specific implementation manner of the present invention will be described in detail in conjunction with the technical scheme and the accompanying drawings.

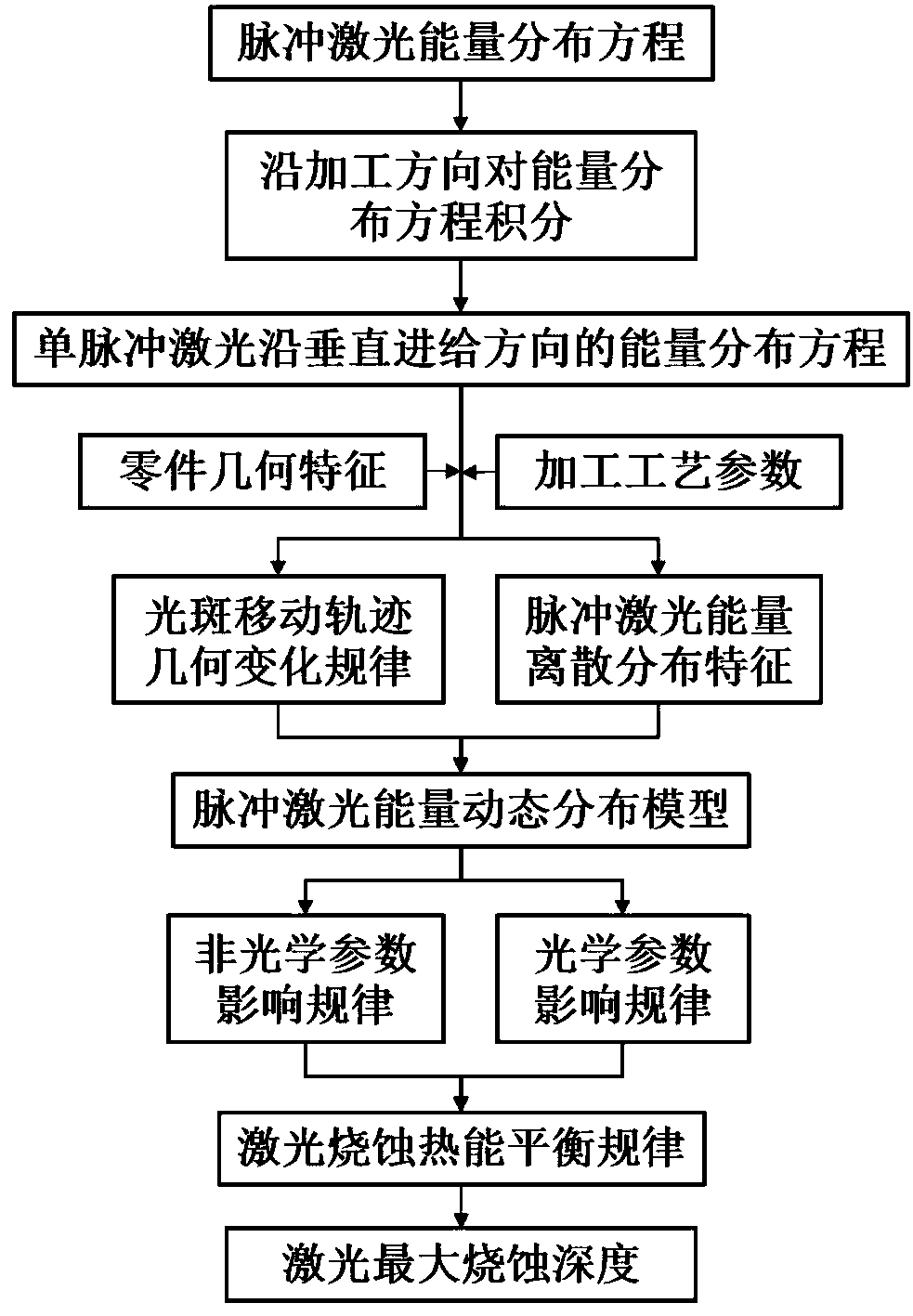

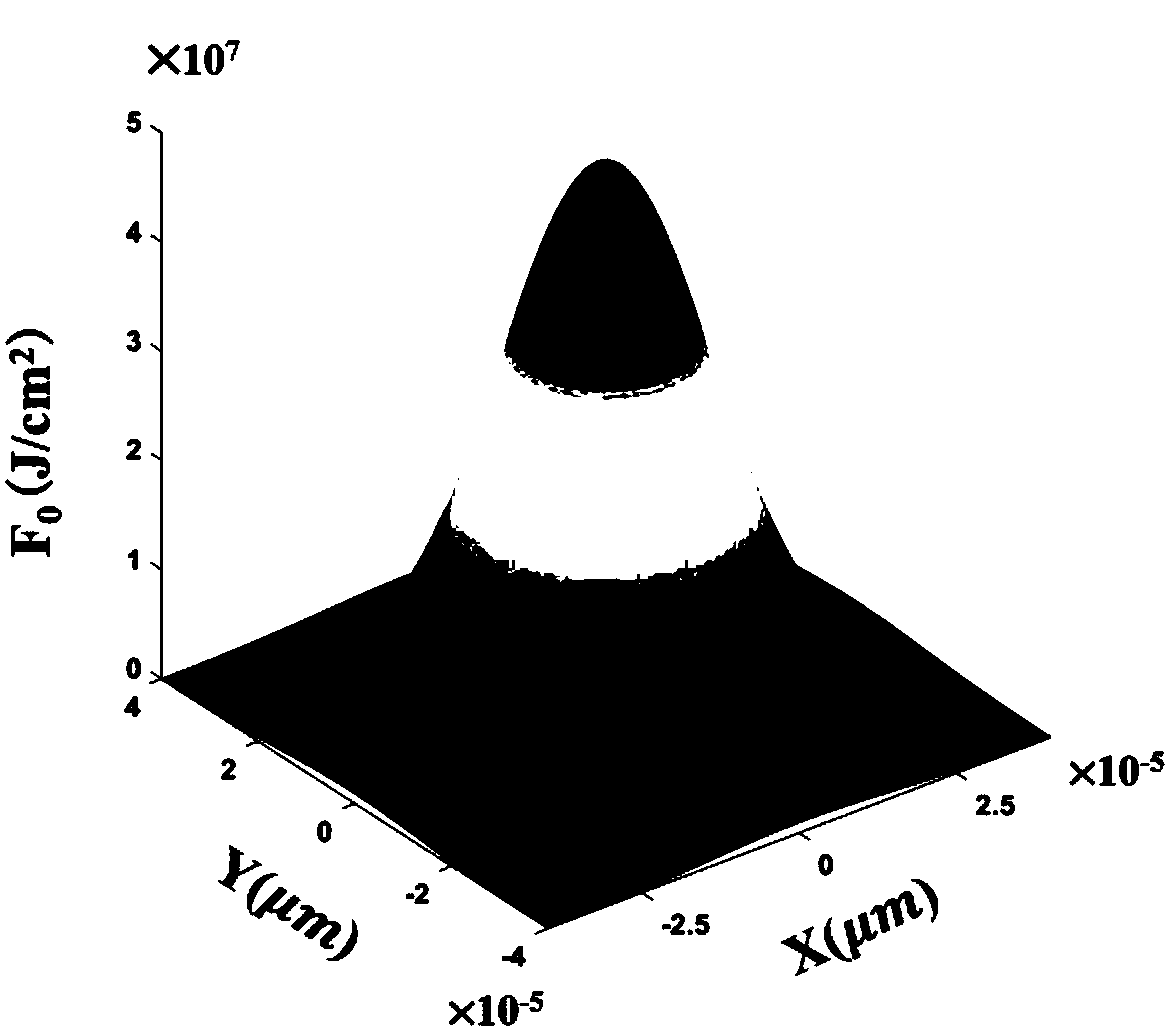

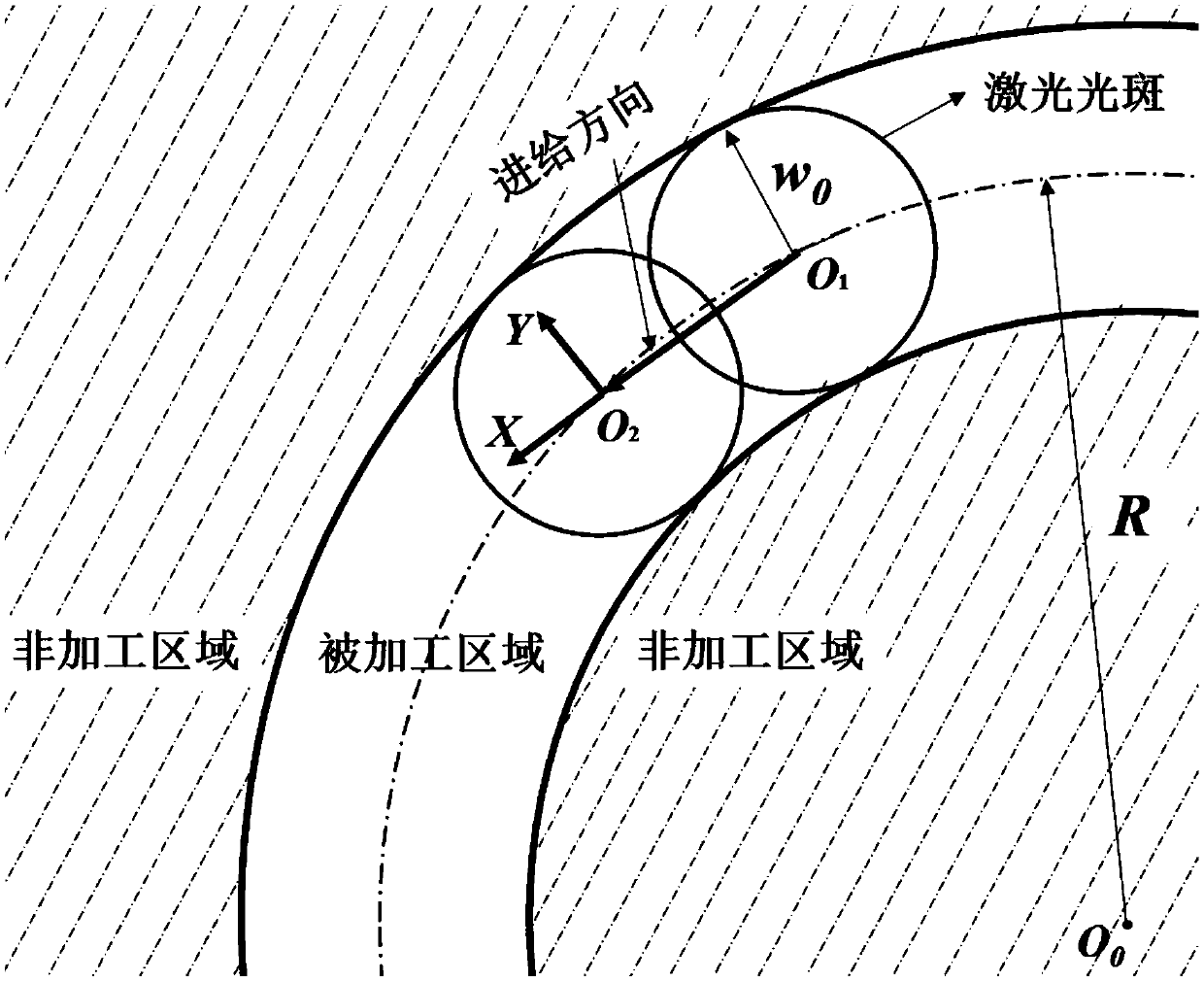

[0064] During pulsed laser processing, due to the characteristics of discrete distribution of laser energy and the change of geometric characteristics of the processing track, the single pulse laser energy distribution model or the simulation results of energy distribution cannot accurately describe the dynamic distribution of material surface energy. The maximum ablation depth solution method of the dynamic distribution model, according to the geometric variation law of the pulse laser spot moving track and the discrete distribution characteristics of the pulse laser energy, the dynamic distribution model of the part surface energy during pulse laser processing is established, and the pulse laser processing process is described. The dynamic distribution law of energy in the pulse laser processing, and this dyna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com