A method for preparing fireproof glass

A fireproof glass and glass technology, applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of low adhesion of fireproof liquid, poor anti-aging performance, affecting fire performance, etc., and achieve simple construction and adhesion. The effect of strengthening and increasing the cost of the manufacturing plant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 1. Prepare fireproof liquid

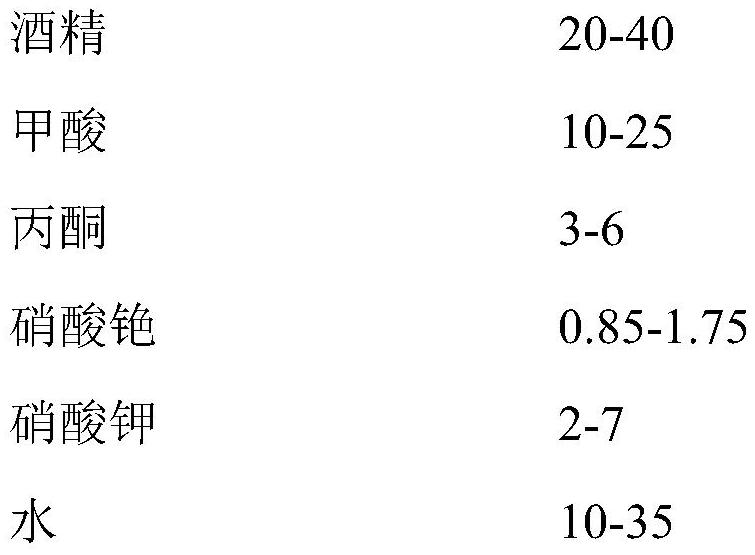

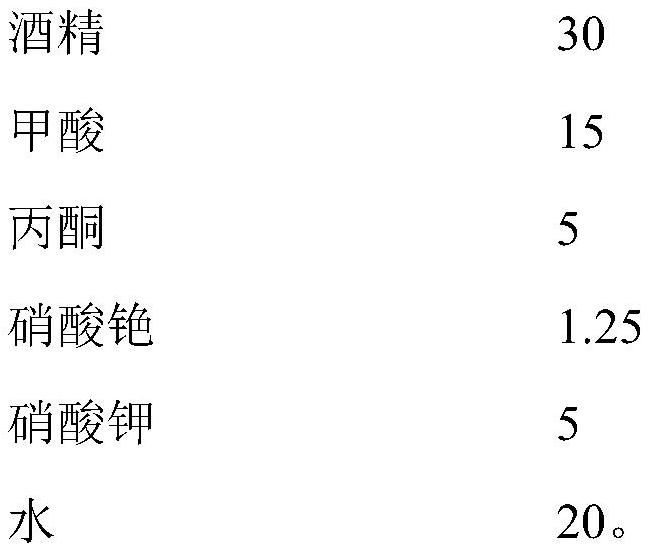

[0058] 1-1) Prepare the raw materials according to the following proportions by weight (kg)

[0059]

[0060] Wherein, the mass percent concentration of alcohol is 95% industrial alcohol;

[0061] 1-2) Add the raw material potassium nitrate into water, stir and mix evenly to make a potassium nitrate solution, wherein the stirring rate is 60rpm (usually 60-120rpm); the stirring time is 0.5h;

[0062] 1-3) Add alcohol, formic acid, acetone, and cesium nitrate to the potassium nitrate solution in sequence, stir with an electric stirrer, and perform mixing treatment, wherein the stirring rate is 60rpm (usually 60-120rpm); the stirring time is 1.0h;

[0063] 1-4) Stir and mix the mixed solution for 1.0 h, and place it still at a temperature of 25° C. to allow it to fully fuse with each other and undergo a chemical reaction. After standing for 48 hours, the fireproof liquid for glass is obtained.

[0064] 2. Replacement treatment

[0065] 2...

Embodiment 2

[0084] 1. Prepare fireproof liquid

[0085] Same as Example 1

[0086] 2. Replacement treatment

[0087] Except for the thickness of the float glass which is 12mm, the fire protection composition is sprayed in an amount of 10g / m 2 Except, all the other are identical with embodiment 1;

[0088] 3. Cleaning and drying

[0089] Same as Example 1

[0090] 4. Tempering treatment

[0091] Except that the preheating temperature in step 4-1) is 450°C; the glass moves back and forth in the furnace at a speed of 90-210mm / s, and the preheating treatment is 355s to obtain the preheating glass; wherein: the top hot air convection intensity: 1%~ In the 50% convective heating time interval (that is, from the time when the glass enters the tempering furnace to the 177.5s after entering), the convective pressure intensity of the top hot air is uniformly reduced from 1.8bar to 1.2bar; The convective pressure intensity of the hot air at the top during the 177.5s to 248.5s after entering th...

Embodiment 3

[0096] 1. Prepare fireproof liquid

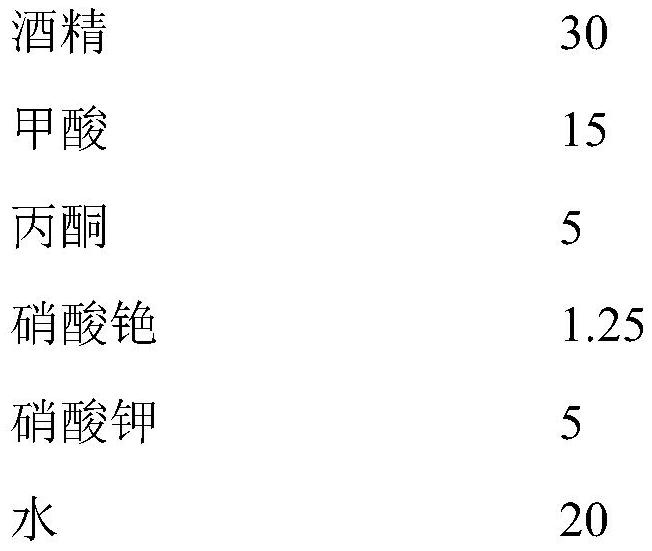

[0097] 1-1) Prepare the raw materials according to the following proportions by weight (kg)

[0098]

[0099] Wherein, the mass percent concentration of alcohol is 95% industrial alcohol;

[0100] 1-2) Add the raw material potassium nitrate into water, stir and mix evenly to make a potassium nitrate solution, wherein the stirring rate is 100rpm (usually 60-120rpm); the stirring time is 0.5h;

[0101] 1-3) Add alcohol, formic acid, acetone, and cesium nitrate to the potassium nitrate solution in sequence, stir with an electric stirrer, and perform mixing treatment, wherein the stirring rate is 100rpm (usually 60-120rpm); the stirring time is 1.5h;

[0102] 1-4) Stir and mix the mixed solution for 1.5 hours, and place it at a temperature of 20° C. to allow it to fully fuse with each other, and leave it to react for 60 hours to obtain the fireproof liquid for glass.

[0103] 2. Replacement treatment

[0104] 2-1) Evenly spray the firepro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface stress | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com