Synchronizer gear engagement process control method based on unilateral pressure control system

A technology of pressure control and process control, which is applied in the direction of transmission control, components with teeth, belts/chains/gears, etc. It can solve the problems of inability to deal with the decline of control performance, and achieve the effect of reducing repeated gearing failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

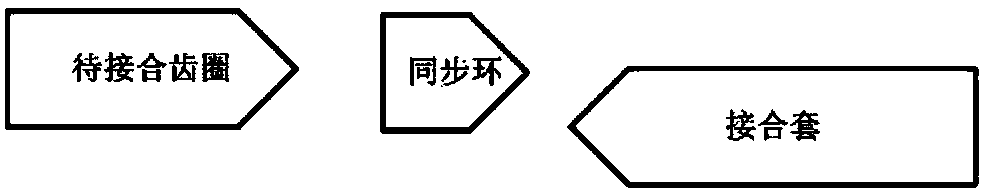

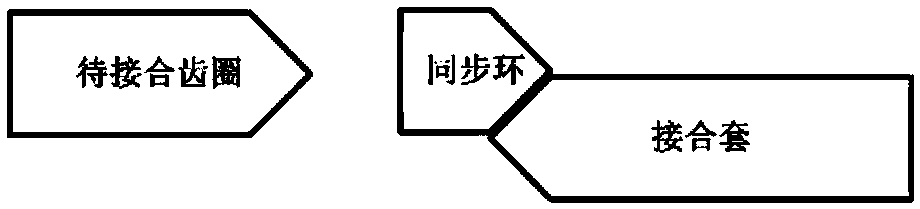

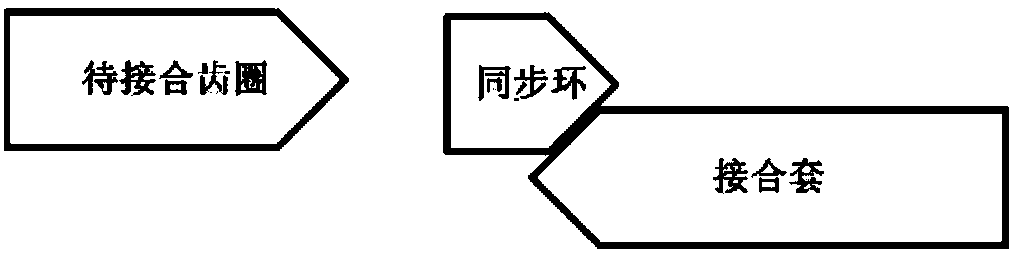

[0062] like Figure 1-7 As shown, the analysis of the locking ring synchronizer gearing process can be divided into 7 special position points and 6 stages:

[0063] Stage1: The first free travel of the coupling sleeve, from point A to point B in the figure, that is, from the steady-state neutral position point to the synchronization start point;

[0064] The synchronous shift fork drives the adapter sleeve to move axially from point A of the neutral position until the end surface of the adapter sleeve contacts the end surface of the synchronization ring. This stage can be subdivided into two processes according to the change of resistance:

[0065] The adapter sleeve moves axially from point A of the neutral position until the end surface of the slide block contacts with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com