A verification device for a brake test platform

A verification device and platen technology, which can be applied to measurement devices, vehicle testing, and machine/structural component testing, etc., can solve problems such as inconvenience in verification, and achieve the effects of low production cost, convenient use, and simplified verification process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

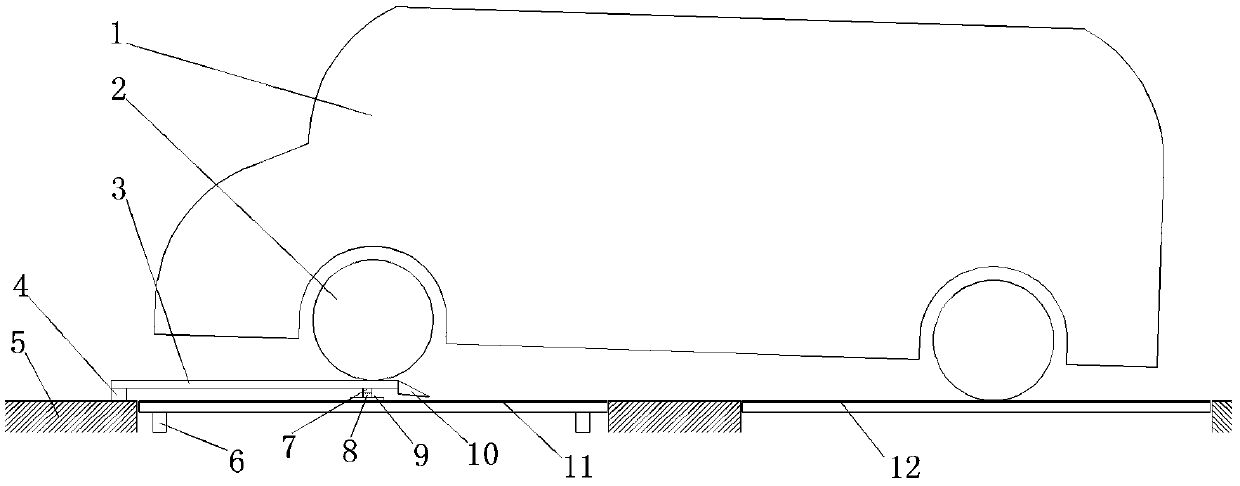

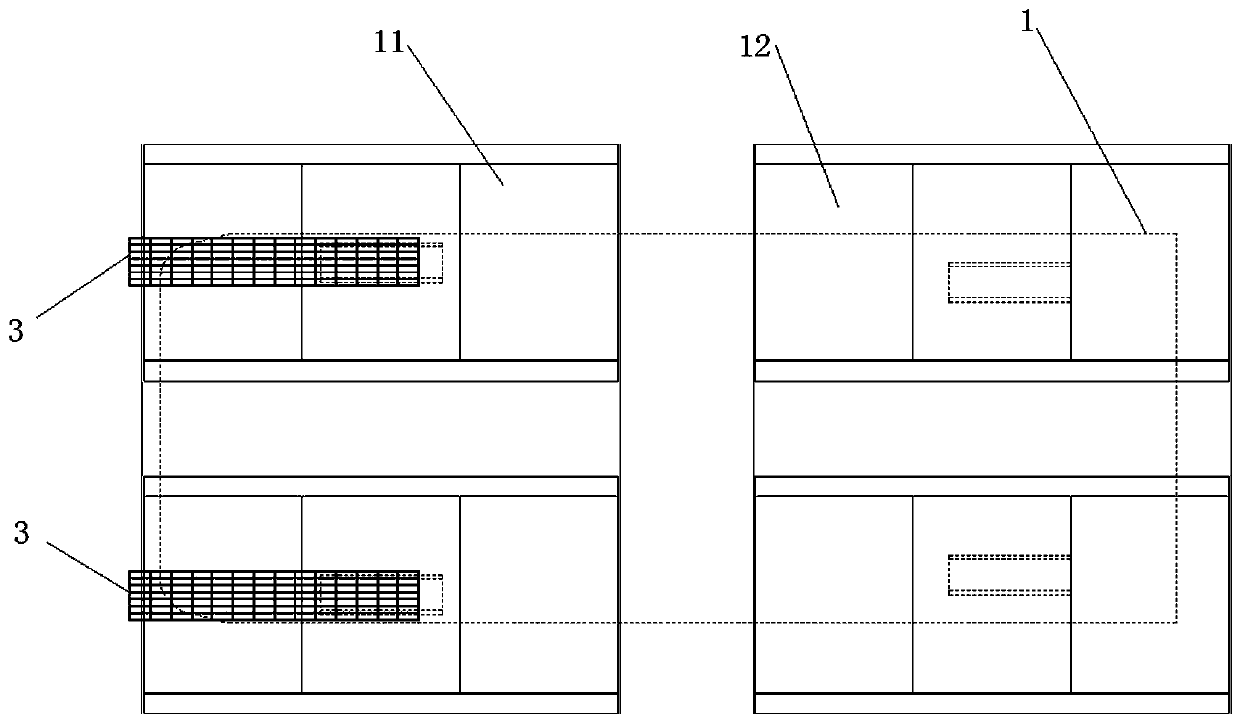

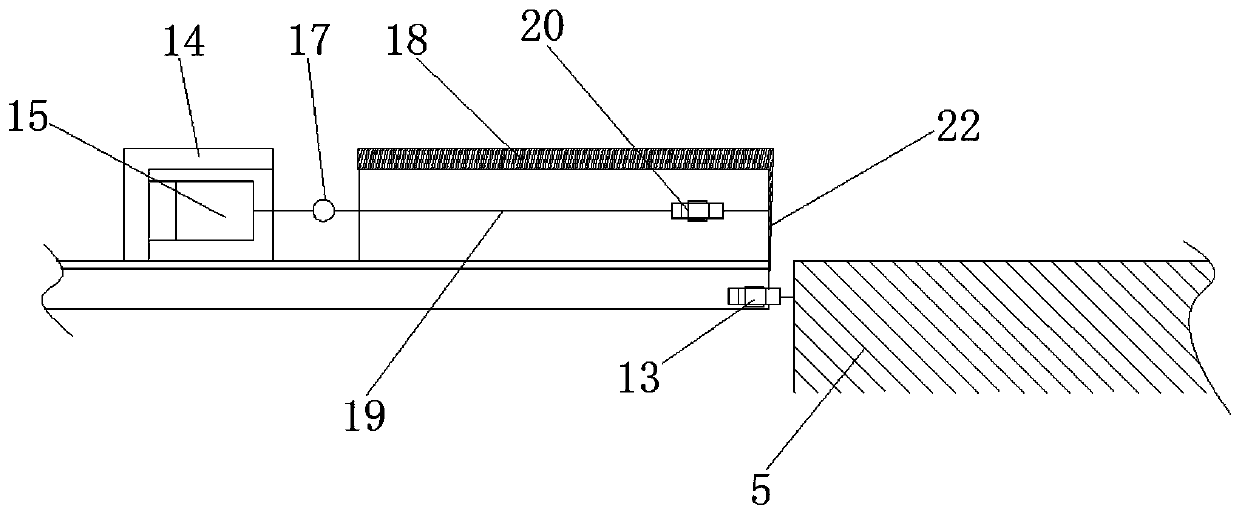

[0014] Before the verification device in the present invention is introduced in detail, first introduce the plate type brake test platform in the prior art, the plate type brake test platform includes a base body 5 and a pair of front wheels 2 for manufacturing a car A front brake bench 11 for dynamic inspection and a pair of rear brake benches 12 for performing brake inspection on the rear wheels of the automobile, two brake benches in the pair of front brake benches are arranged at intervals from left to right The two brake plates in the pair of rear brake plates are arranged at intervals from left to right. The base body can be a metal structure or a concrete structure. A force sensor 13 arranged horizontally is arranged between the base body and the corresponding braking platen. The force sensor is used to detect the braking force borne by the braking platen. A vertically arranged load cell 6 is arranged between the brake plates, and the load cell is used to detect the axl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com