Intelligent detection equipment for chemical fiber silk ingot appearance defects

Appearance defect, intelligent detection technology, applied in the direction of optical test defects/defects, etc., can solve problems such as broken wires, affecting downstream production links, and huge equipment resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

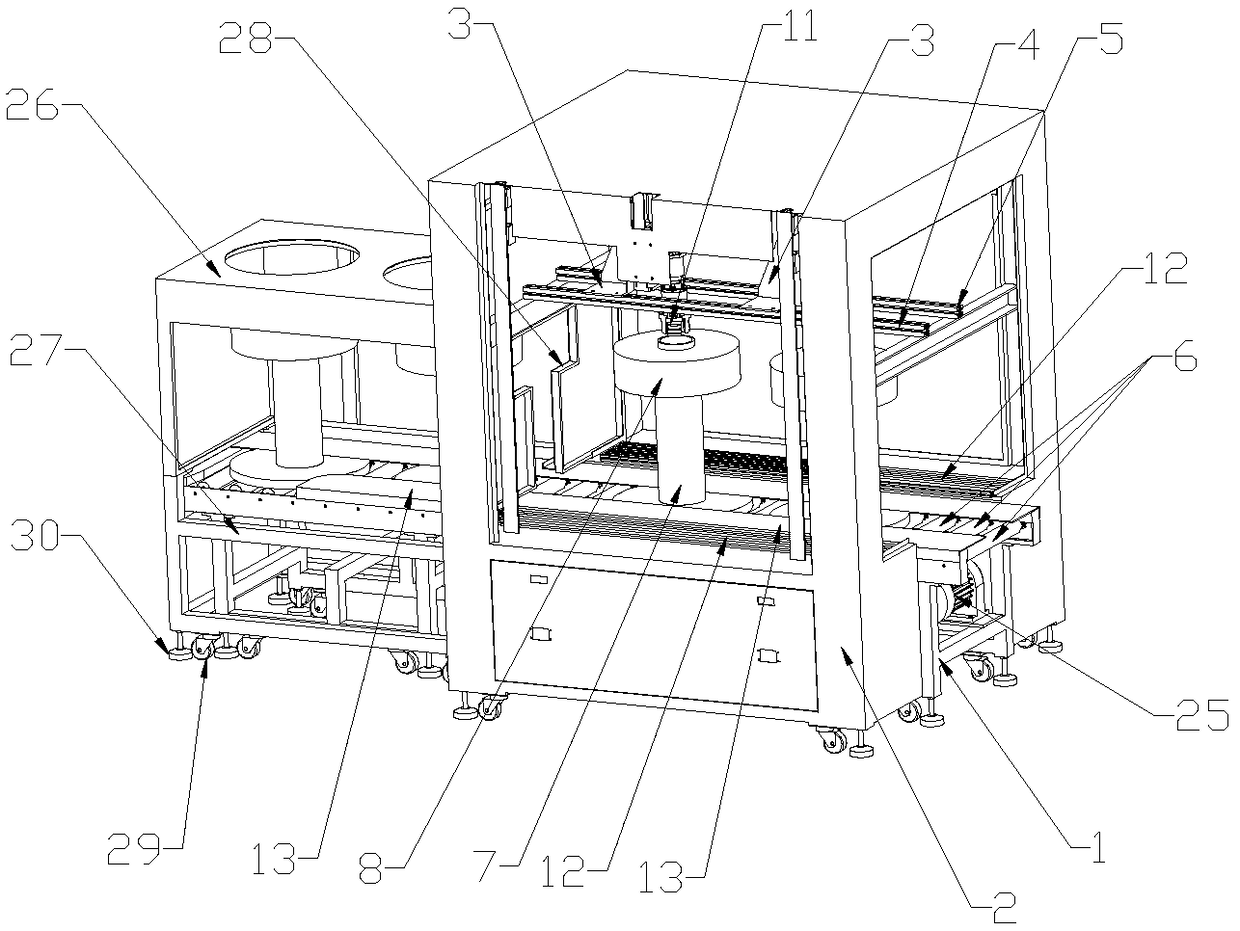

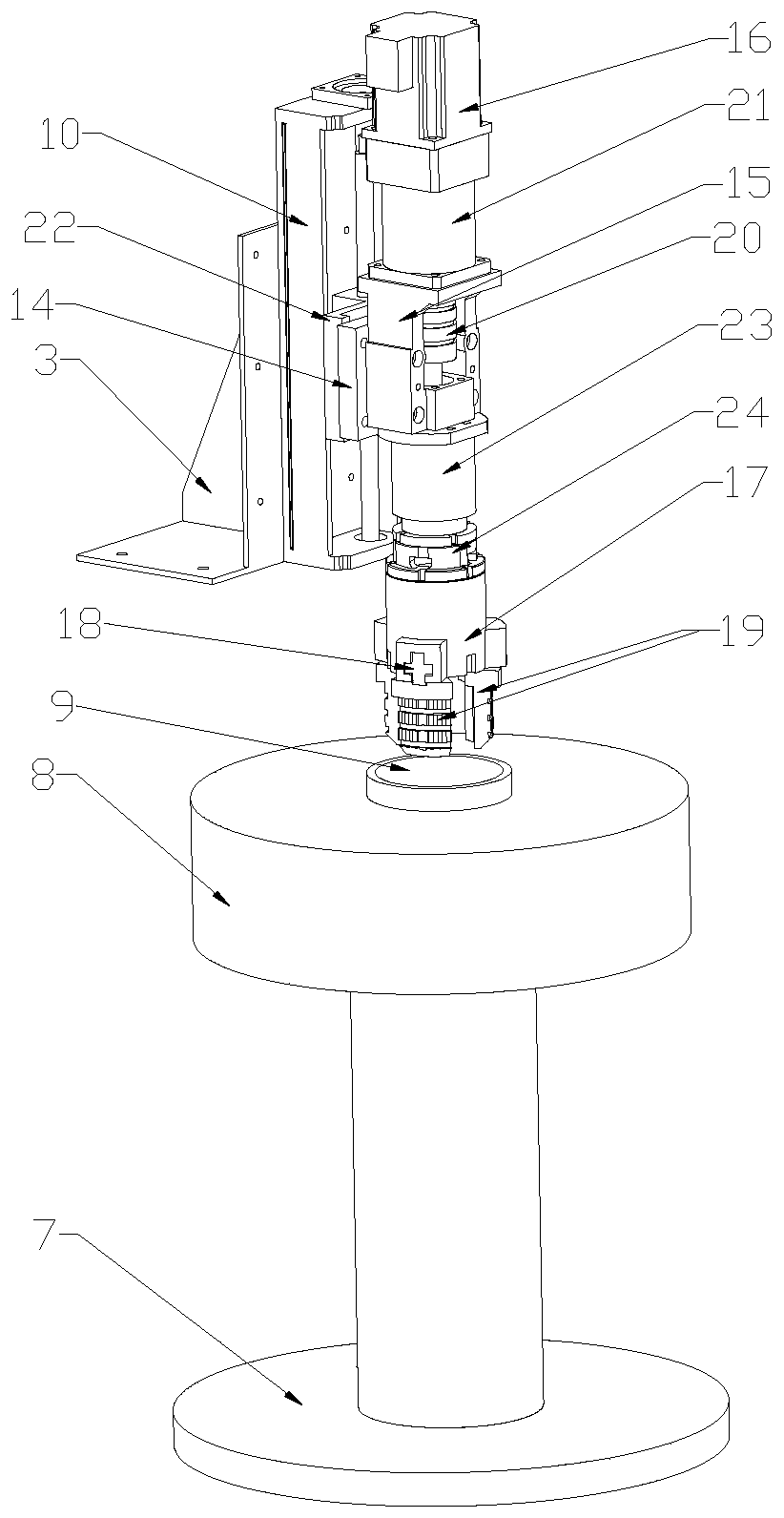

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0021] Such as Figure 1 to Figure 2 As shown, in this embodiment, an intelligent detection device for appearance defects of chemical fiber ingots includes a working chassis 1, a working cover 2, a lifting main seat 3, a first crossbeam 4 and a second crossbeam 5, and the first crossbeam 4 and the second beam 5 are parallel to each other, and both the first beam 4 and the second beam 5 are located above the working cover 2, and the working cover 2 is set on the outside of the working chassis 1 , the working underframe 1 is provided with several rollers 6 for conveying, on which a turntable 7 is placed, and the upper end of the turntable 7 is fixed with a wire spindle reel 8, and on the wire spindle reel 8 Line holes 9 arranged along the vertical direction are provided, and the two sides of the lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com