Filter net automatic renewal device and air conditioner with same

An automatic update and filter technology, applied in home appliances, space heating and ventilation details, household heating, etc., can solve the problems of inconvenient cleaning and replacement, easy accumulation of dust, avoid secondary pollution, and have a high degree of automation. , The effect of prolonging the manual installation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

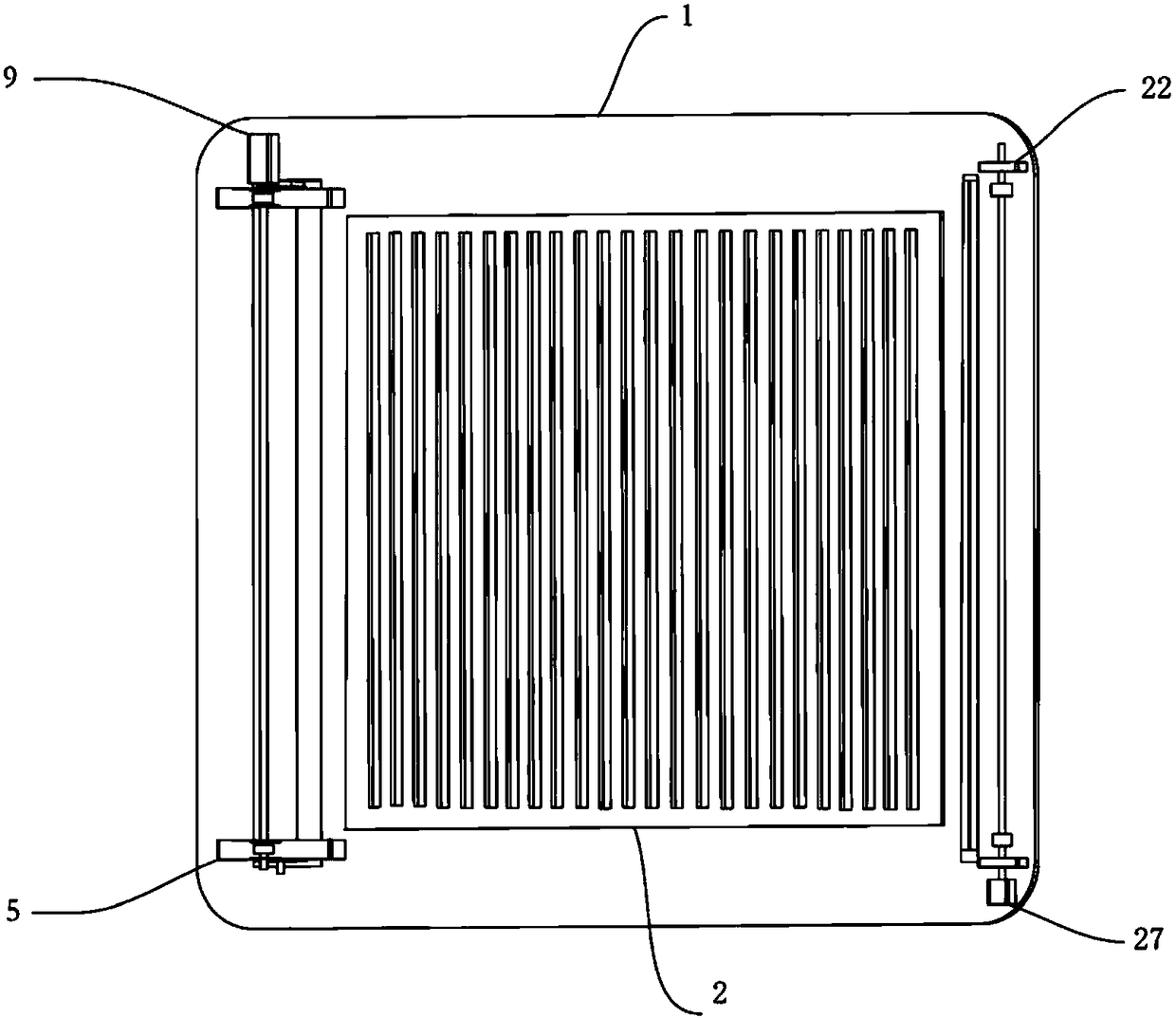

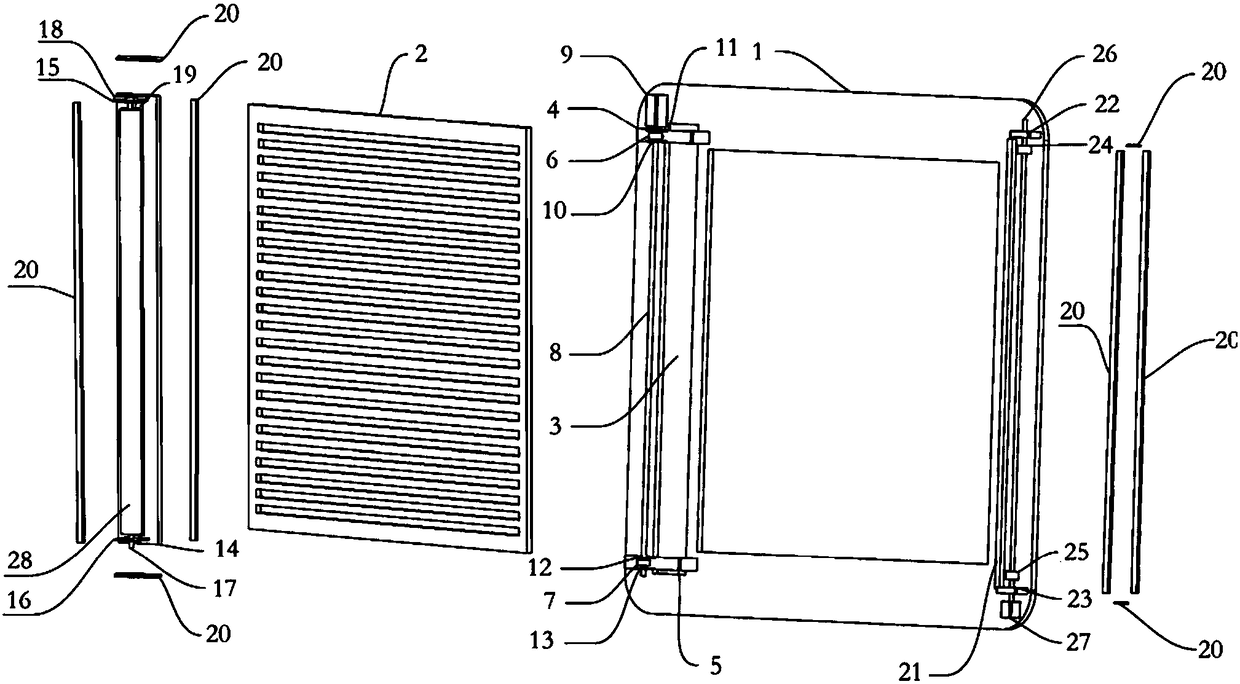

[0032] The filter screen automatic update device is mainly composed of the air intake grille frame 1, the filter screen lifting assembly arranged on the frame, the filter screen recovery assembly, the filter screen release assembly, and the air intake grille 2, such as figure 1 shown. Its exploded view and the names of each part are as follows: figure 2 shown.

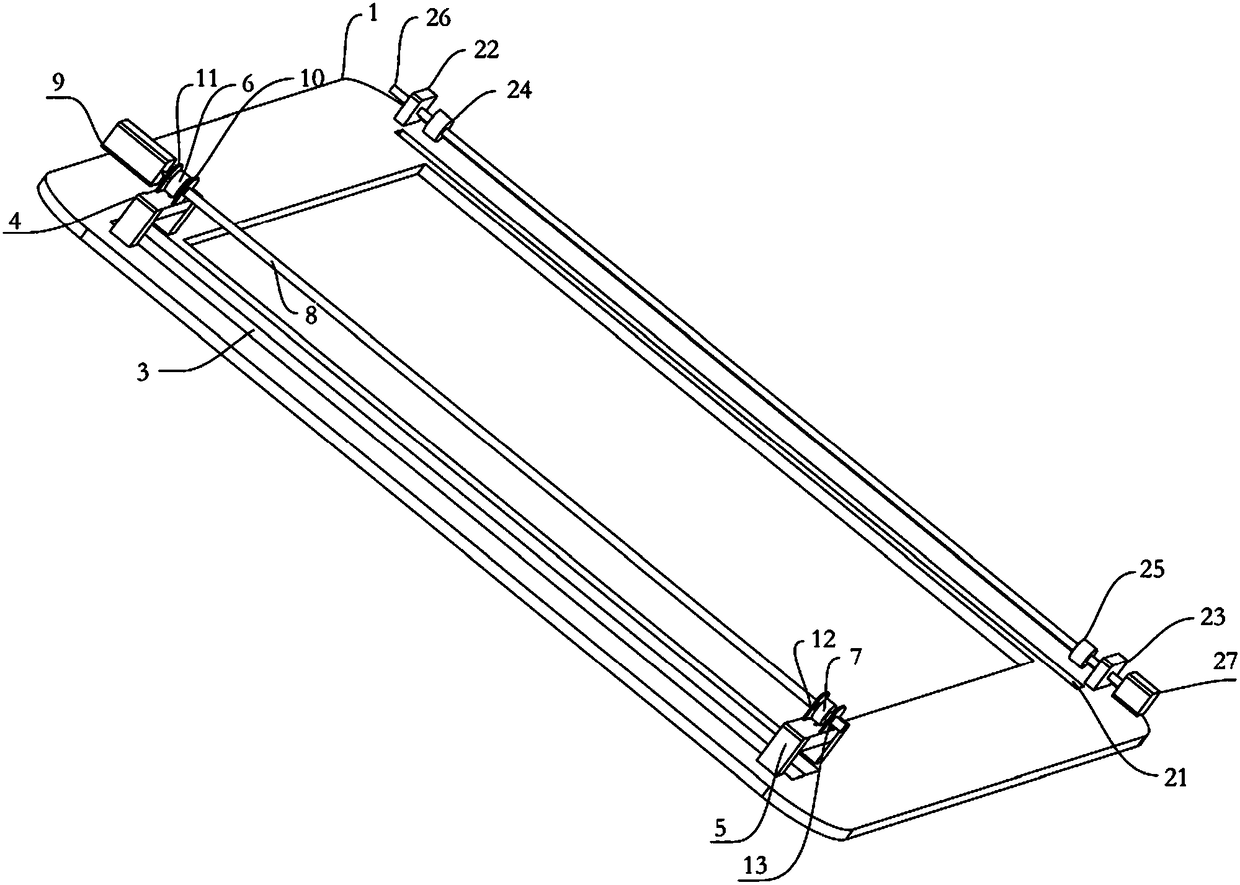

[0033] Wherein, one side of the air intake grille frame is provided with a filter lifting assembly, and the opposite side is provided with a filter releasing assembly, such as image 3 .

[0034]There is a card position 3 for placing the filter net recovery component on the side frame of the filter net lifting component, and the filter net lifting component is erected on the card position, which is used for transmission connection with the filter net recovery component, and controls the lifting of the filter net recovery component.

[0035] The filter lifting assembly includes a first assembly support 4, a second a...

Embodiment 2

[0042] The filter screen automatic updating device includes: an air intake grille frame, an air intake grille, a filter screen lift assembly and a filter screen recovery assembly. On both sides of the hollow area of the frame of the air intake grille, there are respectively provided a first clamping position 29 and a second clamping position 30 for placing a filter recovery component, and each clamping position is respectively provided with a filter lifting component.

[0043] The filter screen lifting assembly includes a first assembly bracket, a second assembly bracket, a first roller, a second roller, a first rotating shaft, a first micro motor and a pull wire. The first component bracket and the second component bracket are erected at both ends of the clamping position respectively, the first and second lifting component shaft brackets are arranged above the first component bracket, and the third and fourth lifting component shafts are arranged above the first component b...

Embodiment 3

[0047] A ceiling-mounted air conditioner includes the filter screen automatic updating device of embodiment 1 or 2. In addition, the air conditioner also includes a filter detection device and an update control system. The filter detection device is used to detect the parameter change of the filter, and the filter detection device includes one or a combination of photoelectric sensors, ultrasonic sensors, electromagnetic sensors, and motion sensors.

[0048] The update control system is used to control the rotation of the micro-motor according to the obtained parameter change of the filter screen to control the replacement of the filter screen and the lifting of the filter screen recovery assembly.

[0049] When it is detected that the performance values such as color change, light transmittance change, or air intake change of the filter reach the set value, the recovery and release components are controlled to be linked to complete the update of the filter. The process req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com