Length compensation method of saw cutting of section bars through cutting machine

A technology of length compensation and cutting machine tools, which is applied in computer control, instruments, simulators, etc., can solve the problems of limitations, high requirements of machine tools and CNC systems, optimize cutting force errors, improve machining accuracy and efficiency, and improve machining accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

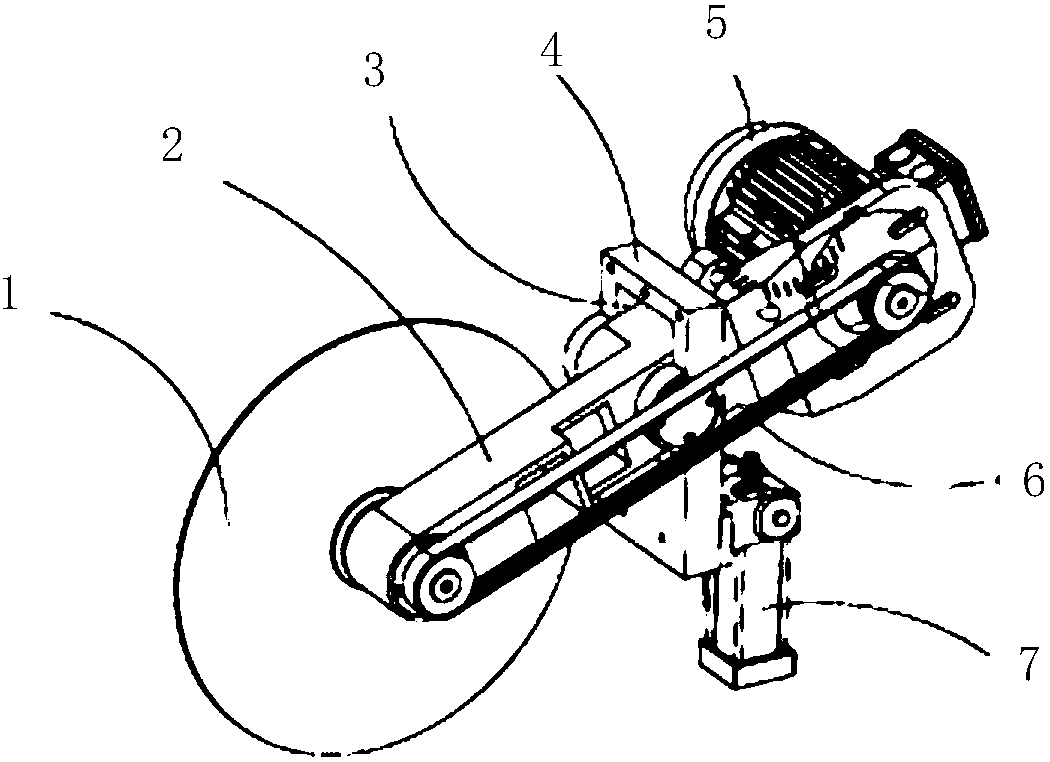

[0048] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

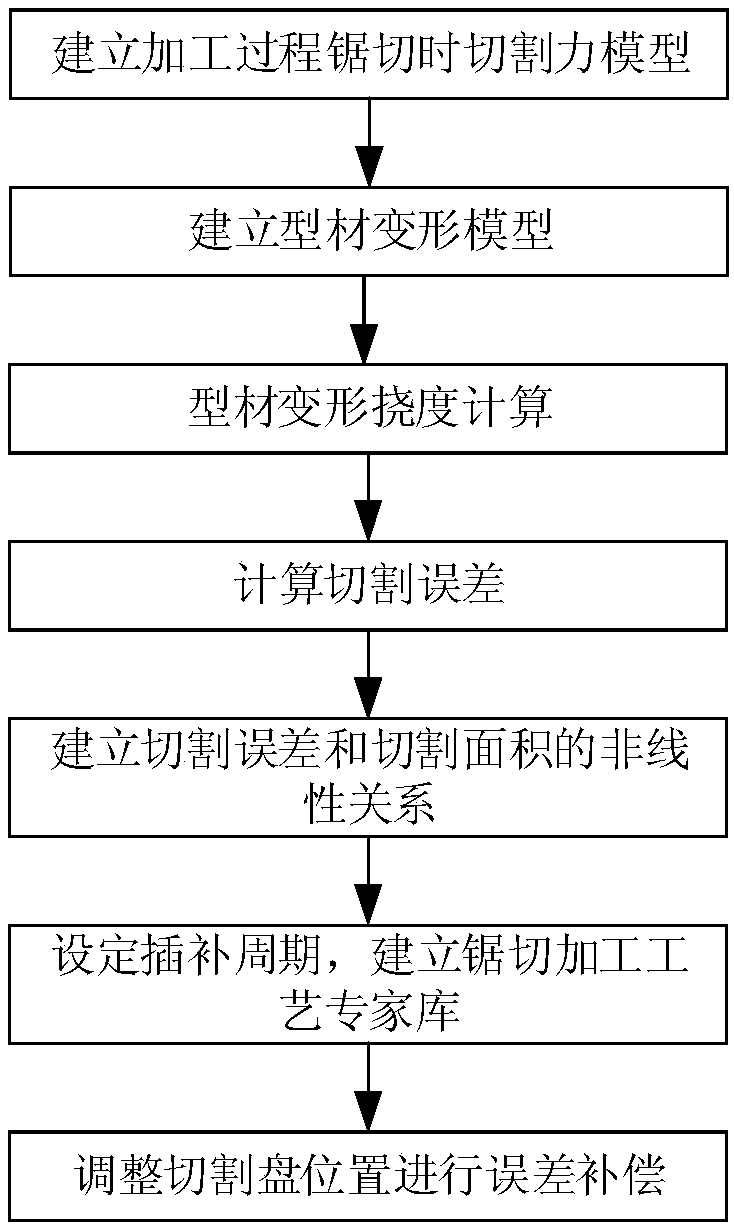

[0049] As attached Figure 1-3 As shown, the present invention discloses a length compensation method for sawing profiles of a cutting machine tool, which includes the following steps:

[0050] S1, establish a cutting force model during sawing in the machining process.

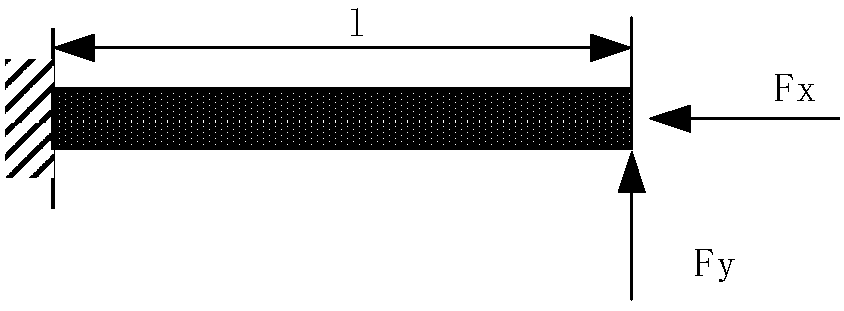

[0051] S2, establish an aluminum profile deformation model.

[0052] S3, set the interpolation cycle, and establish a sawing process expert database based on the known information of the aluminum profile and the nonlinear relationship between the cutting error and the cutting area. The corresponding relationship between cutting error and cutting area is nonlinear, that is, the larger the cutting area, the smaller the cutting error.

[0053] S4: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com