Intelligent leather flattening device

A leather and equipment technology, applied in the field of intelligent flattening leather equipment, can solve problems such as inconvenient operation, lack of monitoring equipment, and poor flattening effect, so as to save production costs and ensure the effect of flattening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

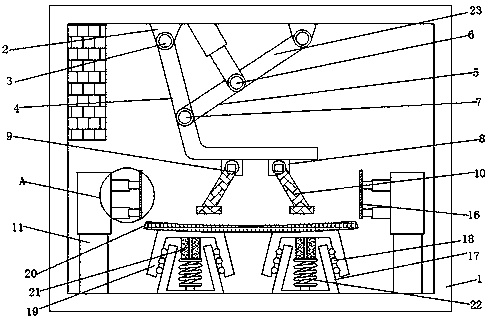

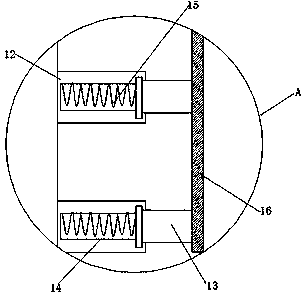

[0019] Example: refer to Figure 1-2 , a kind of intelligent flattening leather equipment, first place the leather to be flattened on the placement plate 20 at the upper end of the casing 1, the bottom side wall of the casing 1 is equipped with an electric telescopic rod 11, and one end side of the electric telescopic rod 11 The wall screw is fixed with a placement block 12, and the side wall at one end of the placement block 12 is movably connected with an elastic rod 13, and the bottom side wall of the elastic rod 13 is glued to a spring 15, and the other end of the spring 15 is glued to the bottom of the support rod 14 The inner wall, and the support rod 14 is located inside the placement block 12, the other end of the elastic rod 13 is welded with a fixed plate 16, and then the electric telescopic rod 11 works, and the electric telescopic rod 11 is stretched to the longest length, and then the electric telescopic rod 11 is away from One side of the bottom end of the housin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com