Elastic gas sealing gasket and sealing method for gas sealing of common screw thread oil pipe

A gas-tight and air-tight technology, which is applied in the directions of sealing/isolation, earthwork drilling, wellbore/well components, etc., can solve problems such as sealing at unfavorable threads, adverse effects on the sealing effect at the box, and erosion, etc., to achieve Good sealing effect, stable and reliable sealing effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

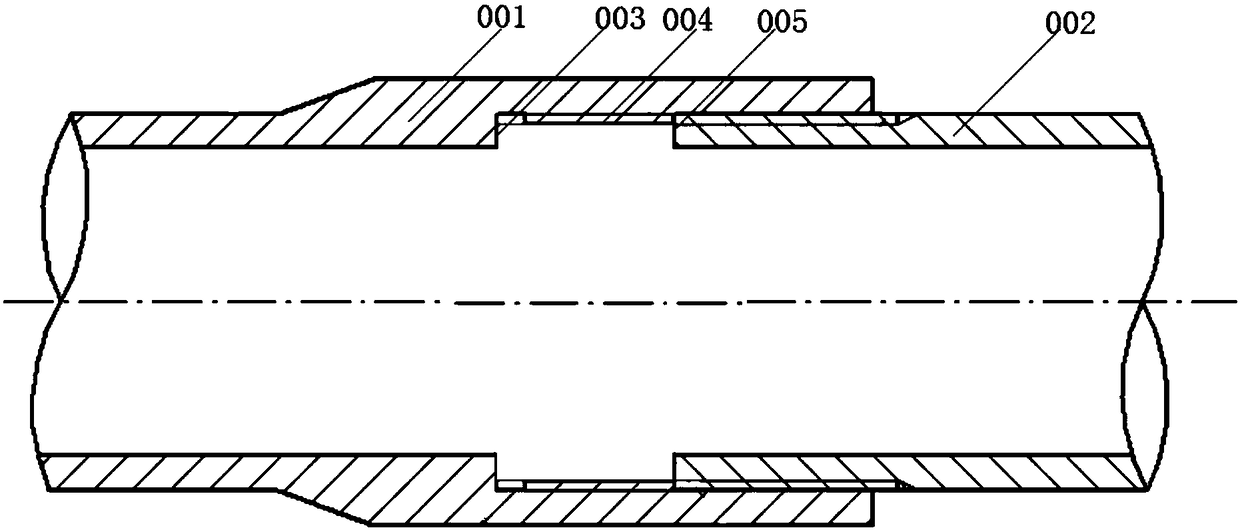

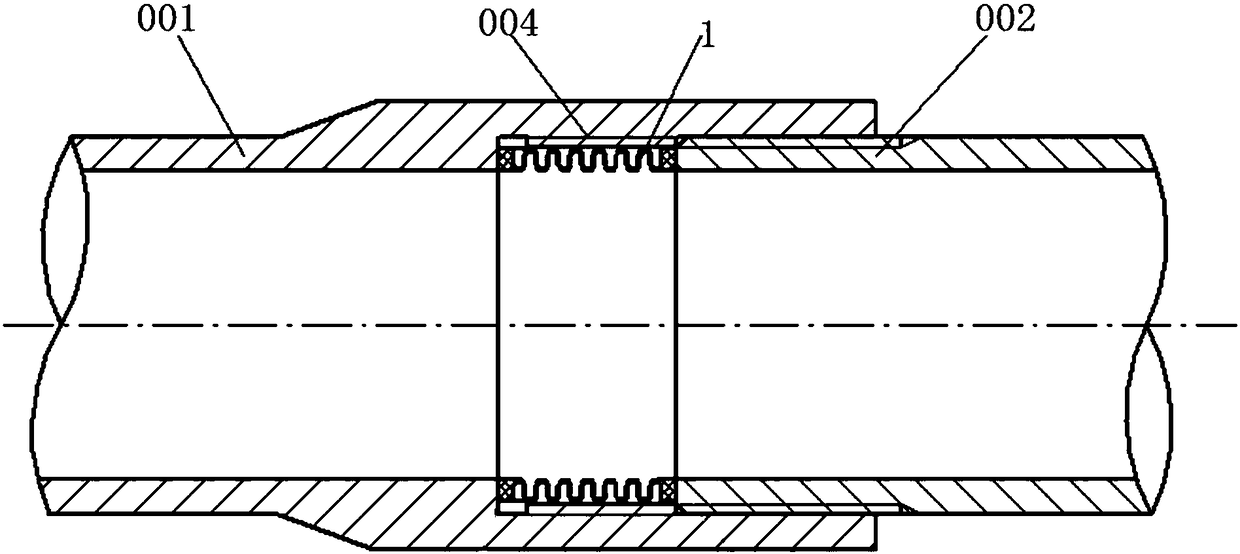

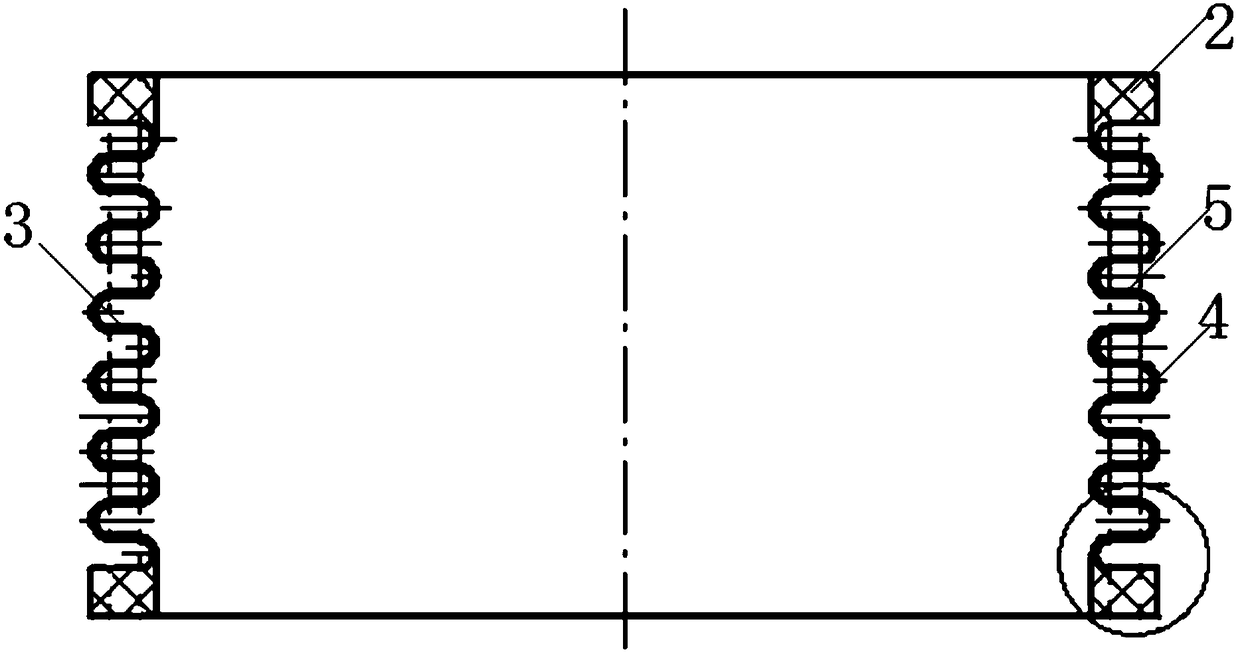

[0085] According to the elastic gas sealing gasket for gas sealing of common thread oil pipes provided by the present invention, the gasket includes an elastic member 1 installed between the end face 005 of the male buckle and the end face 003 of the female buckle, and the elastic member 1 includes two ends on both sides The end 2 and the side wall 3 between the two ends 2; the longitudinal section of the side wall 3 is corrugated; the corrugation includes alternately connected arc segments 4 and straight segments 5;

[0086] The shapes and sizes of the plurality of arc segments 4 are the same. The radius size of the inner circle of the arc segment 4 is 1mm; the radius size of the outer circle of the arc segment 4 is 1.3mm, that is, the thickness dimension of the arc segment is 0.3mm. ;

[0087] The dimensions of the plurality of straight segments 5 are the same, the lengths of the plurality of straight segments 5 are all 1.9 mm, and the thickness of the straight segments 5 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius size | aaaaa | aaaaa |

| Radius size | aaaaa | aaaaa |

| Length value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com