Conical sealing cover

A cone and truncated cone type technology, which is applied in the field of cone capping, can solve the problems of waste, glue leakage, and unsatisfactory sealing of the nozzle, and achieve the effect of good sealing effect and enhanced sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

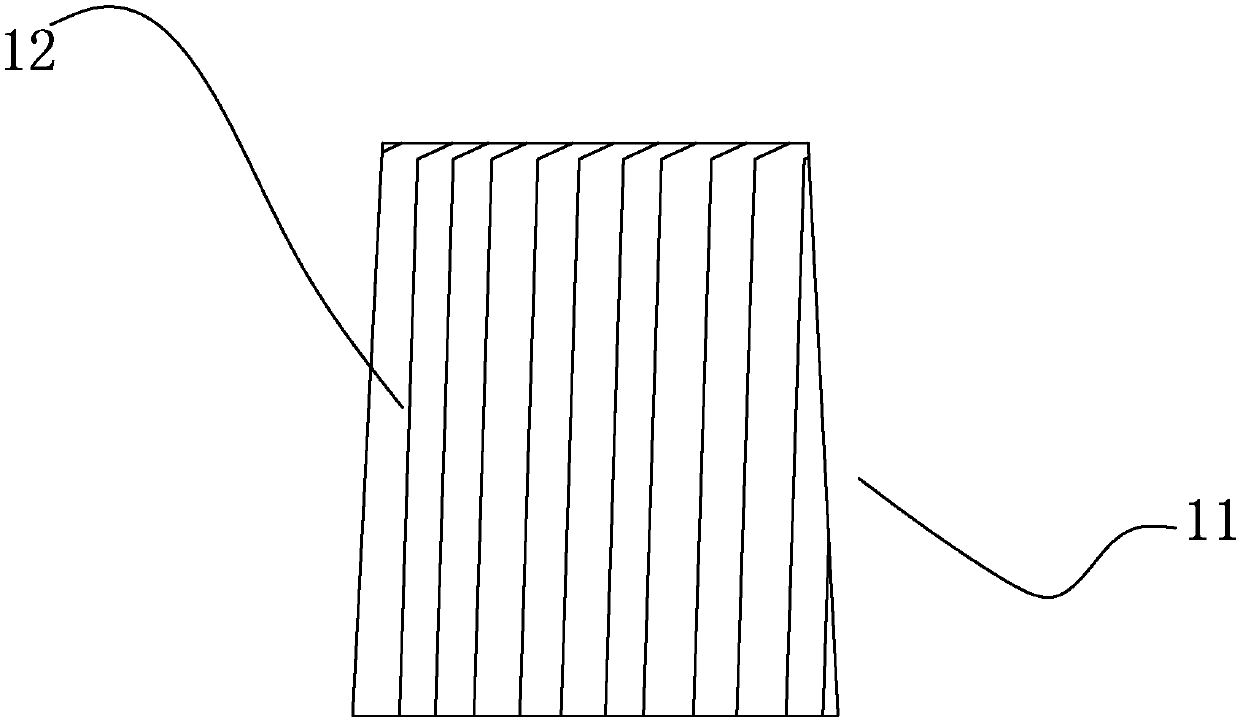

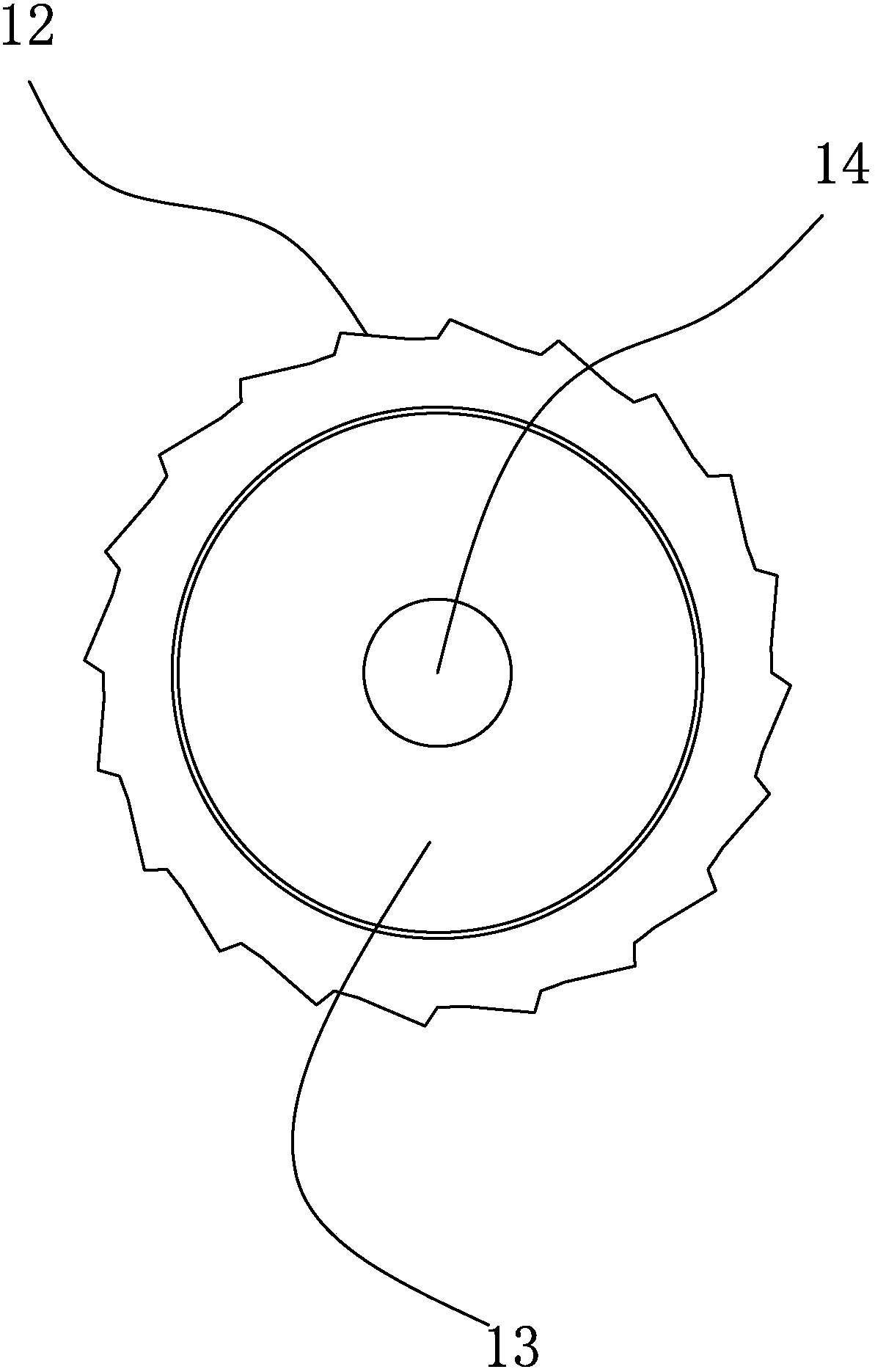

[0018] refer to Figure 1~2 , a conical closure, including a cover body 11, the cover body 11 is in the shape of a truncated cone, the inner side of the cover body 11 is provided with an internal thread for connecting the nozzle, and the bottom center of the cover body 11 is provided with a sealing cylinder for plugging into the nozzle 14. The sealing cylinder 14 is covered with a sealing gasket 13 .

[0019] While the cover 11 seals the nozzle through the internal thread, the sealing cylinder 14 is blocked into the nozzle, and the sealing cylinder 14 is sealed into the nozzle. The cover 11 and the sealing cylinder 14 seal the nozzle from the outside and inside respectively, and the sealing effect Well, to prevent glue leakage and affect the quality of the glue reuse, the sealing gasket 13 is used to strengthen the seal.

[0020] The sealing gasket 13 is colored, and it can be checked very intuitively whether the sealing cylinder 14 is covered with the sealing gasket 13, so a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com