Lens raw material storage tank

A technology for storage tanks and raw materials, which is applied in the direction of packaging, closing, packaging, etc. under special gas conditions. It can solve the problems of affecting pouring, rough sealing, and unstable air pressure regulation, so as to avoid poor sealing and enhance sealing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

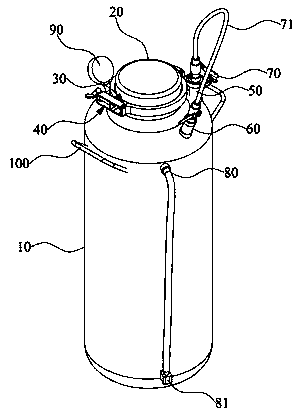

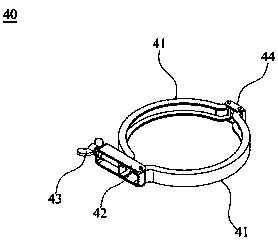

[0020] Please refer to figure 1 , figure 1 It is a schematic diagram of the lens raw material storage tank of the embodiment of the present application. As shown in the figure, a lens raw material storage tank includes a tank body 10; a tank cover 20 that seals the tank body 10, and the tank cover 20 and the tank body 10 are in contact with each other through a flange portion 30; Component 40, snap-fit component 40 separates or buckles the flange part 30; the discharge port 50 and the feed port 60 are respectively installed on the top of the tank body 10; the discharge port 50 and the feed port 60 can be connected through a one-way valve 70 The hose 71; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com