Liquid burst testing device

A test device, liquid explosion technology, applied in the direction of measuring device, using stable tension/pressure test material strength, instruments, etc., can solve the problems of inconvenient use, liquid leakage, costly materials, etc., to improve the convenience of use performance, prevent liquid leakage, and improve the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

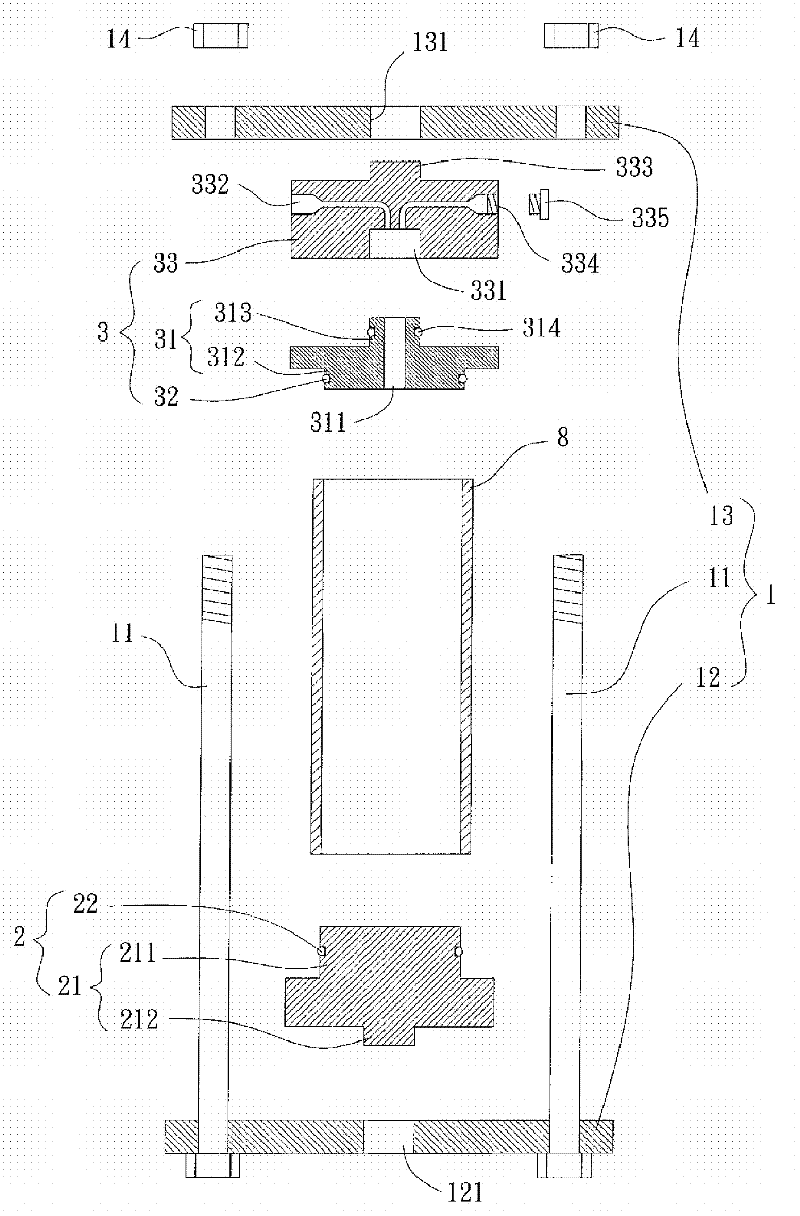

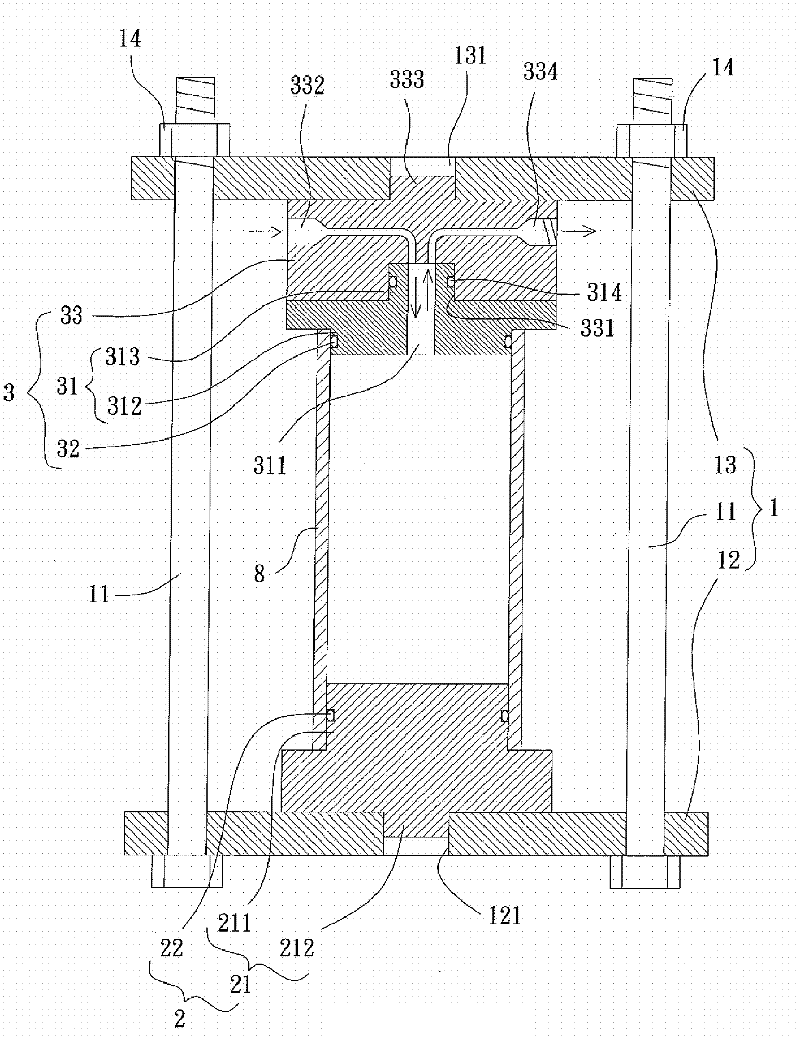

[0031] Such as figure 2 and image 3 As shown, the liquid explosion test device of the preferred embodiment of the present invention comprises a frame body 1, a first sealing assembly 2 and a second sealing assembly 3, and the first sealing assembly 2 and the second sealing assembly 3 are arranged on The frame body 1.

[0032] The frame body 1 is mainly used to carry the first sealing component 2 and the second sealing component 3 . In this embodiment, the frame body 1 includes several pillars 11 , a first splint 12 and a second splint 13 , and the several pillars 11 are arranged between the first splint 12 and the second splint 13 . Wherein, the distance between the first splint 12 and the second splint 13 can be adjusted arbitrarily according to the usage requirements, and the first splint 12 and the second splint 13 can be respectively fixed by several positioning components 14 . In addition, the first clamping plate 12 can also be provided with a first positioning port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com