Changeover valve

A technology of vacuum cleaner and switching valve, which is applied in the field of switching valve to achieve the effect of reducing wear and improving sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

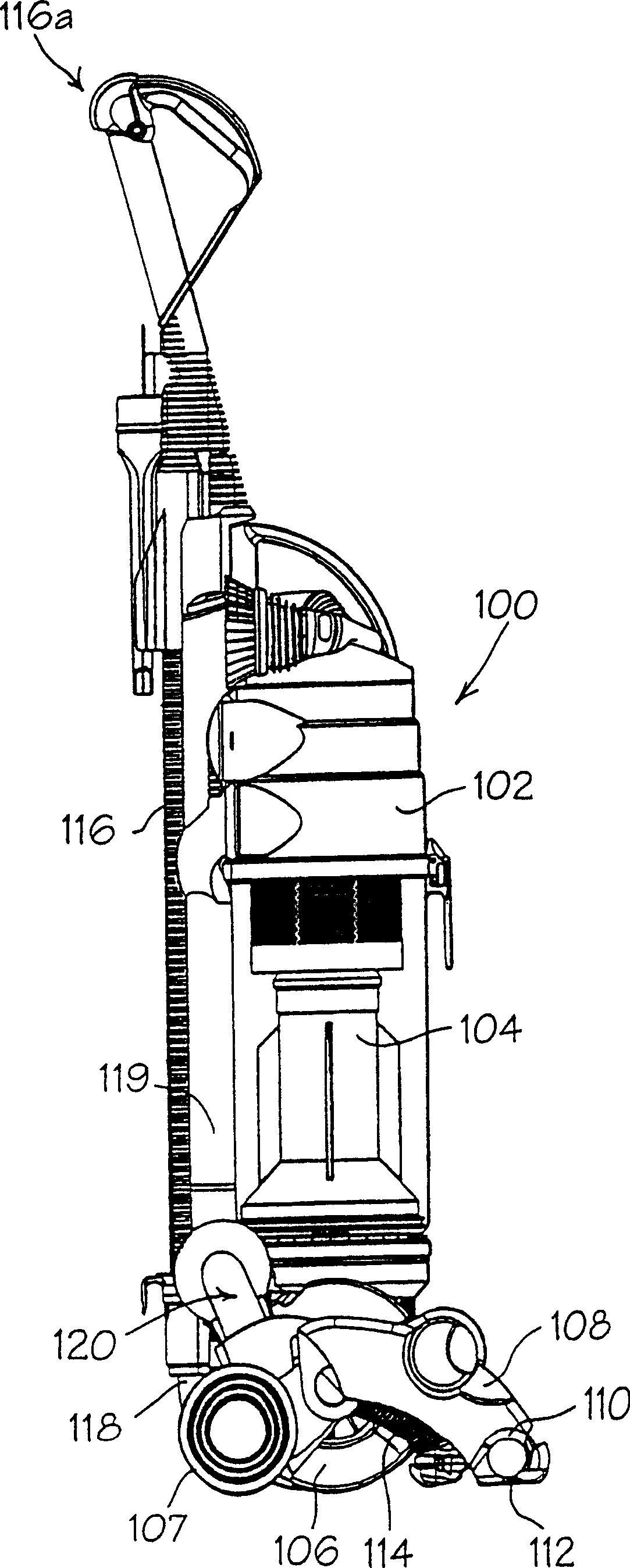

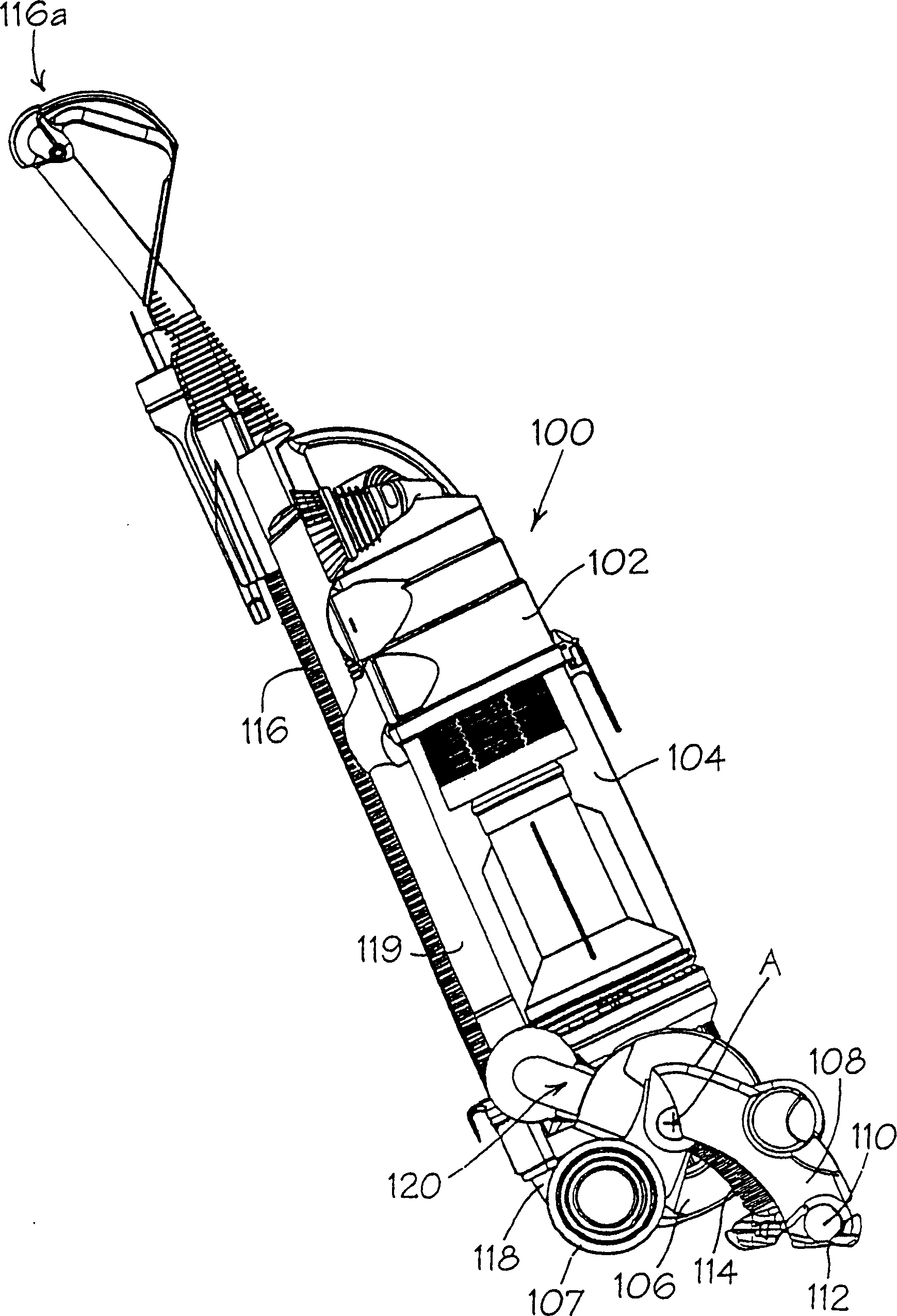

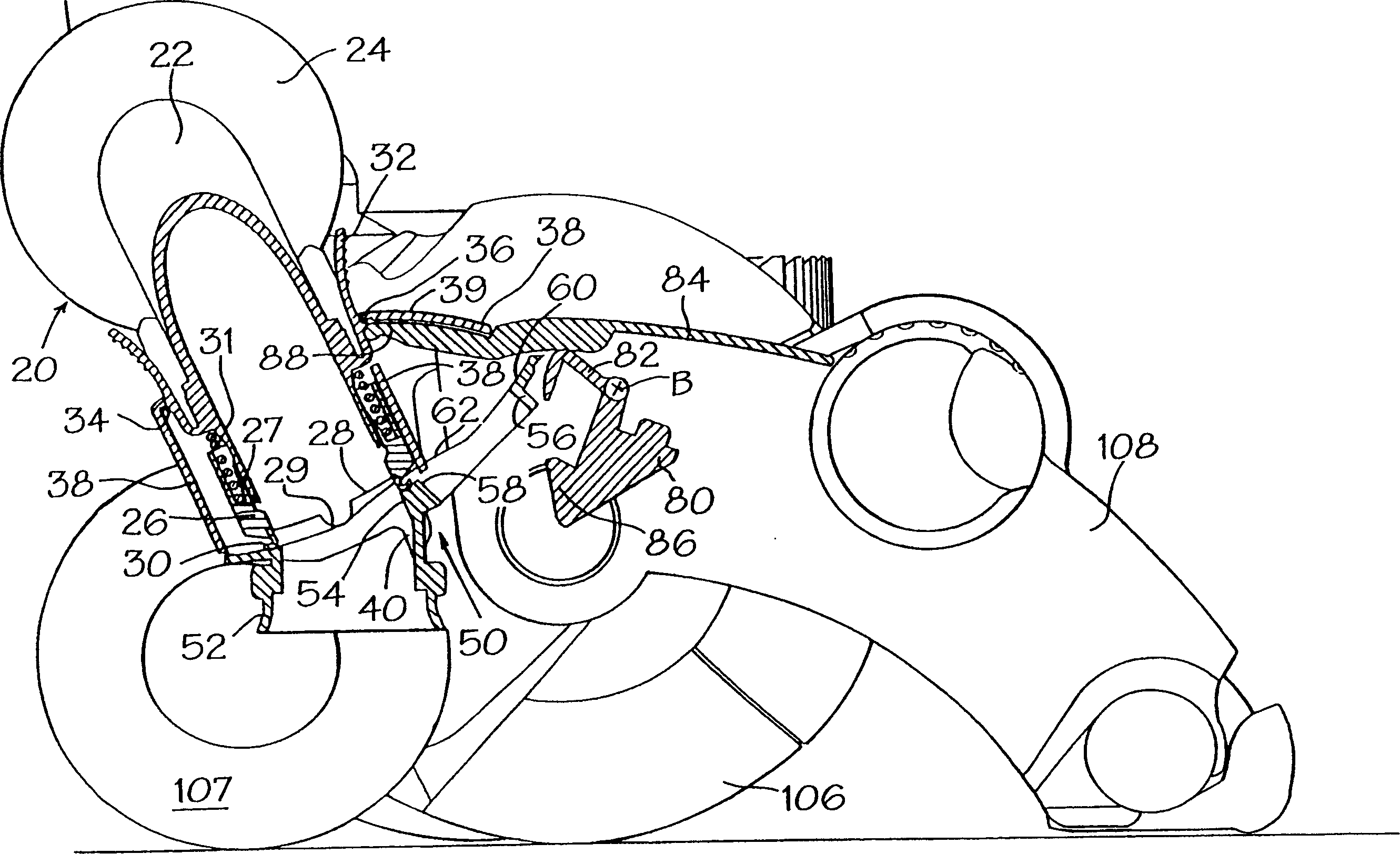

[0020] figure 1 and 2 The entire structure of an upright vacuum cleaner equipped with a switching valve according to the present invention is illustrated. The vacuum cleaner 100 has a main body 102 in which a dust separation mechanism 104 is mounted. In this embodiment the dust separation mechanism 104 is a cyclone dust separation mechanism consisting of two cyclones connected in series. Mechanisms of this type are well known and will not be described any further here, as they have no substantial effect on the invention. The motor housing 106 is located at the lower end of the main body 102 and constitutes a part of the main body 102 . The support wheel 107 is mounted directly on the motor housing 106 . The cleaner head 108 is rotatably mounted on the motor housing 106 about the axis A. As shown in FIG. The cleaner head 108 has a brush housing 110 with an inlet 112 arranged downwards at the front end of the cleaner head 108 . A switch valve 120 is located on the body 102...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com