Adjustable travel detection device

A stroke detection and adjustable technology, which is used in workpiece clamping devices, fluid pressure actuating devices, fluid pressure actuating system testing, etc. compliance issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

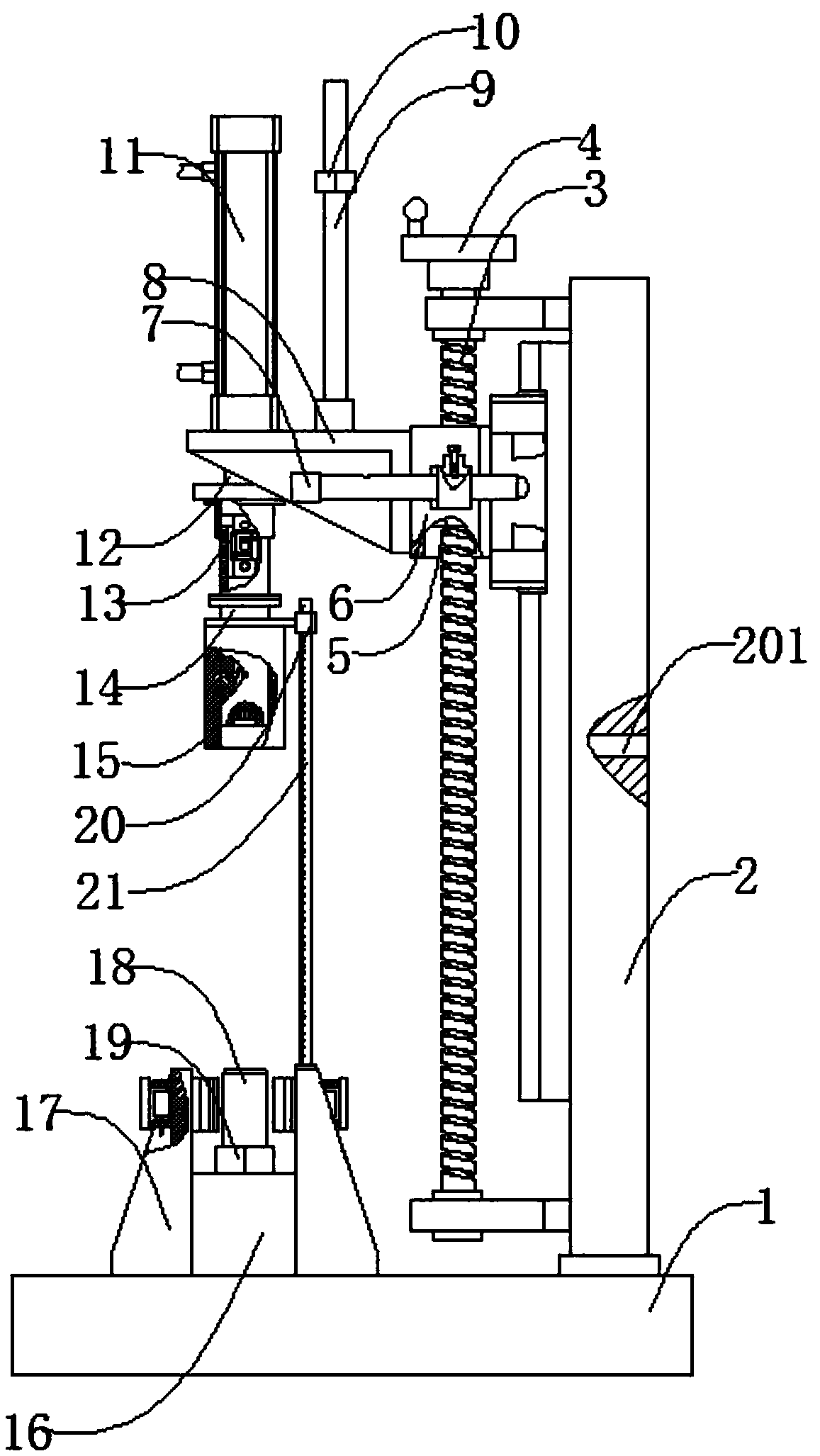

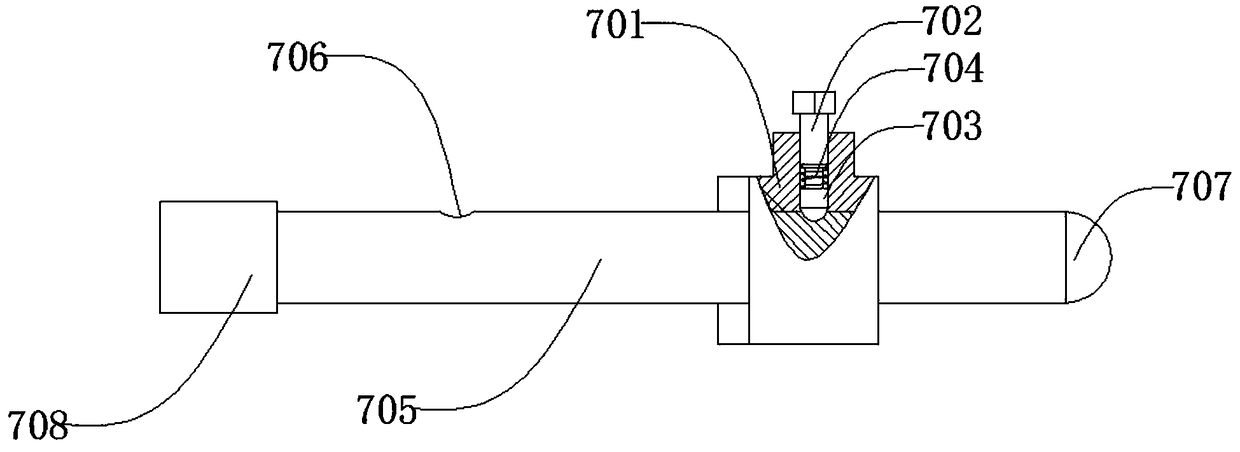

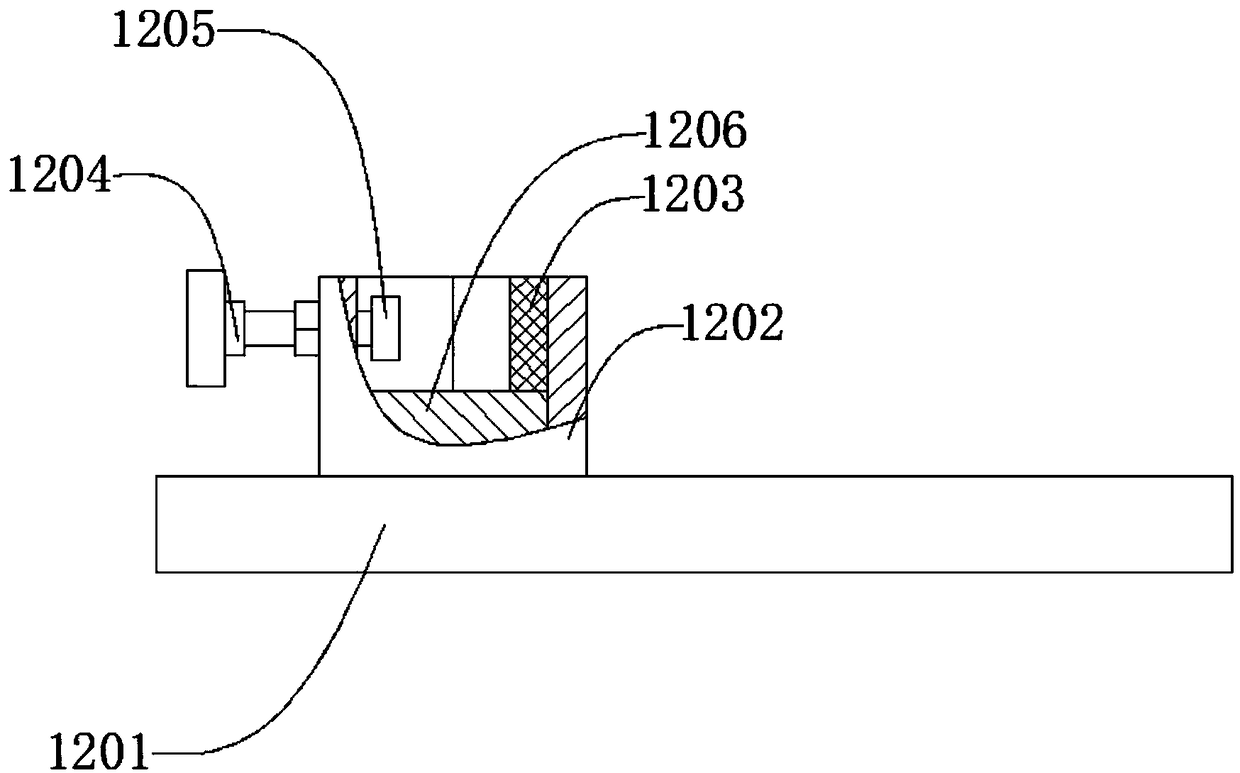

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9As shown, an adjustable stroke detection device includes a base 1, a column 2, a screw 3, a hand wheel 4, a feed nut 5, a sliding seat 6, a locking mechanism 7, a bracket 8, a guide screw 9, a first adjustment nut 10. Oil cylinder to be tested 11, connection assembly 12, pressure detection mechanism 13, limit mechanism 14, calibration sleeve 15, counterweight seat 16, locking mechanism 17, jacking screw 18, second adjustment nut 19, marking block 20, Scale 21, the column 2 is located on the right side of the upper end of the base 1, the column 2 is connected to the base 1 by bolts, the column 2 is also provided with a number of jacks 201, and the jacks 201 run through the column 2, The screw 3 is located on the left side of the column 2, the screw 3 is connected to the column 2 in rotation, the hand wheel 4 is located at the top of the screw 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com