High-power rectifier device and DC pole-changing system

A rectifier, high-power technology, applied in the direction of converting irreversible AC power input to DC power output, etc., can solve the problems of arcing, overheating of contact elements, short life, etc., and achieve extended service life, reliable operation, and heat loss. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

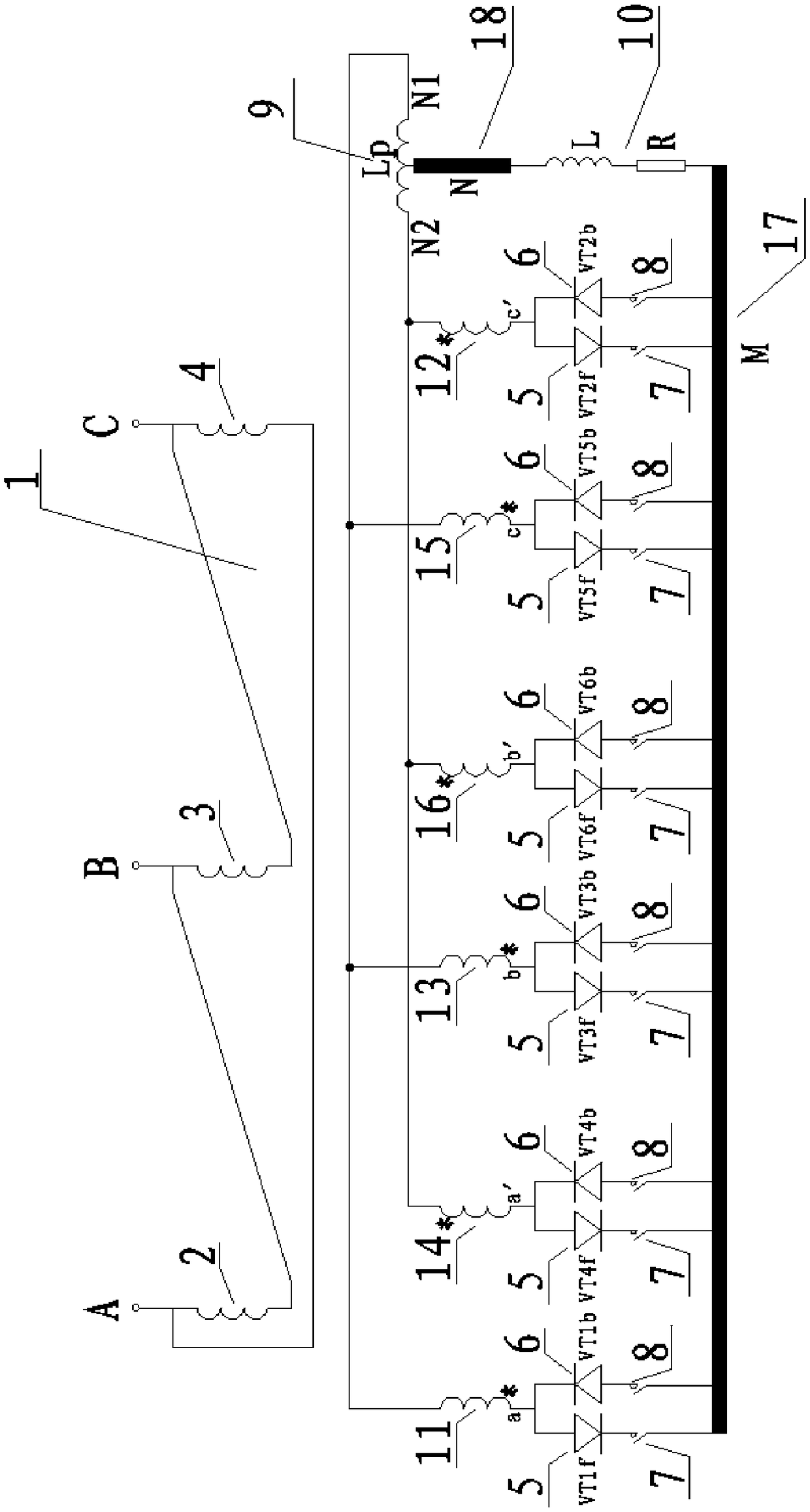

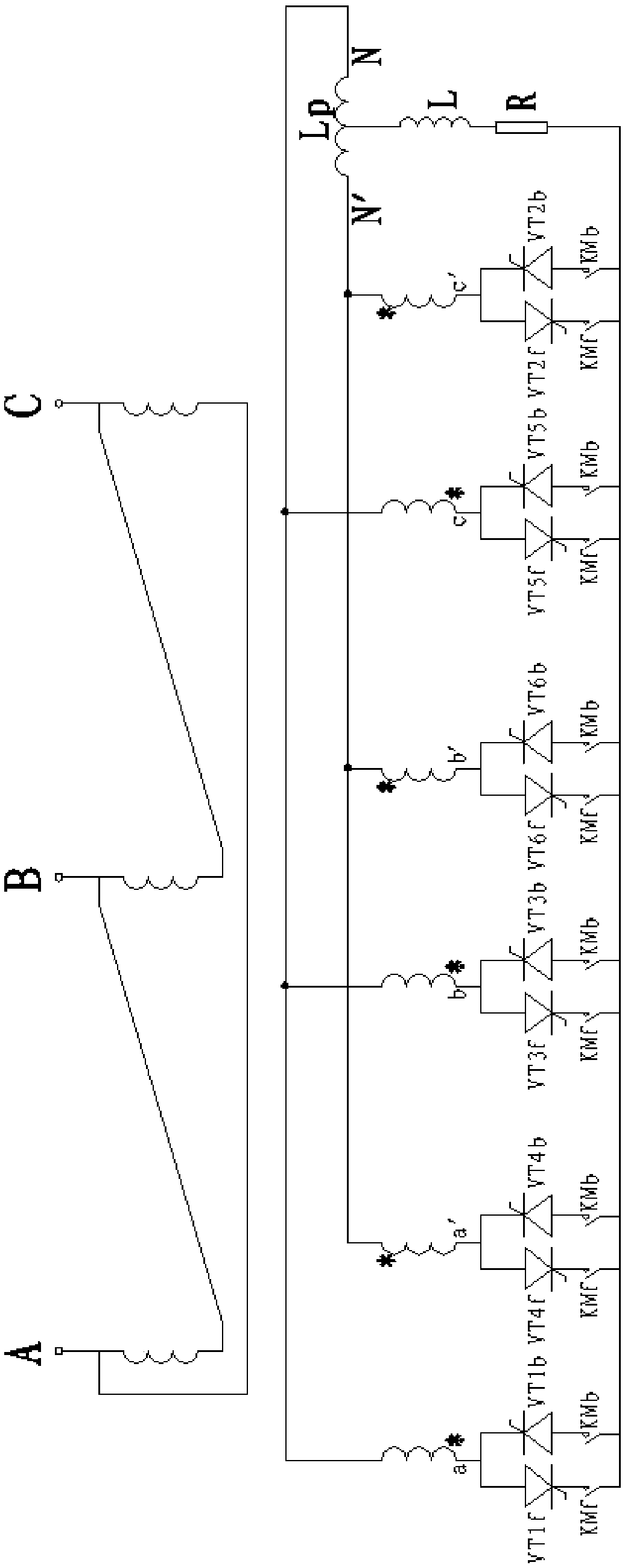

[0022] as attached figure 1 As shown in the rectification circuit section in , a high-power rectification device includes rectification diodes and switching switches. The rectification diodes are divided into two groups, one group is a forward diode group, and the other group is a reverse diode group. Each Each rectifier diode is connected in series with a switching switch, and the switching on and off of the rectifying diode branch is controlled by the switching on and off of the switching switch. Further, the switching switches in which the diodes in each group of forward and reverse diode groups are connected in series one by one form a group of simultaneously controlled vacuum contactor groups. Further, the two groups of vacuum contactors corresponding to the forward and reverse diode groups The contactor groups are interlocked through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com