Resonant post welding spot height calibration device

A calibration device and resonant column technology, applied in the field of resonant column solder joint height calibration device, can solve the problems of inability to scribe, affect the appearance of the resonant column, inaccurate scribe, etc., and achieve improved appearance and performance, convenient debugging and installation, and reduced cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

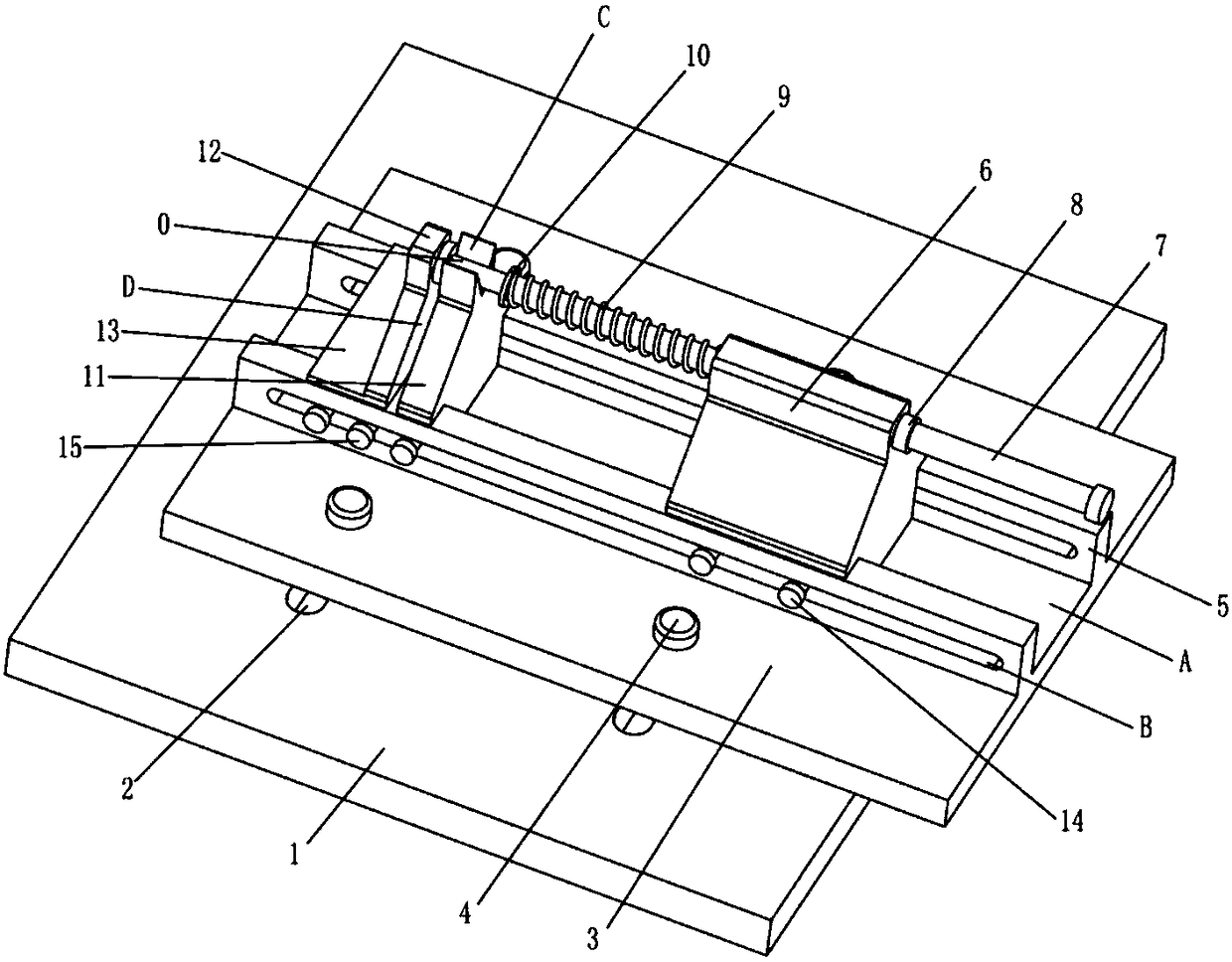

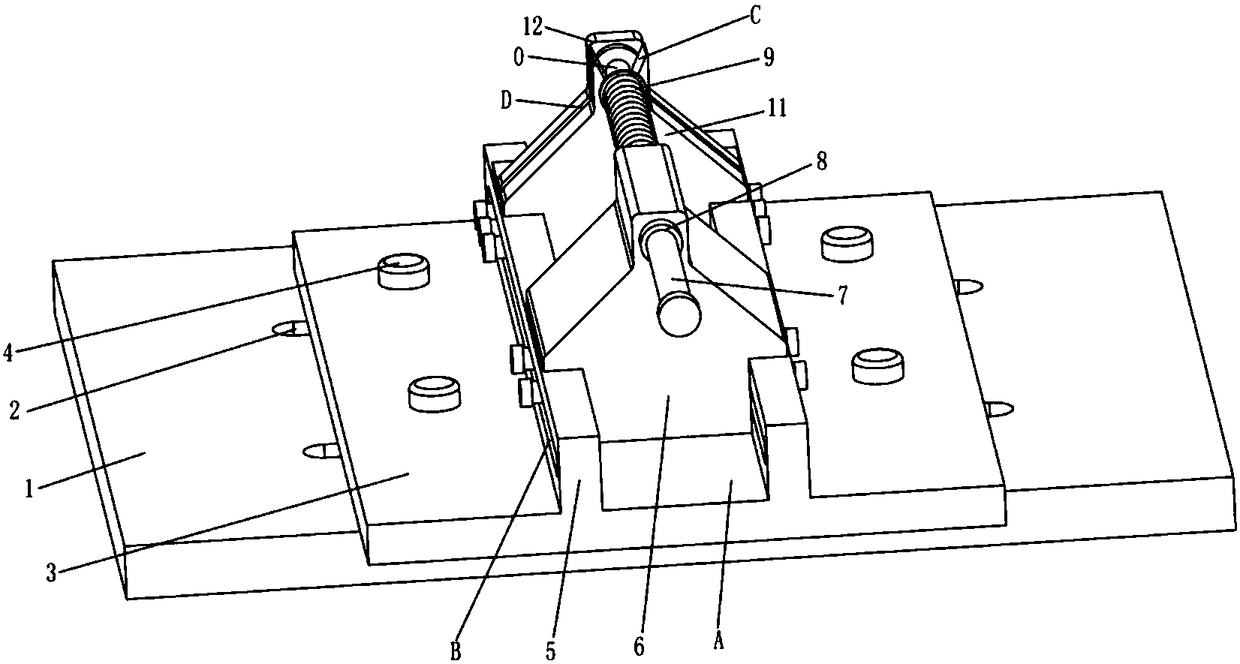

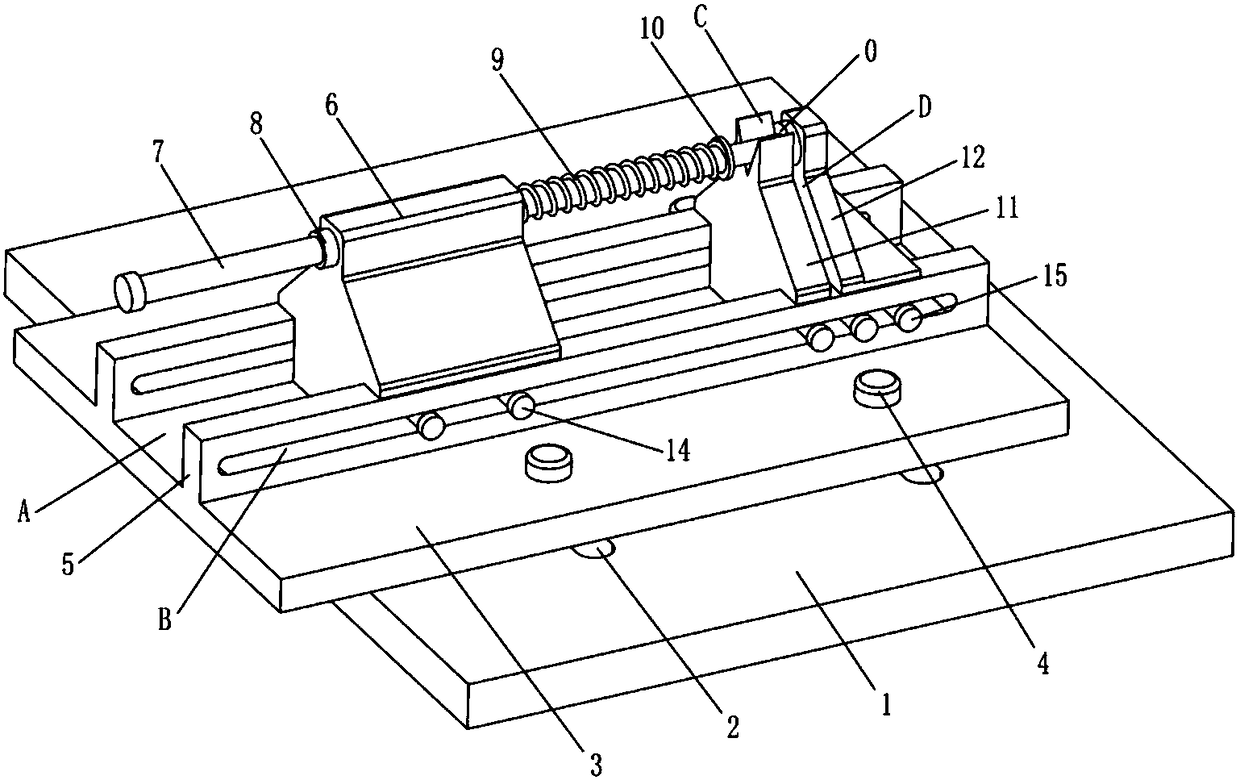

[0025] The present invention will be further described below in conjunction with accompanying drawing:

[0026] Such as Figure 1 to Figure 4 As shown, the technical scheme adopted by the present invention is as follows: a device for calibrating the solder joint height of a resonant column, including a base 1, a sliding seat 3, a spring sliding seat 6, a push rod 7, a support 11 and a card seat 12, wherein the above-mentioned base 1 is a rectangular plate structure, the base 1 is set on the machine platform of the bench drill; the above-mentioned sliding seat 3 is set on the base 1, and the sliding seat 3 slides freely along the longitudinal direction on the base 1; There are two guide rails 5 on the ground, and a chute A extending in the transverse direction is formed between the two guide rails 5; the above-mentioned spring slide seat 6 is embedded in the chute A, and slides freely along the chute A; The direction is inserted on the spring sliding seat 6, and the spring 9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com