Automatic core penetrating and pulling device for stretch bending

An automatic threading and core-pulling technology, applied in the field of stretch-bending equipment, can solve the problems of wasting work cycle time, manpower, and space, and achieve the effects of reducing work cycle time, less manpower consumption, and simple core-pulling and core-pulling process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

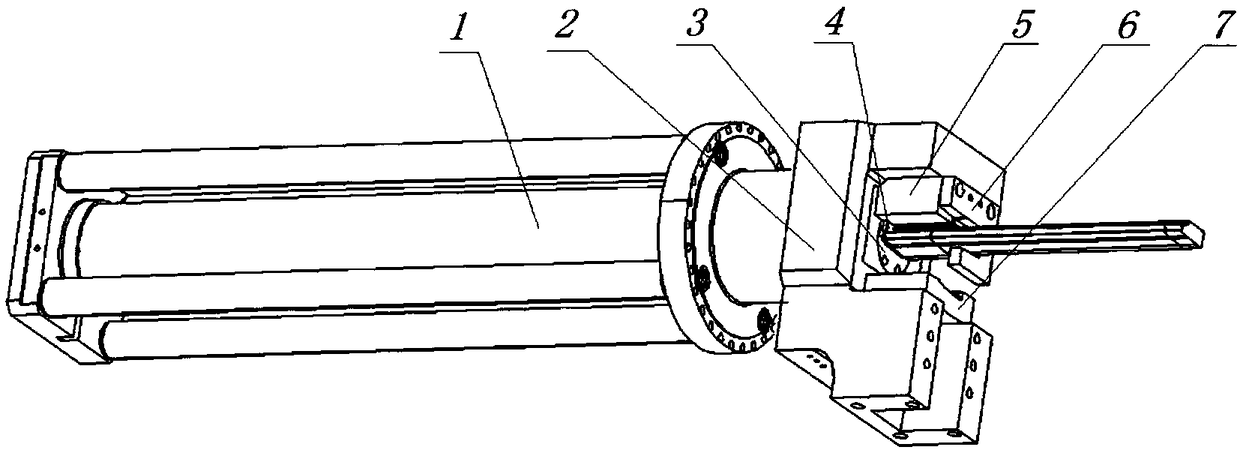

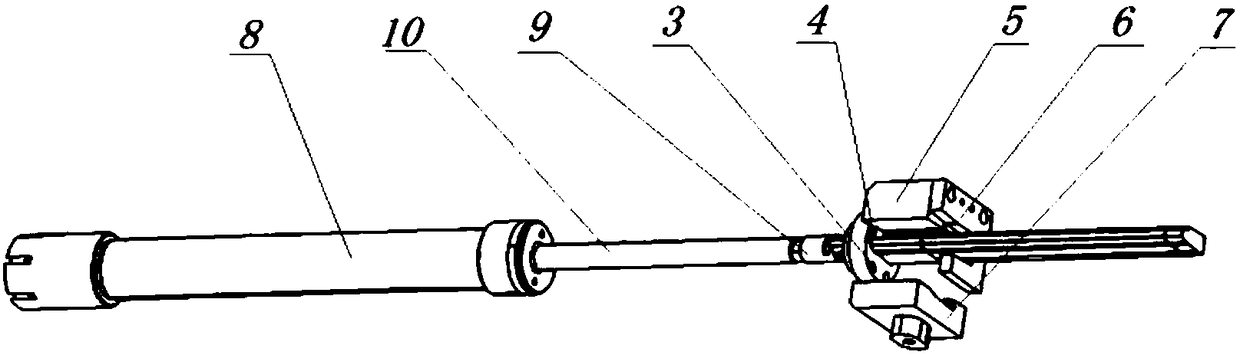

[0013] Such as figure 1 and figure 2 As shown, the present invention includes a "凵"-shaped clamping base 2 composed of the opposite first fixed surface, the second fixed surface and the connection surface between the two, and a through hole is opened on the connection surface, and a connection is made in the through hole. A guide block 3 is provided, and a perforation matching the cross-sectional structure of the core is opened on the guide block 3, and a drive cylinder with an axis perpendicular to the connecting surface is provided on the side facing away from the open surface of the clamping base 2, and the cylinder of the drive cylinder The relative position of the cylinder and the clamping base 2 remains unchanged, and the end of the cylinder rod 10 of the driving cylinder is connected with a connector 9 for connecting with the core. The static clampi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap