Conveying-to-top and installation method with spline alignment

An installation method and spline technology, applied in the field of roof feed installation, can solve the problems of many installation constraints, long installation time, difficult generator installation, etc., and achieve the effects of high matching accuracy, fast alignment and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific drawings and embodiments.

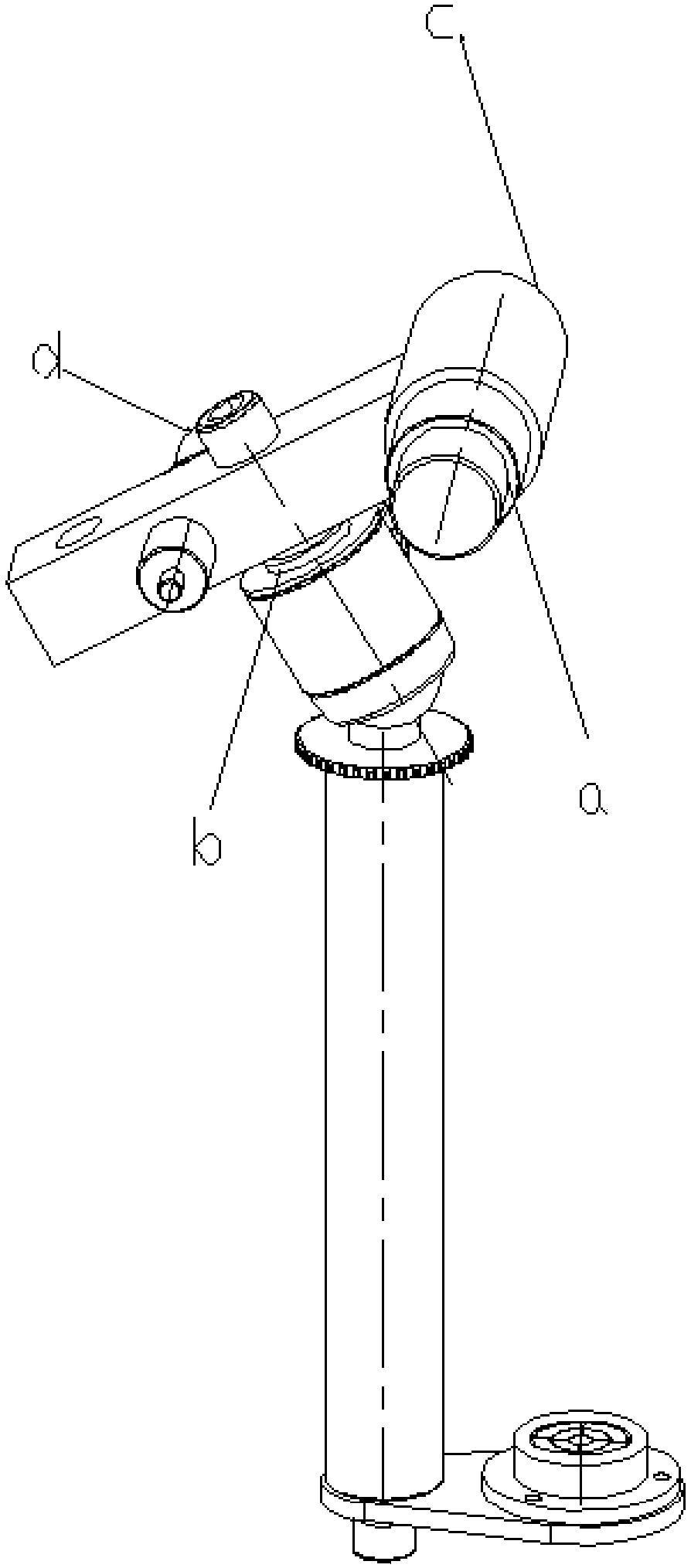

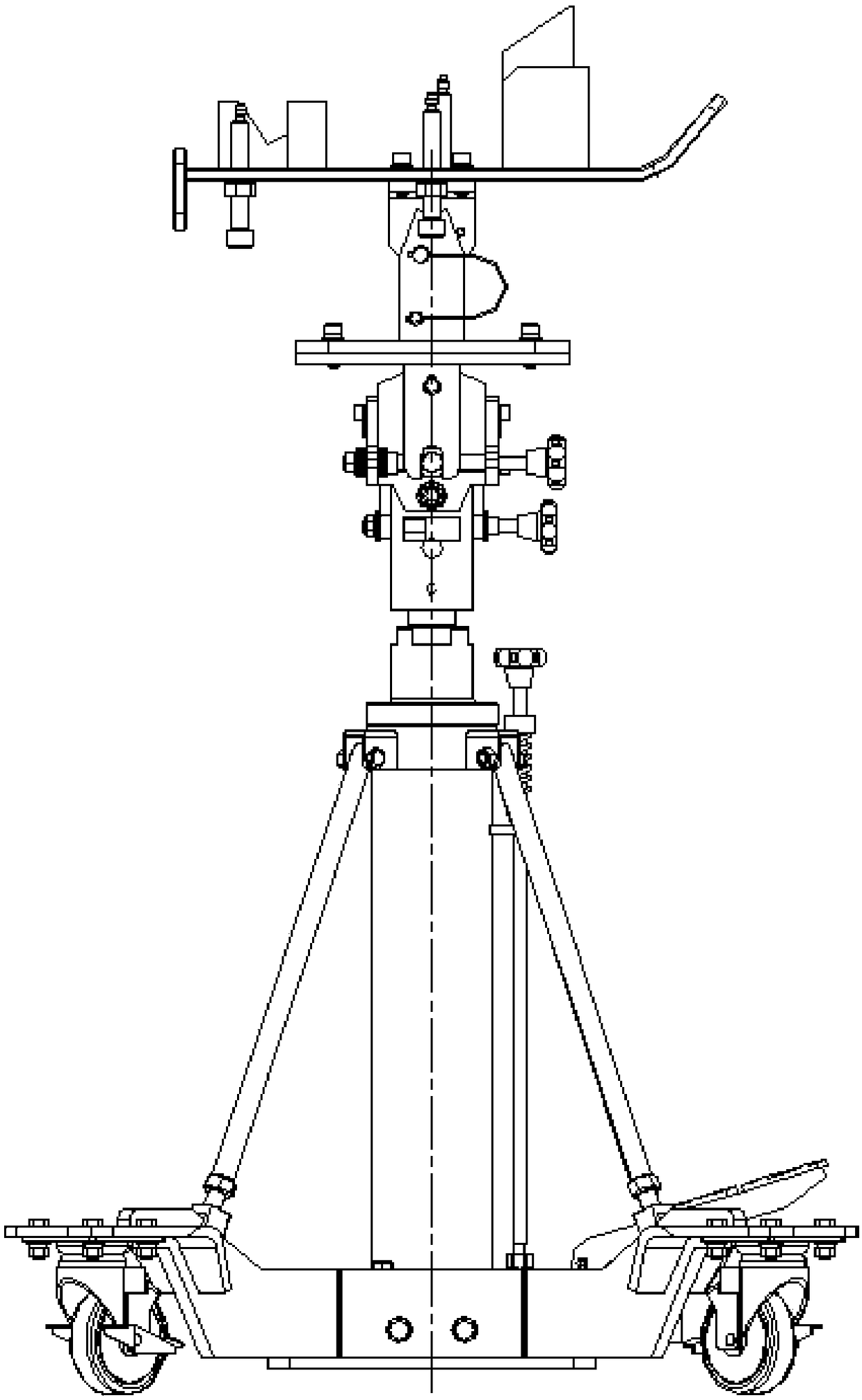

[0027] Such as Figure 1-2 Shown:, a spline-aligned top-feeding installation method, characterized in that,

[0028] Including the following steps:

[0029] Step 1: Put the installed fuel pump regulator on a flexible head of a jacking device for spline alignment installation;

[0030] Step 2: The flexible plug designs the positioning block according to the shape of the pump adjustment, realizes the rapid positioning of the pump adjustment, and positions the pump adjustment to the design state;

[0031] Step 3: Bind the fuel pump regulator and the flexible head together in a criss-cross pattern with locking straps;

[0032] Step 4: Insert the positioning shaft at end a of the rocker-arm plane calibrator into the inner spline of the accessory casing, and at the same time insert the b-end of the double-headed positioning pin into the pin hole on the mounting sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com