Sinking-preventive and antiskid combined scissor jack for wheels

A technology of jacks and wheels, applied in the direction of lifting devices, etc., can solve the problems of inconvenient carrying, troublesome installation and disassembly, low reliability, etc., and achieve the effect of convenient disassembly and assembly, small space occupation and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

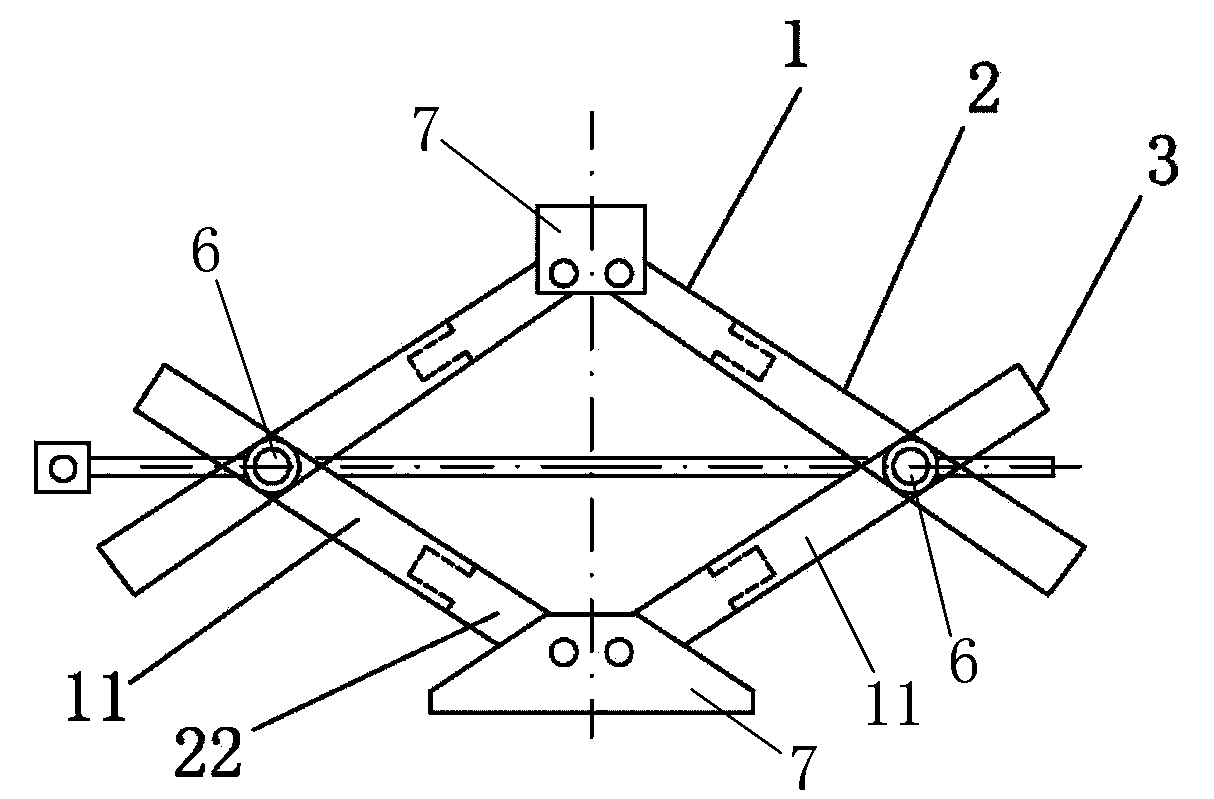

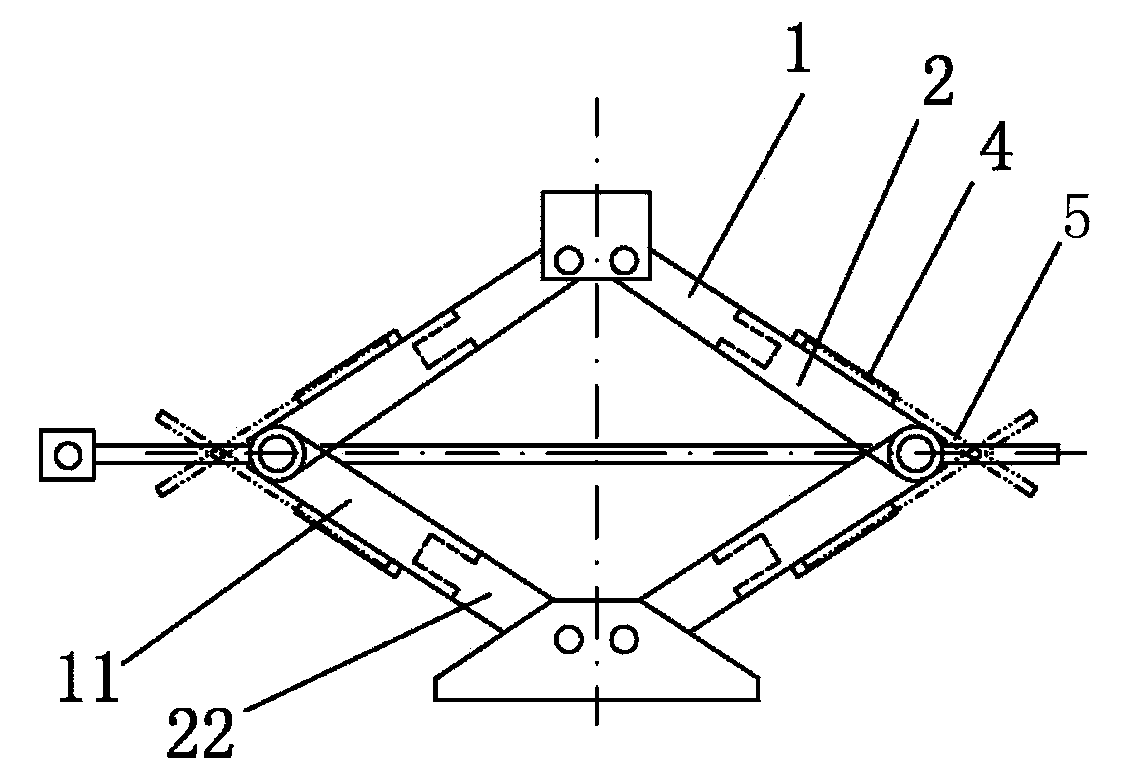

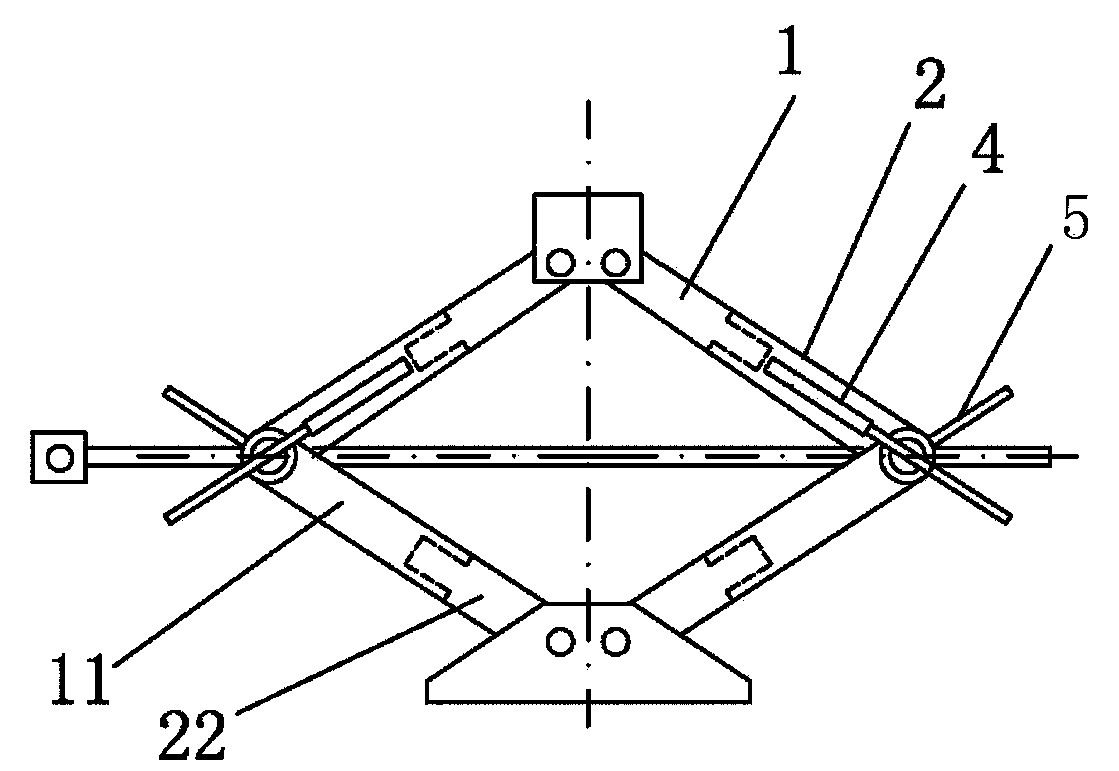

[0016] A combined scissor jack for wheel anti-sinking and anti-slip, such as Figure 1-5 As shown, it includes a jack body with upper and lower hinged seats, left and right hinged arms are arranged between the upper and lower hinged seats of the jack body, and threaded holes and threaded shafts are respectively arranged on the pin shafts arranged in the middle of the left and right hinged arms. Cover, between the bearing pins of the left and right articulated arms, a rotating lead screw is arranged, and these preamble parts all are the structures of the existing scissor jacks. The left and right articulated arms are evenly divided into two parts: the free arms 2, 11 hinged on the pin shaft 6 and the rotating arms 1, 22 hinged on the hinged seat 7, the free arms 2, 11 and the rotating arm 1 , 22 is a detachable connection structure, and there are many detachable connection structures, which can be concave-convex matching plug-in structures, and can be connected by bolts. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com