Swing construction method for bridge and swing bridge system

A construction method and swivel technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of unbalance, high risk, complicated construction, etc., and achieve the effect of convenient installation, strong safety, and close coordination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

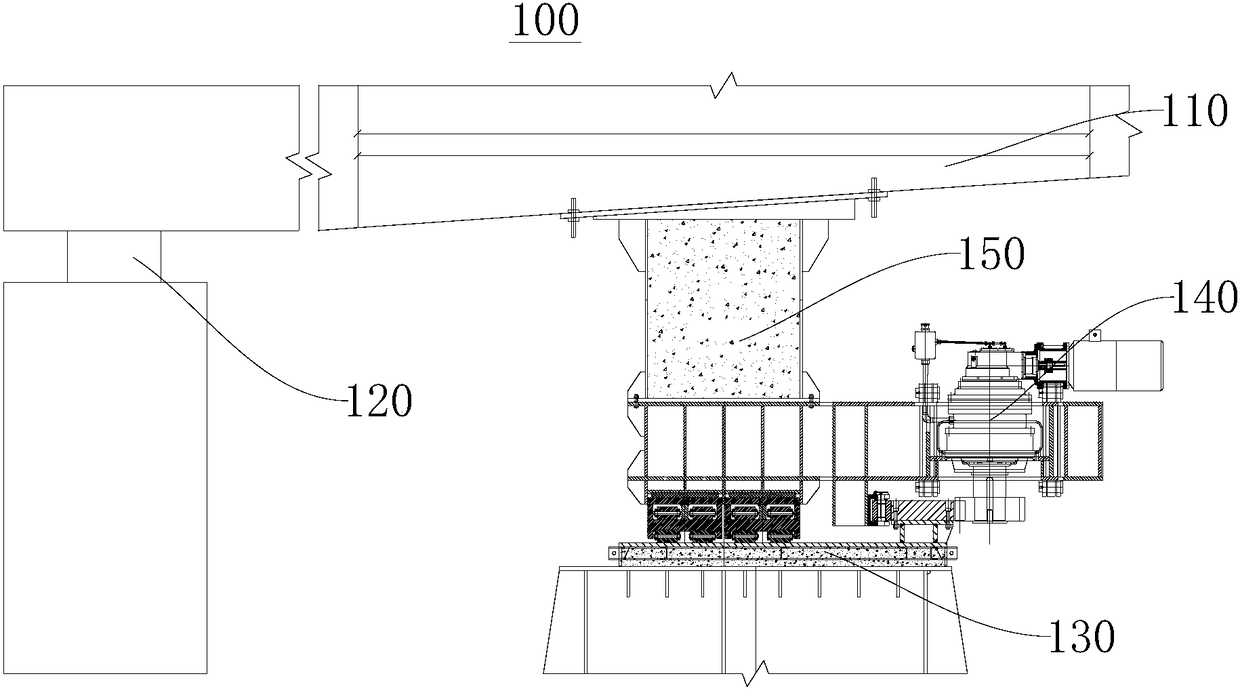

[0032] Please refer to figure 1 , the embodiment of the present invention provides a swivel bridge system 100, which is used for performing swivel movements, thereby completing the construction of the swivel bridge. It is closely matched, stable and reliable, and can stably complete the swivel action when the weight difference between the two ends of the swivel bridge is too large, which is practical, efficient, and safe. The swivel bridge system 100 includes a swivel section 110 , a swivel ball joint 120 , a support rail 130 , a driving device 140 and a front support 150 . The front support 150 and the swivel spherical hinge 120 are arranged at intervals, and both are connected with the swivel section 110 . Driven by the front support 150 , the swivel section 110 can rotate around the swivel spherical hinge 120 to complete the swivel action. The position of the supporting rail 130 is fixed, and the driving device 140 cooperates with the supporting rail 130 so that the drivi...

no. 2 example

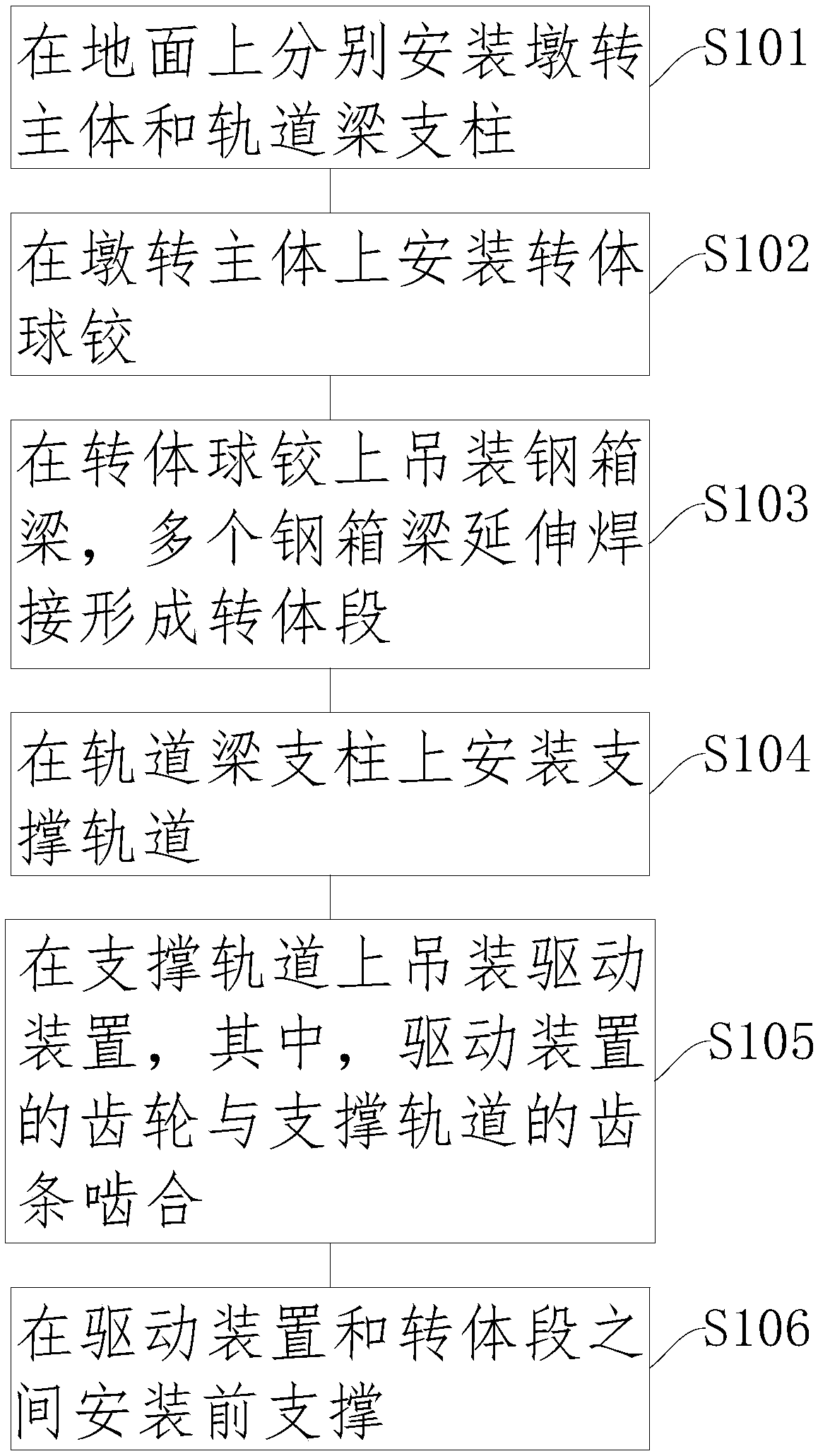

[0036] Please refer to figure 2 , an embodiment of the present invention provides a bridge swivel construction method for constructing a swivel bridge system 100 . It can produce a swivel bridge system 100 that is closely matched, stable and reliable, can stably complete the swivel action when the weight difference between the two ends of the swivel bridge is too large, is practical, efficient, and safe. The swivel bridge system 100 is used for swivel action, thereby completing the construction of the swivel bridge.

[0037] The bridge swivel construction method includes the following steps:

[0038] Step S101: install the main body of the pier and the support of the track beam on the ground respectively.

[0039] It is worth noting that in this step, the construction and installation of the main body of the pier and the track beam pillars can be carried out at the same time or in steps, and the construction sequence of the main body of the pier and the track beam pillars i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com