Manufacturing device of thick film heating stainless steel pipes

A stainless steel tube and thick film heating technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of wasting labor, tools being removed from hands, and low efficiency, so as to facilitate batch processing, avoid reinstallation, Scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

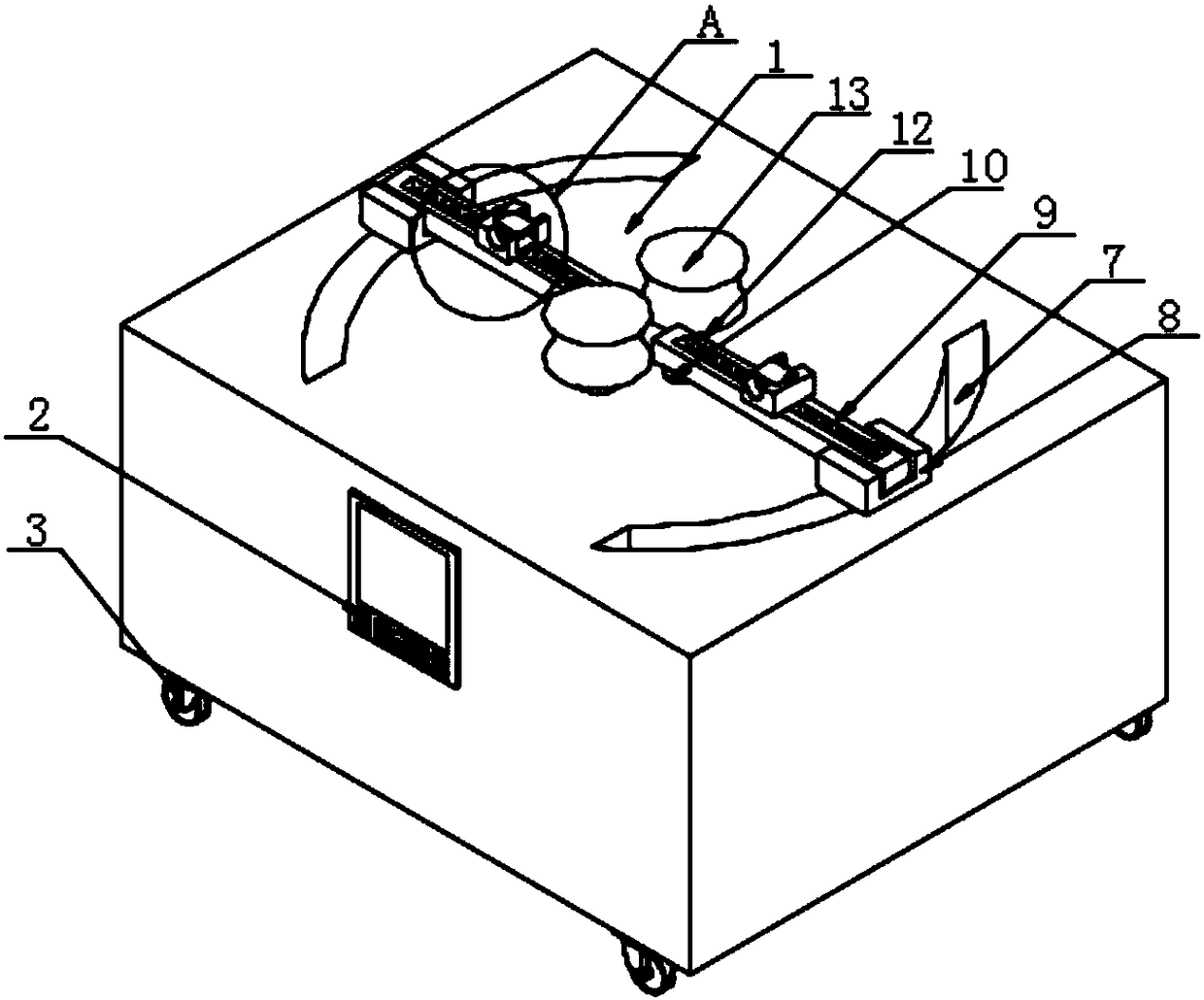

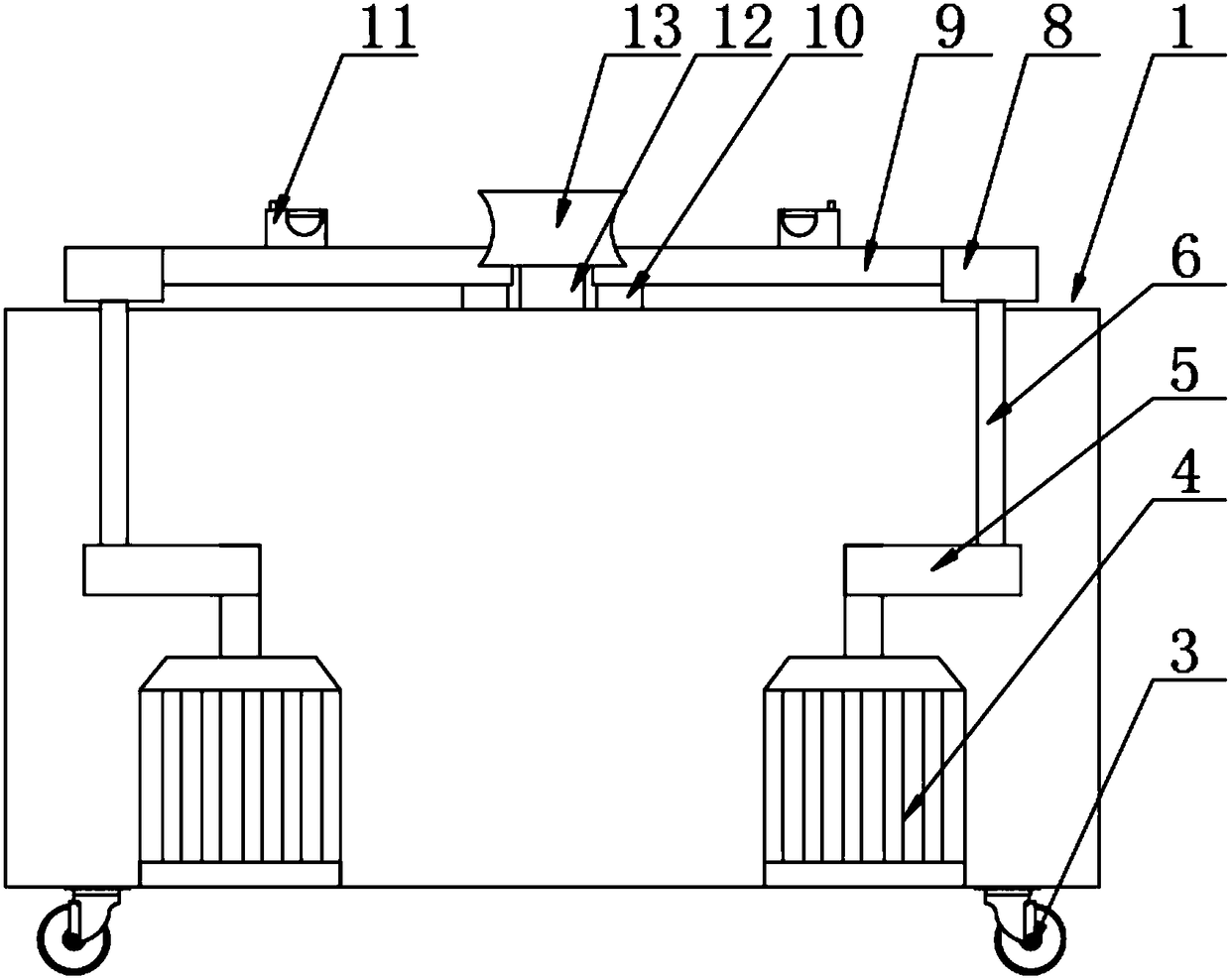

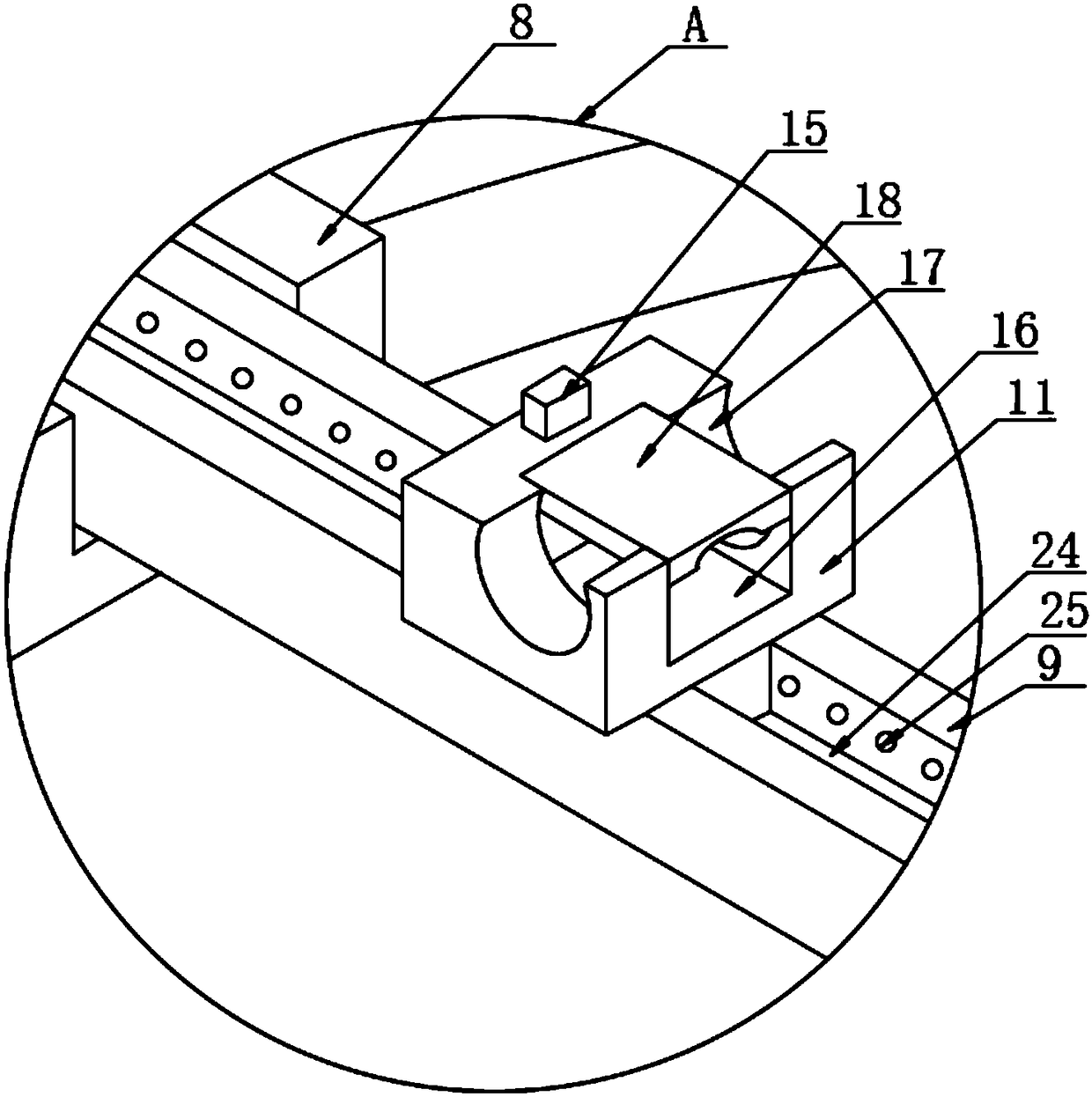

[0019] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, including a box body 1, a control button 2, a roller 3, a motor 4, a control rod 5, a connecting rod 6, a movable groove 7, a mounting plate 8, a connecting plate 9, and a first mounting shaft 10. Mounting seat 11, second mounting shaft 12, bending wheel 13, mounting groove 14, adjusting button 15, fixing groove 16, hand hole 17, positioning plate 18, adjusting rod 19, return spring 20, limit buckle 21, Limiting block 22, trapezoidal block 23, chute 24 and limit hole 25, the bottom of casing 1 is equipped with roller 3 by bolt, one side of casing 1 is embedded with control button 2, and the top of casing 1 is provided with Movable slot 7, the inside of the box body 1 is equipped with a motor 4 through bolts, and a control rod 5 is installed on the output shaft of the motor 4, and a connecting rod 6 is installed on one side of the control rod 5 through gear meshing, and the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com