Cloud-based self-adaptive saw tooth grinding method for saw blade grinding machine

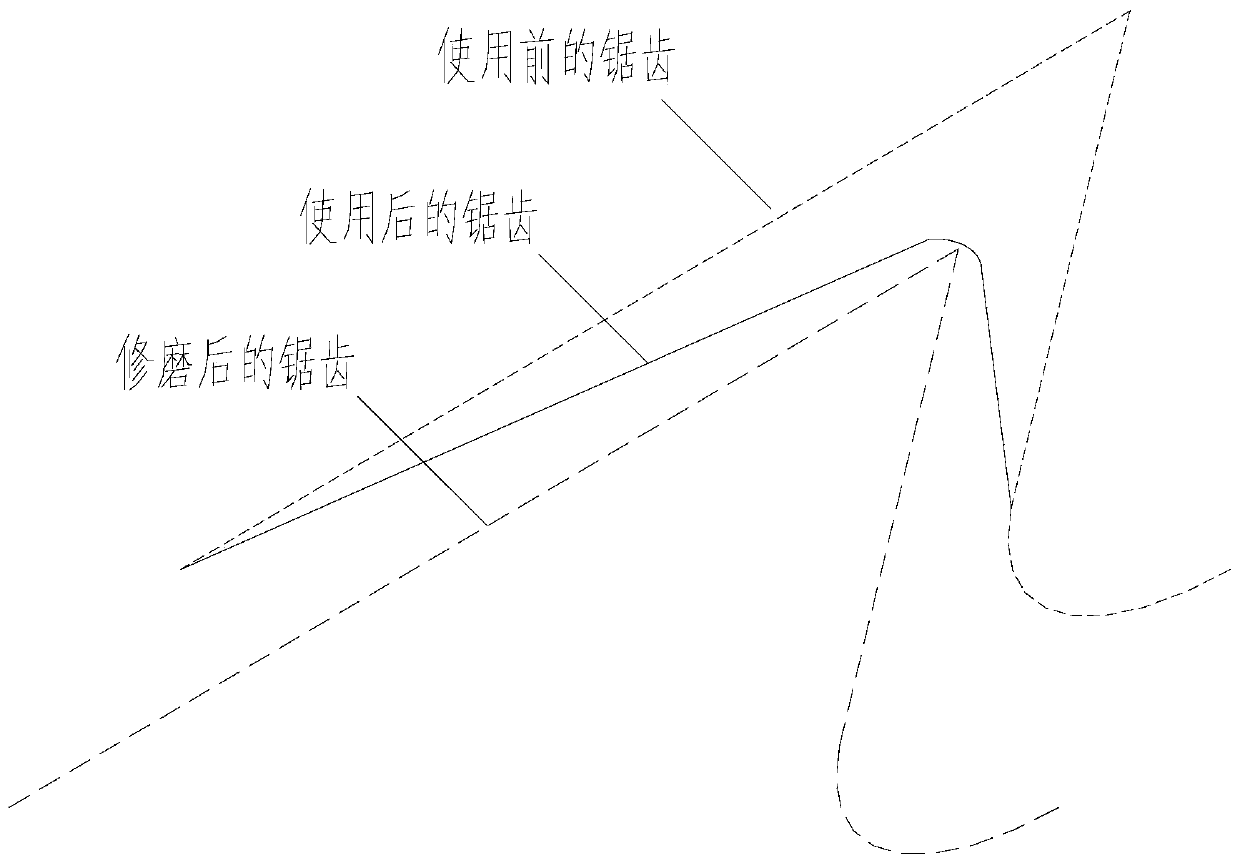

A saw blade gear grinding machine, the technology of the gear grinding machine, which is applied to the tool trimming of the sawing machine device, metal sawing equipment, metal processing equipment, etc., can solve the problems of shortening the overall service life of the saw blade, wrong selection of saw tooth angle parameters, and bluntness and other problems, to achieve the effect of better prediction of saw blade working conditions, easy realization, and avoiding bluntness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

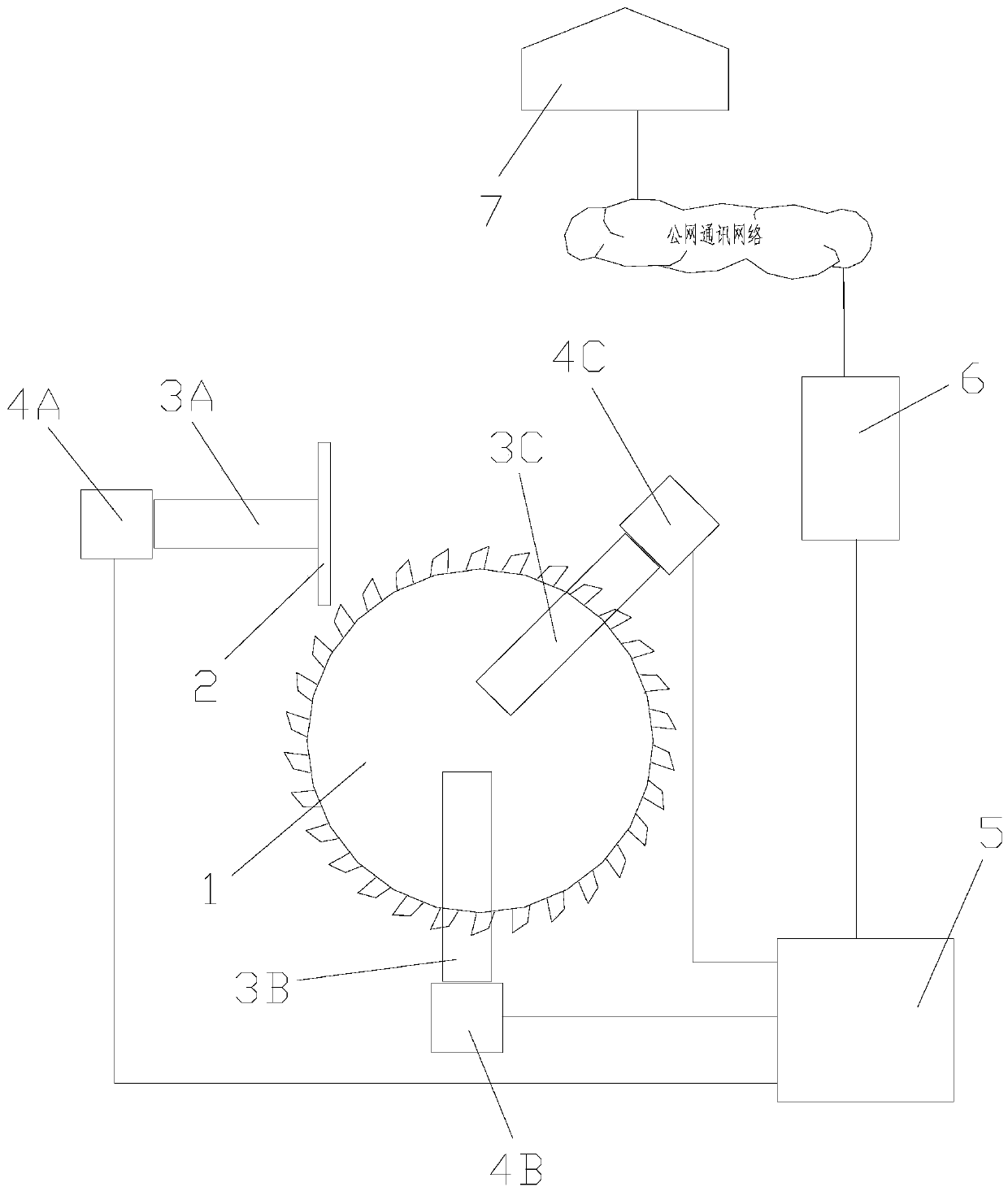

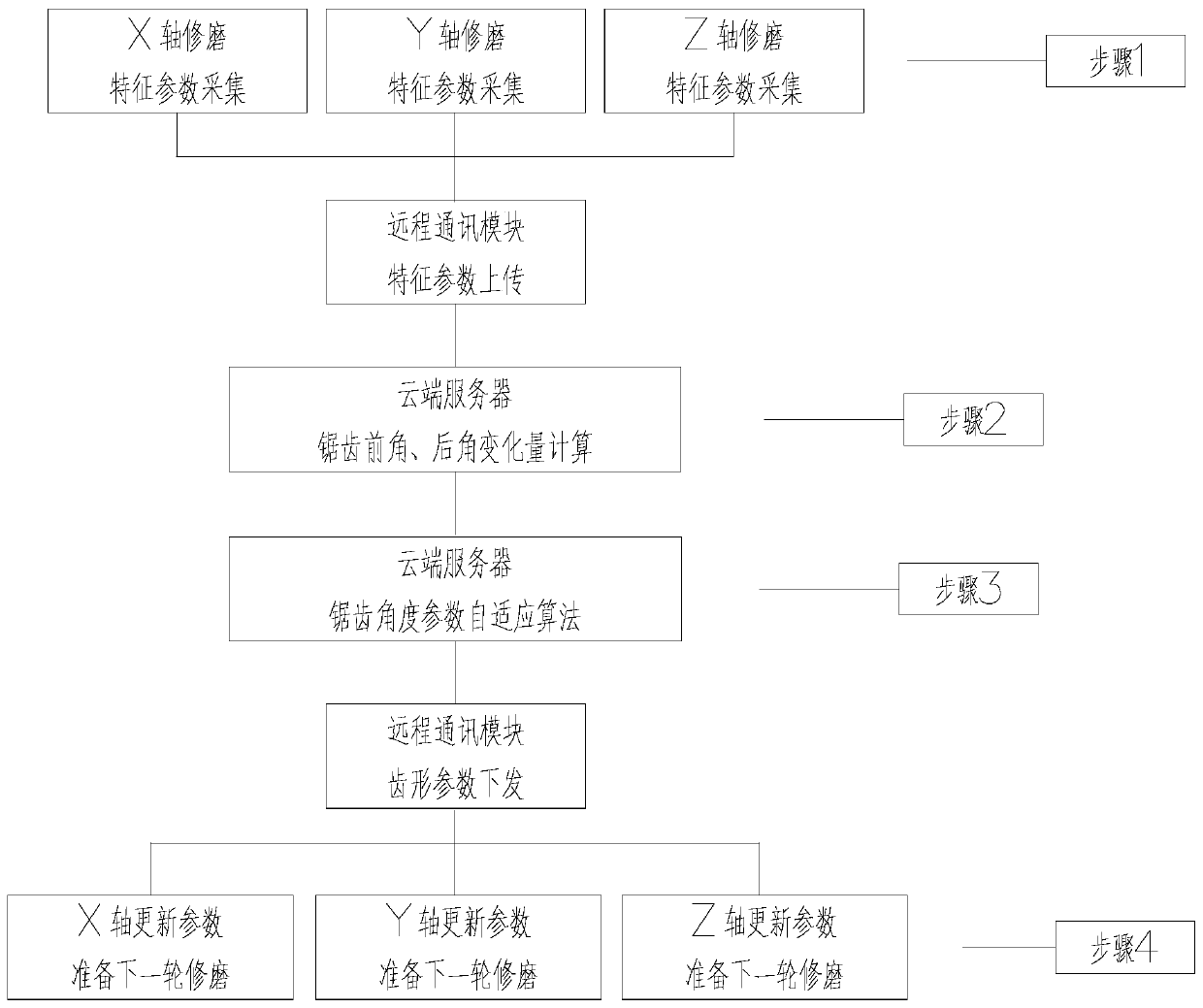

[0030] The present invention will be further explained below in conjunction with the drawings:

[0031] With reference to the drawings: the cloud-based adaptive saw tooth grinding method of the saw blade gear grinding machine in this embodiment includes the X axis of the gear grinding machine and its drive motor 3A, the Y axis of the gear grinding machine and its drive motor 3B, and the grinding Gear machine R axis and its drive motor 3C, X axis motor driver 4A, Y axis motor driver 4B, R axis motor driver 4C, gear grinding machine controller 5, remote communication module 6, cloud server 7;

[0032] The X axis of the gear grinding machine and its drive motor 3A are connected with the X axis motor driver 4A;

[0033] The Y axis of the gear grinding machine and its drive motor 3B are connected with the Y axis motor driver 4B;

[0034] The R axis of the gear grinding machine and its drive motor 3C are connected with the R axis motor driver 4C;

[0035] X-axis motor driver 4A, Y-axis motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com