A Passive Follow-up Sealing Structure

A follow-up, main structure technology, used in transportation and packaging, aircraft parts, aircraft control, etc., can solve problems such as short service life, poor stiffness, and poor sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing the present invention is described in further detail, please refer to Figure 1 to Figure 3 .

[0014] Such as figure 1 As shown, it is a general sealing structure, and its structure adopts superelastic material as the sealing plate material, which can meet the sealing requirements, but the service life is short, the reliability is low, and the material requirements are high.

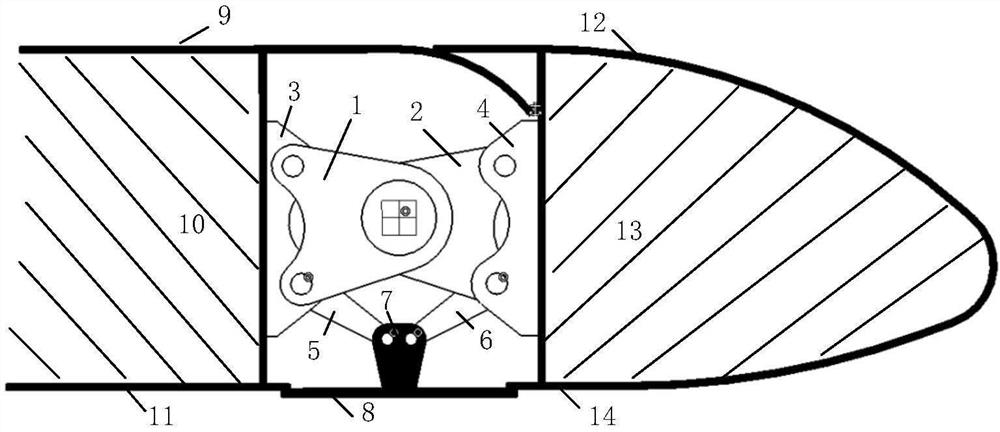

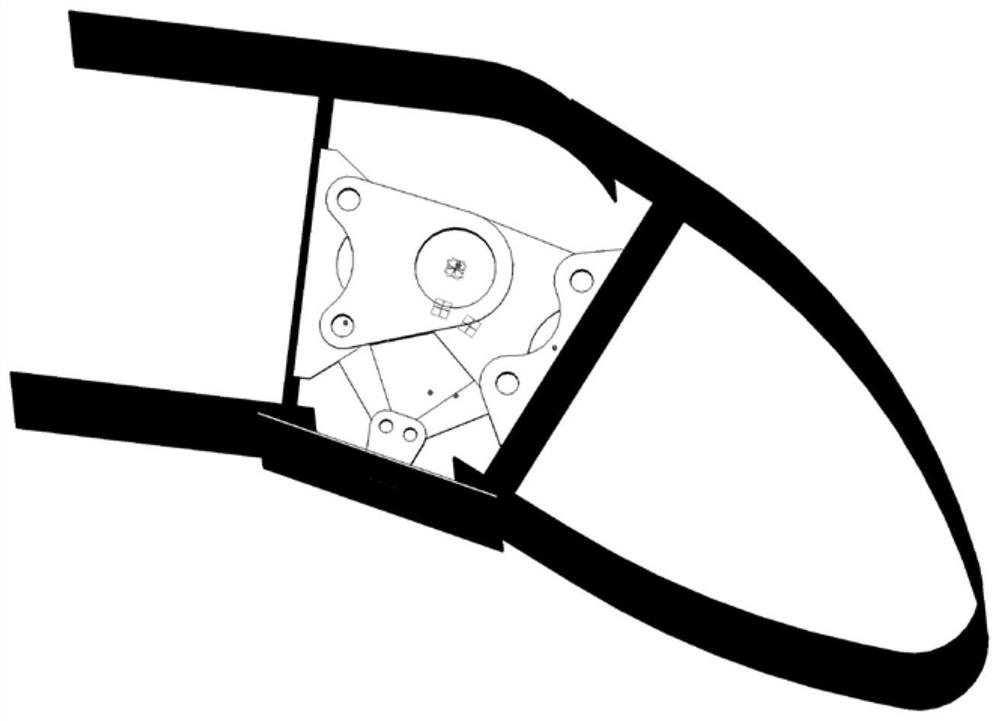

[0015] Such as Figure 2-3 As shown, it is a schematic diagram of the structure of the present invention, a passive follow-up sealing structure, including a fixed airfoil joint 1, a rudder surface joint 2, a fixed airfoil joint support 3, a rudder surface joint support 4, a connecting rod 5, Connecting rod 6, sealing plate support 7, sealing plate 8, skin on fixed wing surface 9, lower skin on fixed wing surface 11, skin on rudder surface 12, lower skin on rudder surface 14, the sealing structure It also includes a fixed airfoil main structure 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com