Ring shear apparatus considering constant stiffness, constant volume and constant stress,

A constant stiffness and stress technique, which is used in the field of experimental devices for measuring the shear characteristics of different soils and interfaces under different contact conditions, can solve the problems that the interface boundary effect has a large influence, is complicated, and cannot achieve the control conditions of constant stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

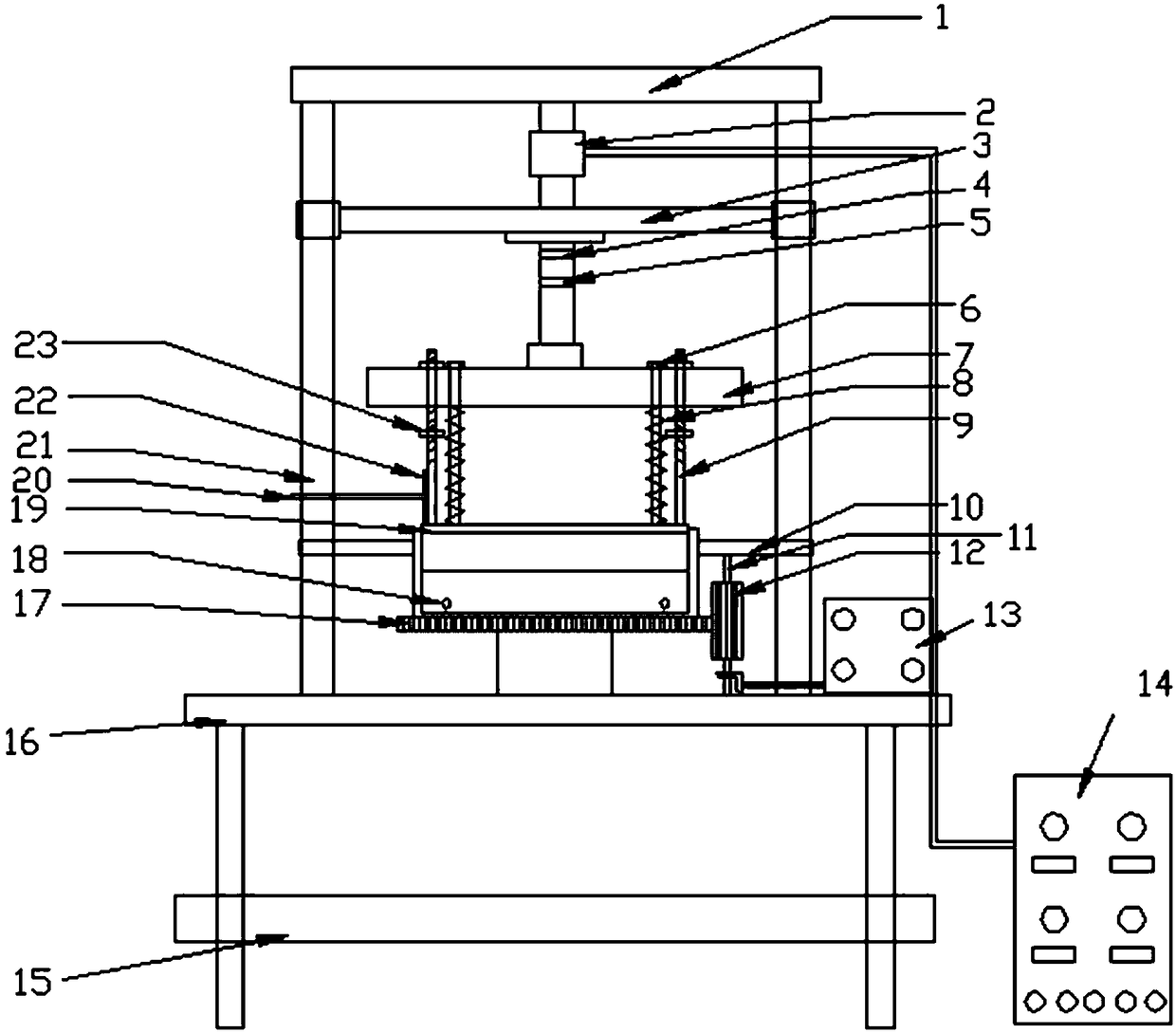

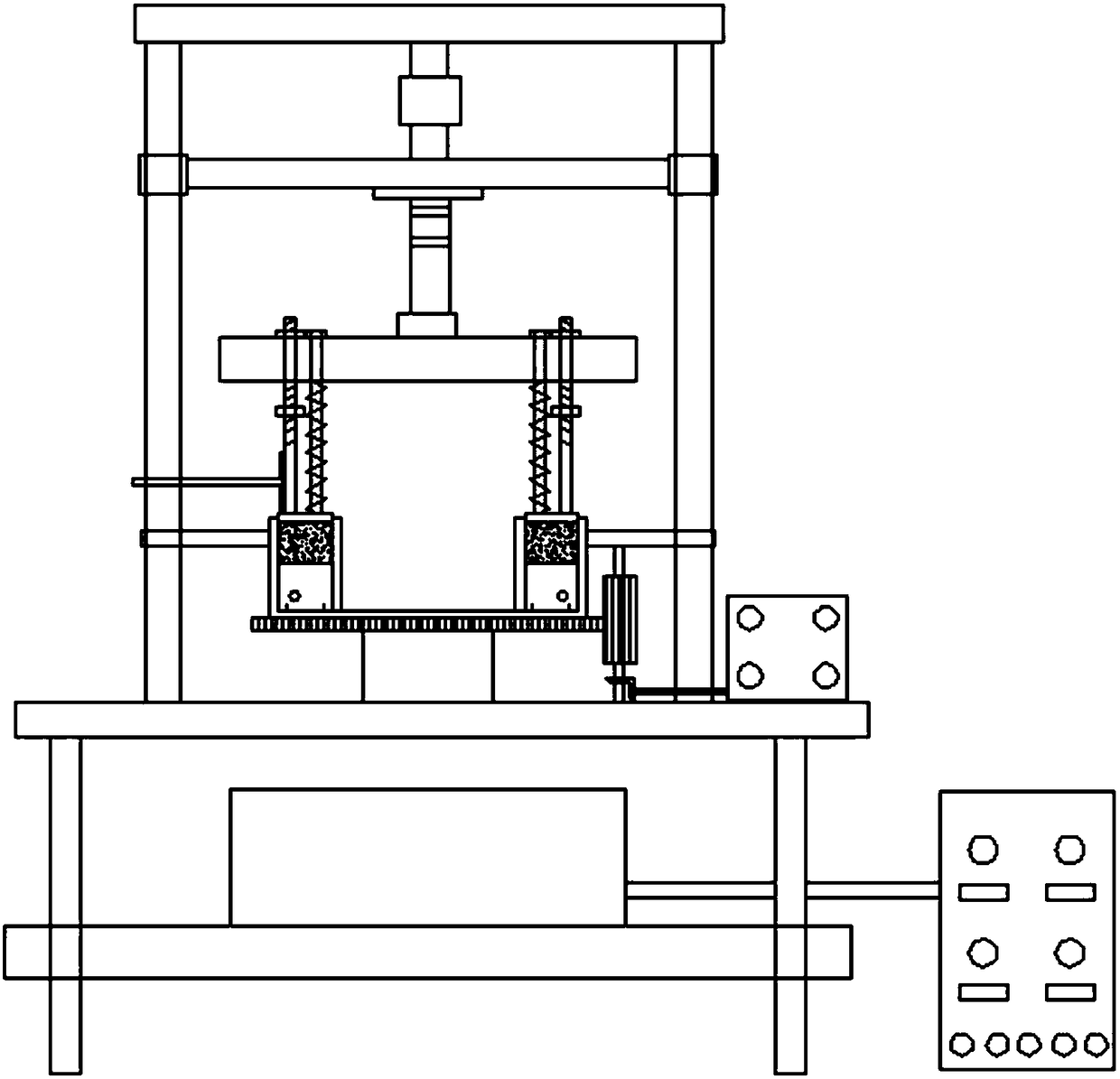

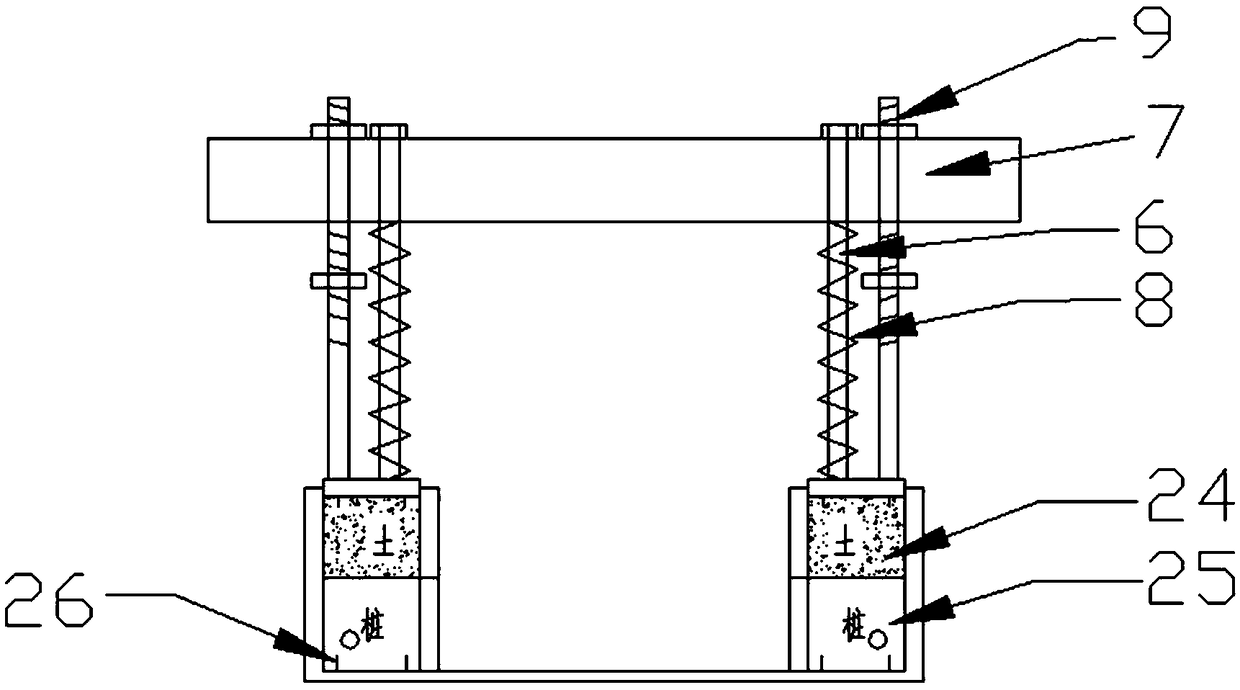

[0022] refer to Figure 1-4 , the ring shear instrument of the present invention that can consider constant stiffness, constant volume and constant stress includes a frame, a shearing system, a torsion device, a hydraulic loading system, and a sensor detection system;

[0023] Frame comprises upper crossbeam 1, lower crossbeam 15, pedestal desktop 16, column 21, horizontal support 10, vertical support 11, displacement meter horizontal support 20 etc., each part is welded as a whole.

[0024] The shearing system includes an upper shearing box 24 and a lower shearing box 25, both of which are ring-shaped, respectively containing the soil body and the structure interface to simulate the shearing behavior of the interface. The steel sheet is used to fix the soil body and the pile body, and the upper shear box 24 is made of plexiglass, which is convenient to utilize the CCD camera to directly observe the change situation of soil particles and structure in the shearing process, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com