Load applying method of refractory material tester

A technology for applying loads and refractory materials, applied in the field of testing instruments, can solve the problems of changes in the quality of furnace lining materials and heating elements, easy deviation of the direction of applied pressure, affecting the accuracy of experimental results, etc., to achieve flexible and convenient measurement, tension reduction, The effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

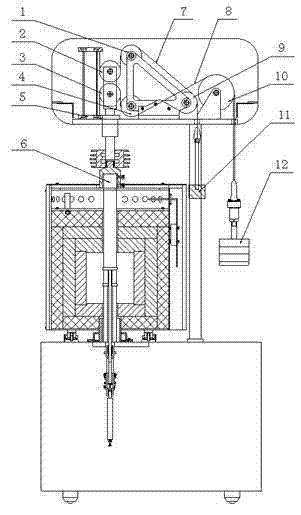

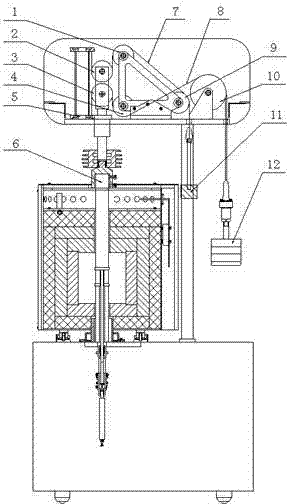

[0018] Embodiment 1: The method of applying load of the refractory material pressure creep tester, applying a constant stress with a movable pulley mechanism. Two sets of stress transfer mechanisms composed of movable pulleys, fixed pulleys, and flexible steel wire ropes are respectively responsible for applying loads and adjusting balance. Two of the movable pulleys form a movable pulley block, so that the quality of load and adjustment balance is greatly reduced.

[0019] The load-applying mechanism of the refractory pressure creep tester includes a group of stress transmission mechanisms composed of fixed pulley II4, fixed pulley IV10, lower moving pulley 3 and flexible steel wire rope II8, which bear the role of applying load, and the flexible steel wire rope II8 One end is fixed on the frame 5, and the other end carries the test weight 12. The direction of output driving force of this group of lower moving pulleys 3 is downward; The transmission mechanism is responsible f...

Embodiment 2

[0020] Embodiment 2: On the basis of Embodiment 1, the method and mechanism of applying load applied to the load softening temperature tester for refractory materials.

Embodiment 3

[0021] Embodiment 3: On the basis of Embodiment 1, the method and mechanism of applying load or displacement tracking applied to the refractory material thermal expansion tester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com