Method for evaluating lithium ion battery formation process

A technology of lithium ion battery and evaluation method, applied in the field of evaluation of lithium ion battery formation process, can solve the problems of long time consumption and poor practicability, and achieve the effect of reducing side reactions, low solubility, good thermal stability and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

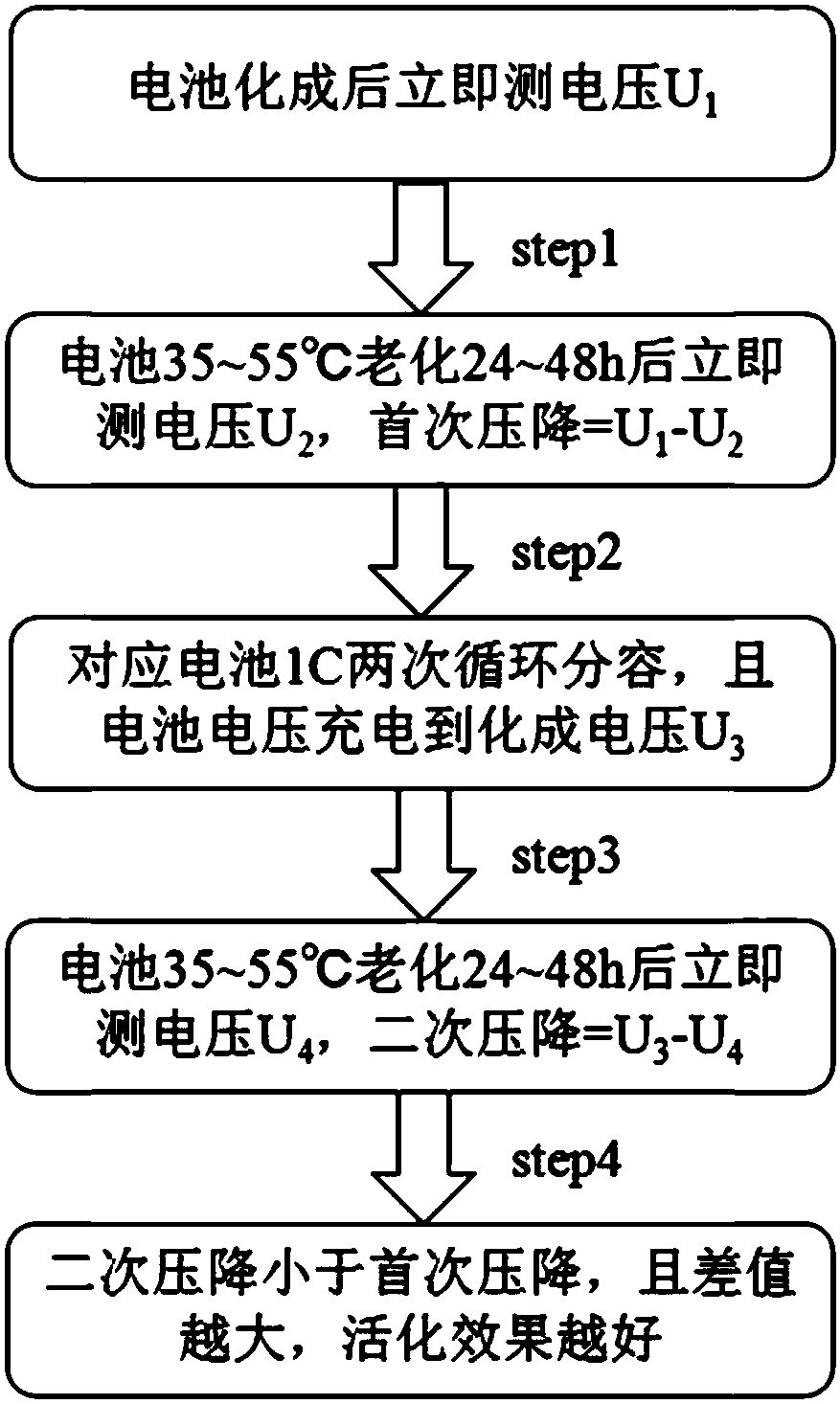

[0020] The evaluation method of the lithium-ion battery forming process of the present embodiment, the technological process is as follows figure 1 As shown, the following steps are taken:

[0021] 1) After the lithium-ion battery is formed, its voltage is detected as U 1 , then the lithium-ion battery was aged at 45°C for 24h, and the detection voltage was U 2 , record the first pressure drop ΔU 1 =U 1 -U 2 ;

[0022] 2) The aging battery in step 1) is subjected to cyclic discharge and charge at a rate of 1C / 1C, the number of cycles is two, and it is charged to the cut-off voltage of the formation process, and then the specific voltage value is detected, which is recorded as U 3 ; Then age the voltage after cyclic discharge and charge at 45°C for 24h, and the detection voltage is U 4 , record the secondary pressure drop ΔU 2 =U 3 -U 4 ;

[0023] 3) Calculate the difference between the first pressure drop and the second pressure drop ΔU=ΔU 1 -ΔU 2 , comparing the Δ...

Embodiment 2

[0025] The evaluation method of the lithium-ion battery forming process of the present embodiment, the technological process is as follows figure 1 As shown, the following steps are taken:

[0026] 1) After the lithium-ion battery is formed, its voltage is detected as U 1 , then the lithium-ion battery was aged at 35°C for 48h, and the detection voltage was U 2 , record the first pressure drop ΔU 1 =U 1 -U 2 ;

[0027] 2) The aging battery in step 1) is subjected to cyclic discharge and charge at a rate of 1C / 1C, the number of cycles is two, and it is charged to the cut-off voltage of the formation process, and then the specific voltage value is detected, which is recorded as U 3 ; Then age the voltage after cyclic discharge and charge at 35°C for 48h, and the detection voltage is U 4 , record the secondary pressure drop ΔU 2 =U 3 -U 4 ;

[0028] 3) Calculate the difference between the first pressure drop and the second pressure drop ΔU=ΔU 1 -ΔU 2 , comparing the Δ...

Embodiment 3

[0030] The evaluation method of the lithium-ion battery forming process of the present embodiment, the technological process is as follows figure 1 As shown, the following steps are taken:

[0031] 1) After the lithium-ion battery is formed, its voltage is detected as U 1 , then the lithium-ion battery was aged at 55°C for 24h, and the detection voltage was U 2 , record the first pressure drop ΔU 1 =U 1 -U 2 ;

[0032] 2) The aging battery in step 1) is subjected to cyclic discharge and charge at a rate of 1C / 1C, the number of cycles is two, and it is charged to the cut-off voltage of the formation process, and then the specific voltage value is detected, which is recorded as U 3 ; Then age the voltage after cyclic discharge and charge at 55°C for 24h, and the detection voltage is U 4 , record the secondary pressure drop ΔU 2 =U 3 -U 4 ;

[0033] 3) Calculate the difference between the first pressure drop and the second pressure drop ΔU=ΔU 1 -ΔU 2 , comparing the Δ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com