Assembling and disassembling method of double opening and closing hydrogen storage valve

A hydrogen storage and valve body technology, which is applied to the container discharge method, container filling method, container structure installation device, etc., can solve the problems of not being able to provide a good sealing service life, safe use, leakage, and inconvenient installation and adaptation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

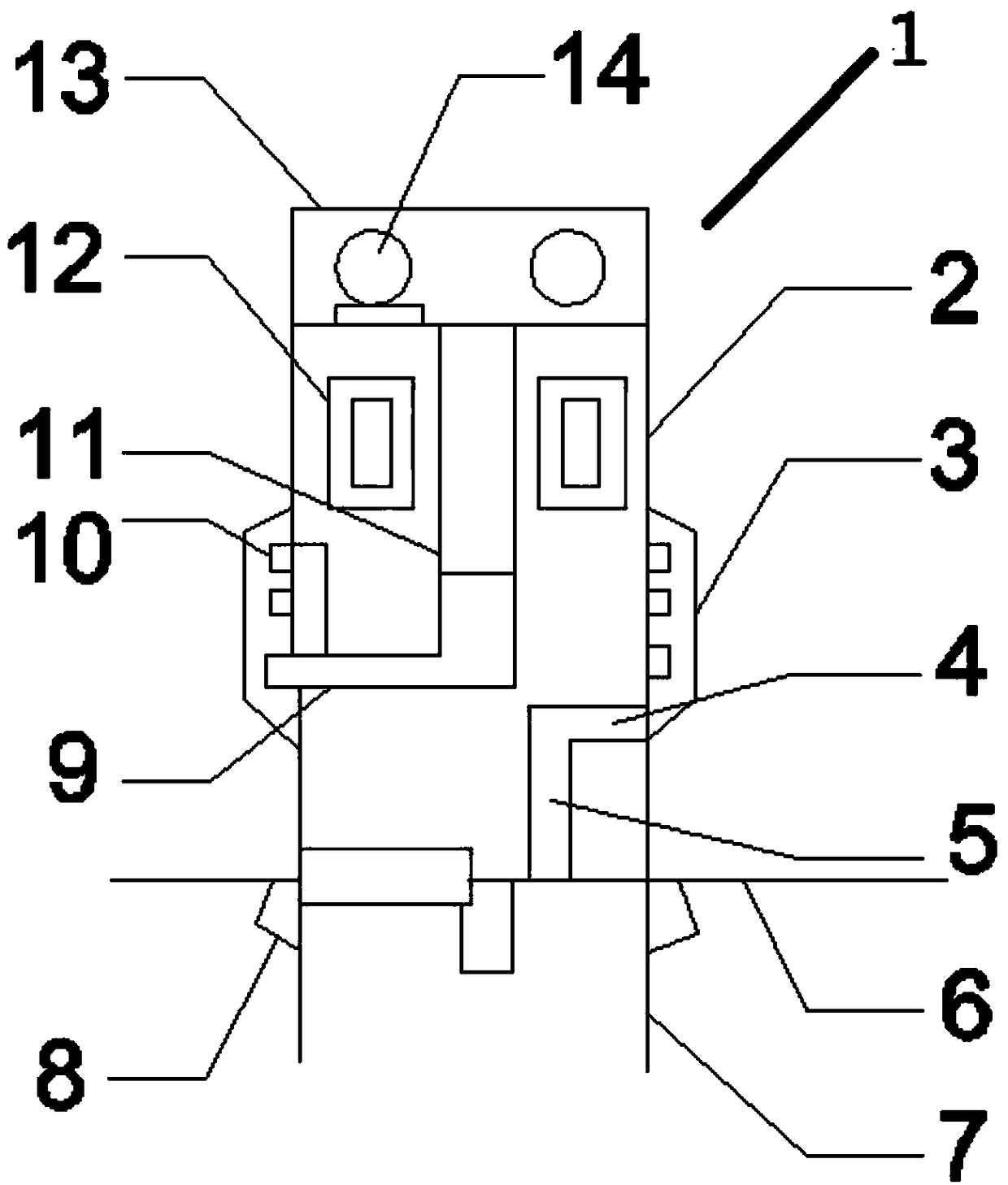

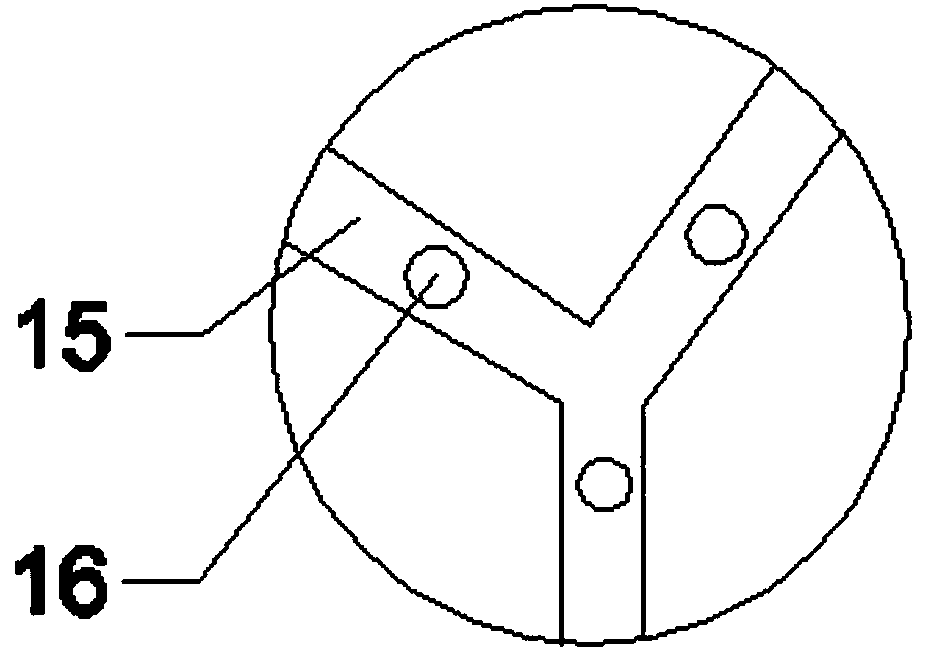

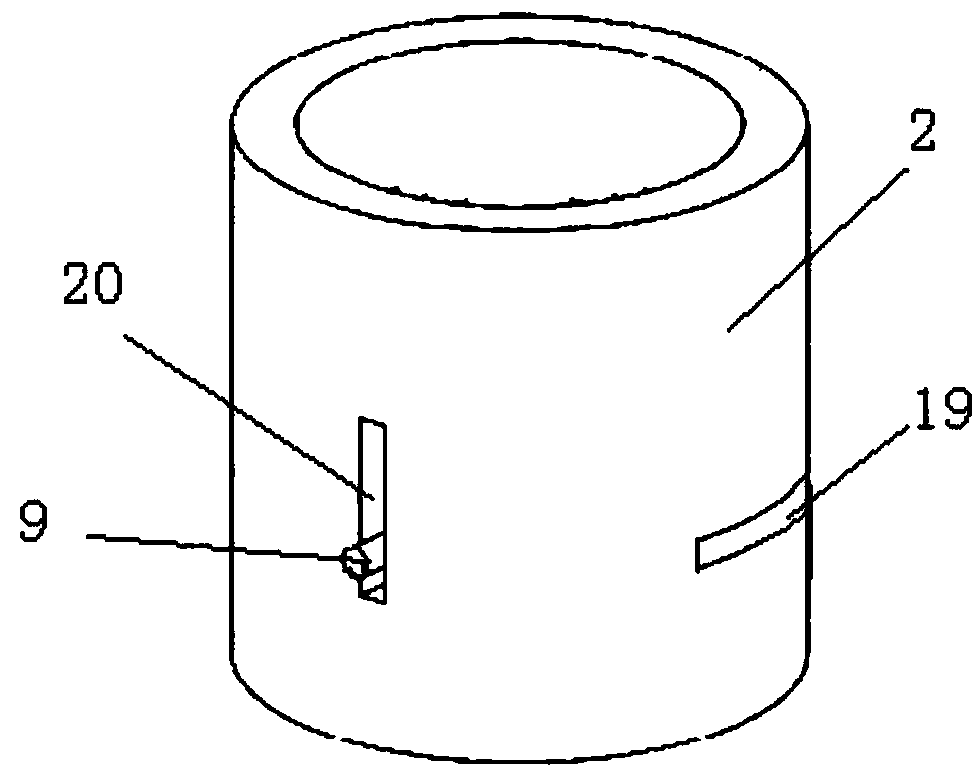

[0033] A loading and unloading method for a double opening and closing hydrogen storage valve, comprising a valve body, a hand wheel, a first support rod, a second support rod, a cylindrical connector, a pawl, a third support rod, a spiral groove, an armature, and an electromagnetic coil , piston, outlet, fan bone channel, one-way valve, storage part, fan-shaped closing part, horizontal groove, vertical groove, electronic drive module; the valve includes double drive module, double opening and closing module, docking module; the valve body has a horizontal Groove, vertical groove, the distance between the two grooves in the circumferential direction is equal to 1 / 4 of the circumference of the valve body; the overall assembly method of the valve is as follows: firstly install all parts into the valve body, and then install the valve body and the cylindrical connector through the thread Connect to form a whole, and finally put the whole into the orifice of the corresponding hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com