A hydrogen storage system

A hydrogen storage and hydrogen storage tank technology, applied in the field of hydrogen storage systems, can solve problems such as thinness, cost increase, leakage, etc., and achieve the effect of improving safety performance and enhancing sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

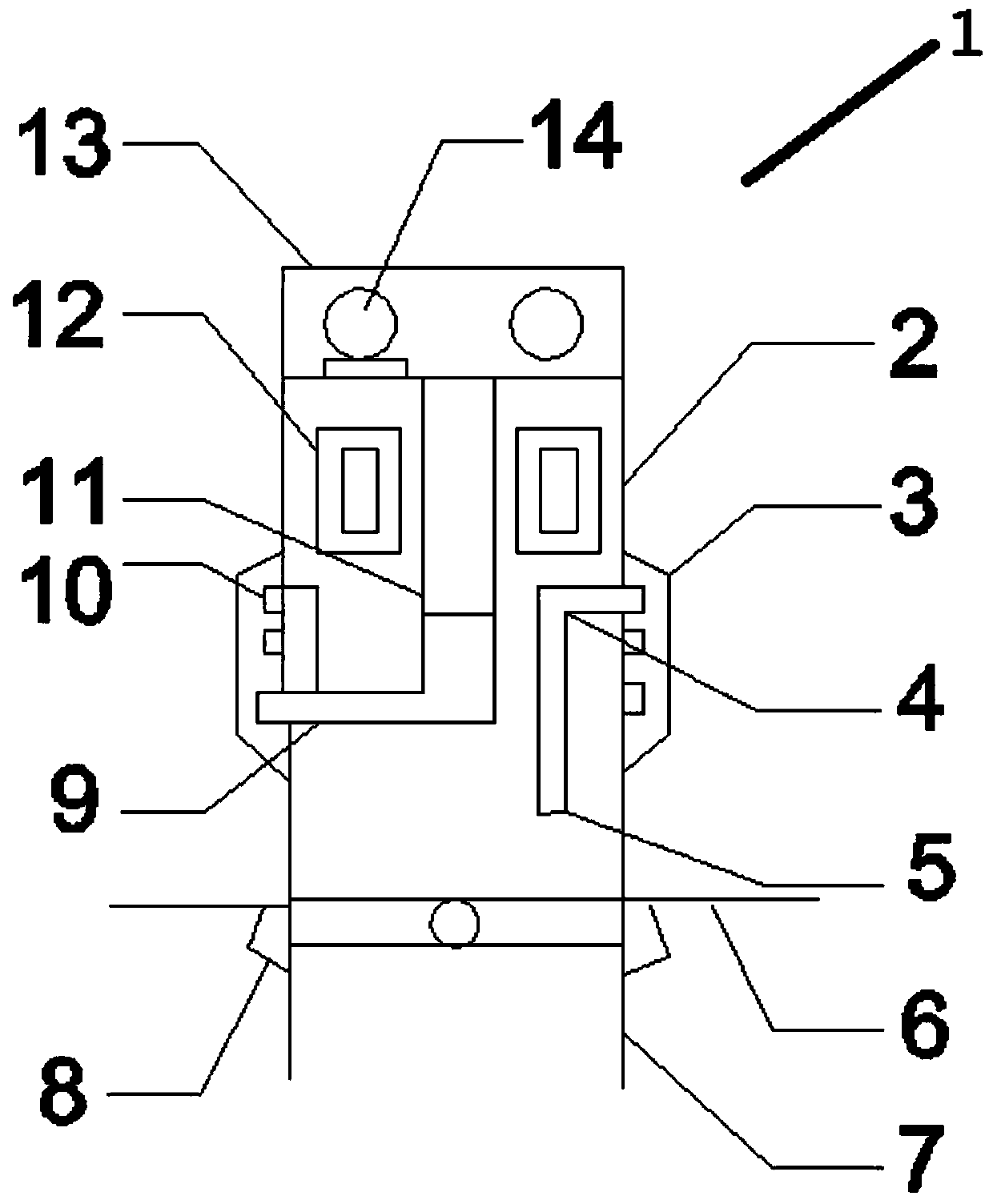

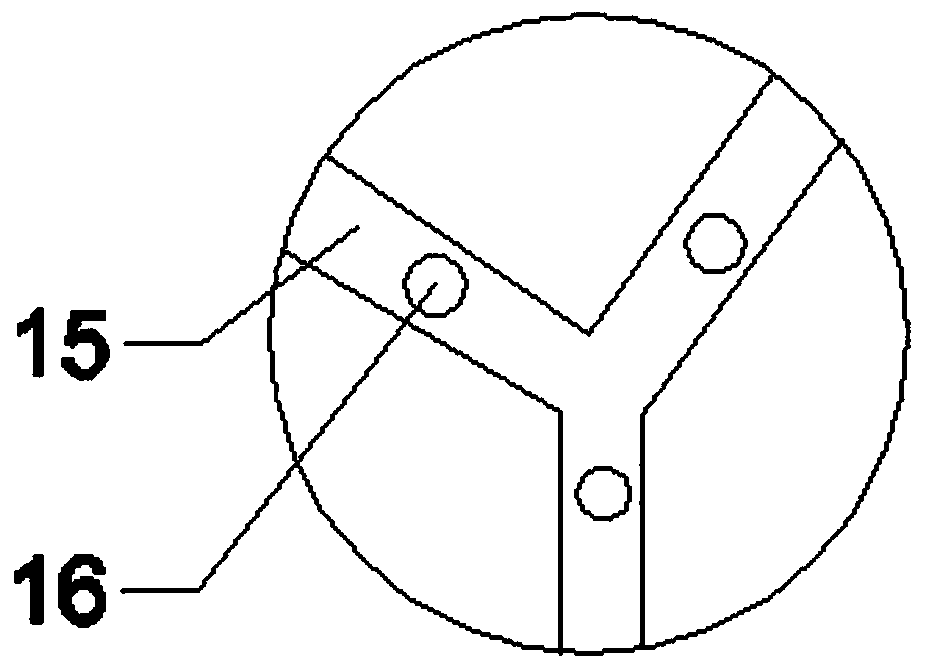

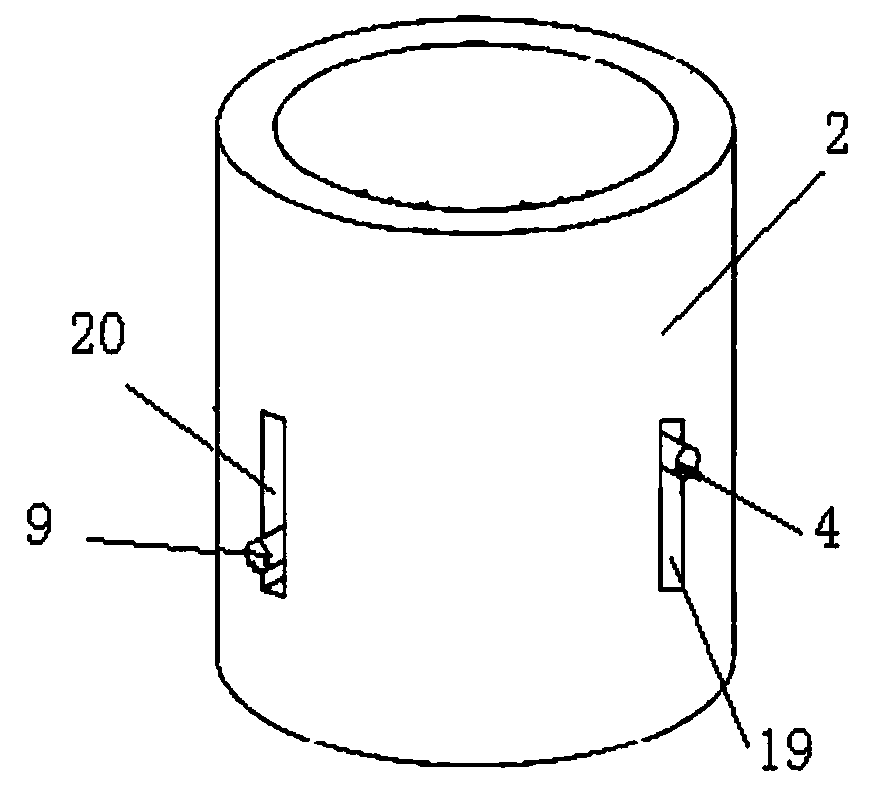

[0038] A hydrogen storage system, including a hydrogen storage tank and a hydrogen storage valve. The hydrogen storage tank includes a surface layer, a tank body, an inner tank, a tank plug, and an upper cover. The surface layer, the tank body, and the inner tank are sequentially arranged from the outside to the inside. The tank body upwardly forms a closure, and the liner is located below the closure. When the seal is not opened, the closure contains the can plug. When in use, the closure contains the hydrogen storage valve. The upper cover is threaded on the closure. The surface layer is The fiber winding layer, the inner liner is made of stainless steel; the hydrogen storage valve includes a valve body, a hand wheel, a first pole, a second pole, a cylindrical connector, a pawl, a third pole, a spiral groove, Armature, electromagnetic coil, piston, outlet, fan bone channel, one-way valve, valve plate, magnetic block, first vertical slot, second vertical slot, electronic drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com