Stepping diaphragm structure provided with dimmer conversion device

A technology of conversion device and light reduction film, which is applied in the direction of aperture, optics, camera, etc., can solve the problems of not being able to obtain a long enough shutter time, and cannot achieve shooting effects, etc., and achieve the effect of simple structure, convenient operation, and improved degree of precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

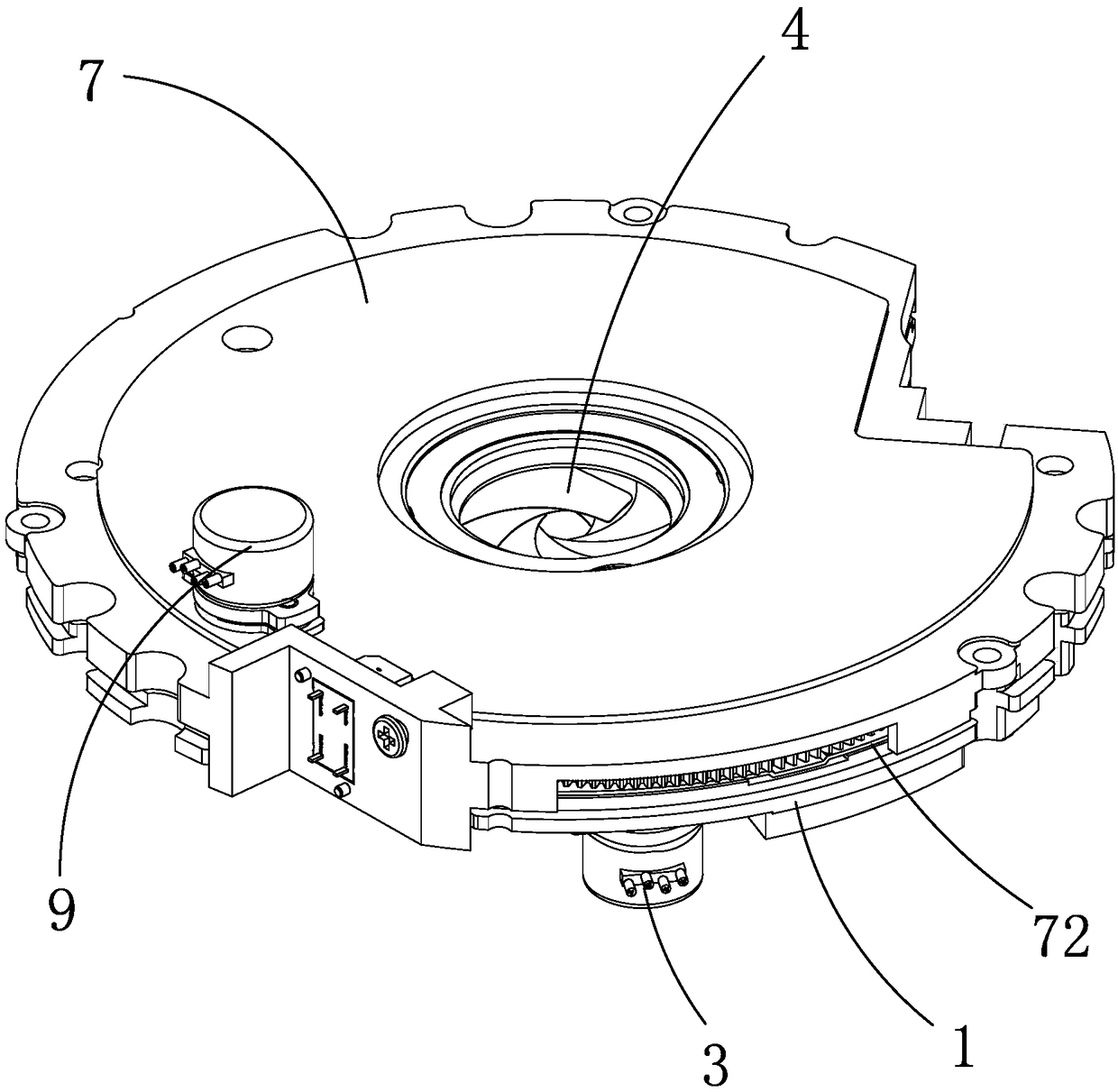

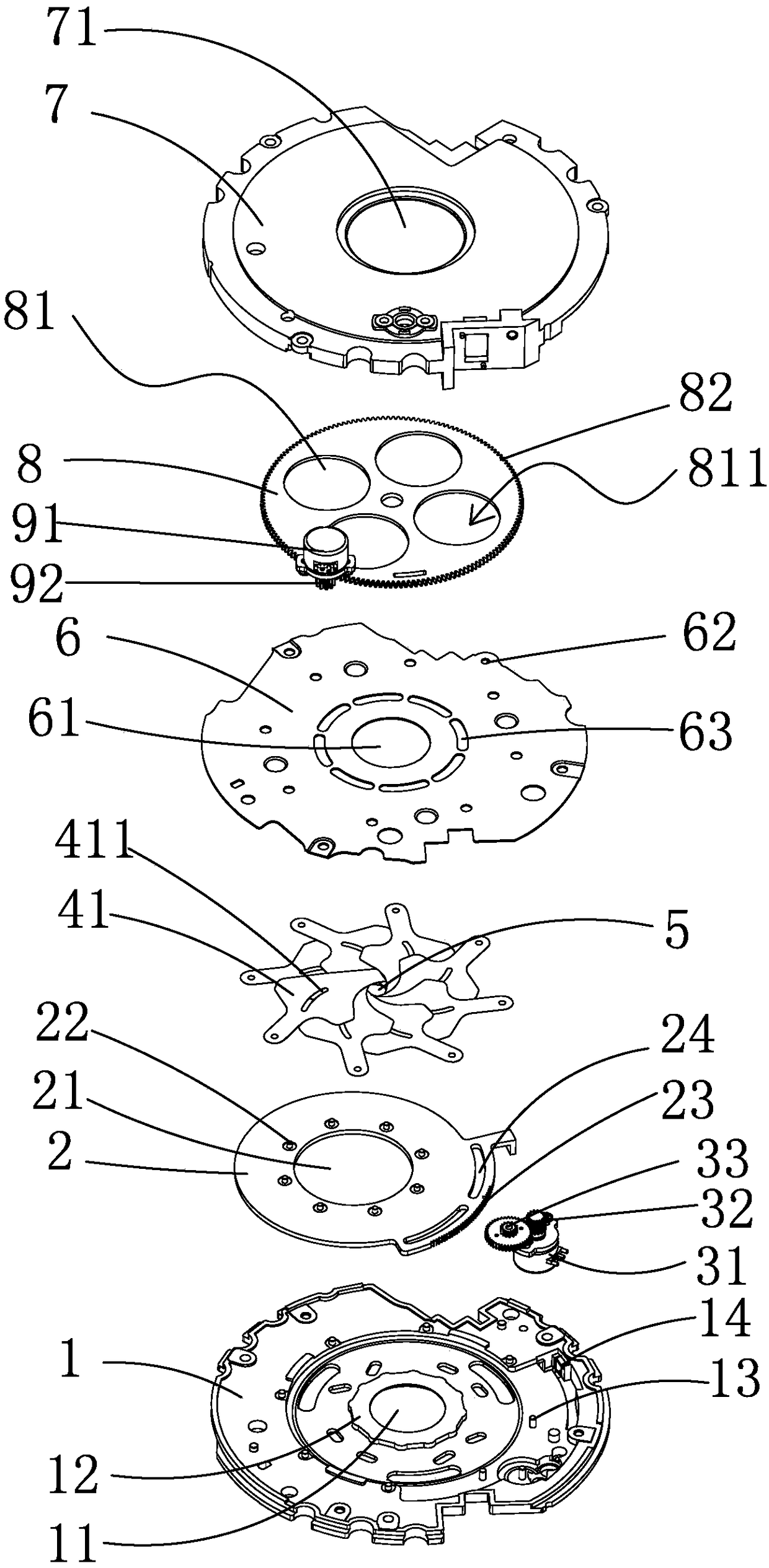

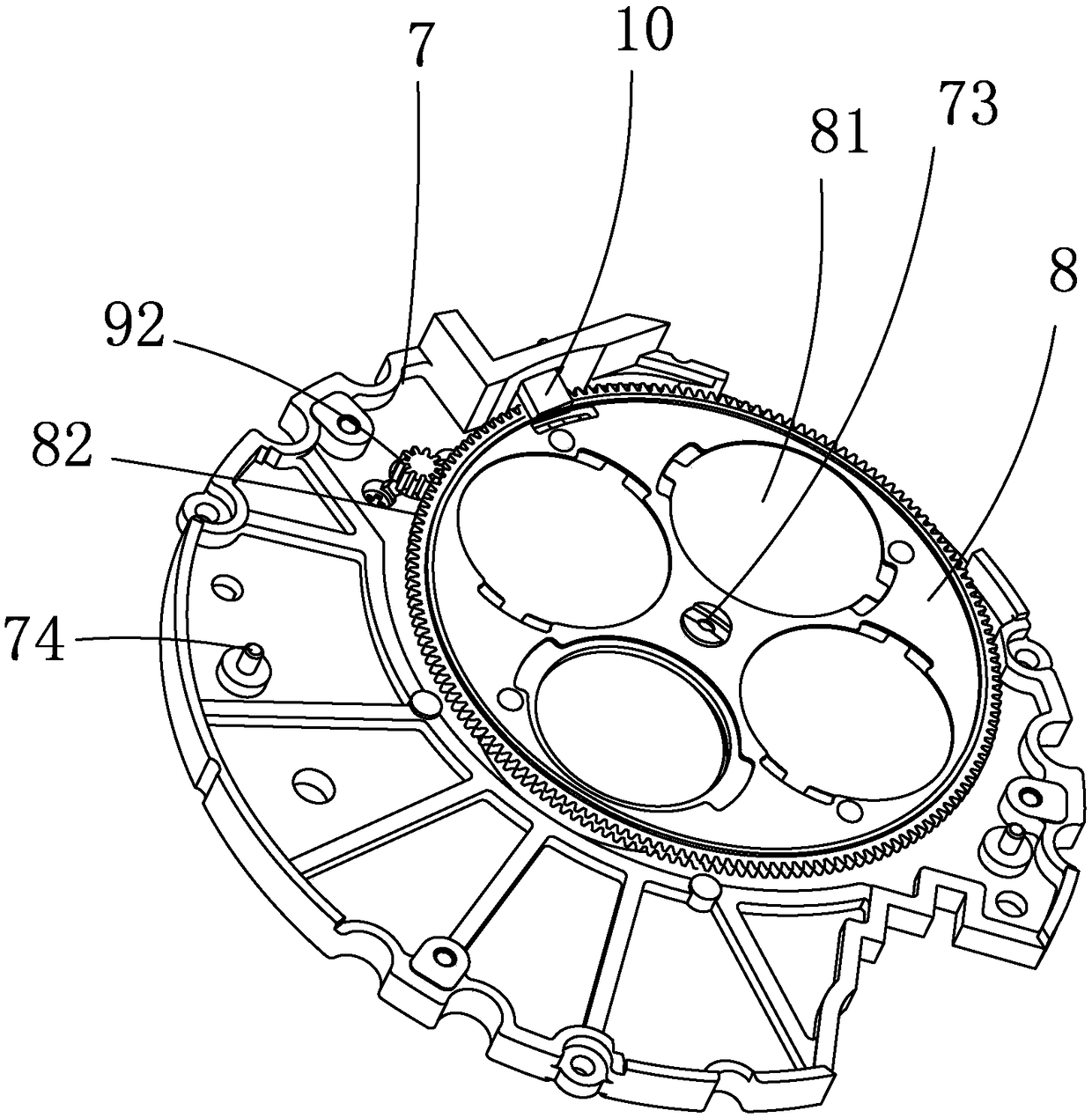

[0028] like Figure 1 to Figure 4 As shown, a step aperture structure with a light reduction film conversion device includes a base 1 and a cover plate 6 arranged on the base 1, the base 1 is provided with a base through hole 11, and the cover plate 6 is provided with There is a cover plate through hole 61 communicating with the base through hole 11, an aperture assembly 4 is provided between the base 1 and the cover plate 6, and a diaphragm assembly 4 is provided between the base 1 and the cover plate 6 to drive the operation of the aperture assembly 4. Then adjust the first drive assembly of the size of the aperture 5; the cover plate 6 is provided with a fixed seat 7, and the fixed seat 7 is provided with a fixed seat through hole 71 communicating with the cover plate throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com