Stepping aperture device with photoelectric detection device

A photoelectric detection and aperture technology, applied in aperture, optics, camera and other directions, can solve the problems of inability of aperture to achieve high-precision control, unfavorable precise adjustment of aperture size, low transmission accuracy of transmission mechanism, etc., and achieves simple structure and adjustment control. High precision and the effect of increasing the transmission ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

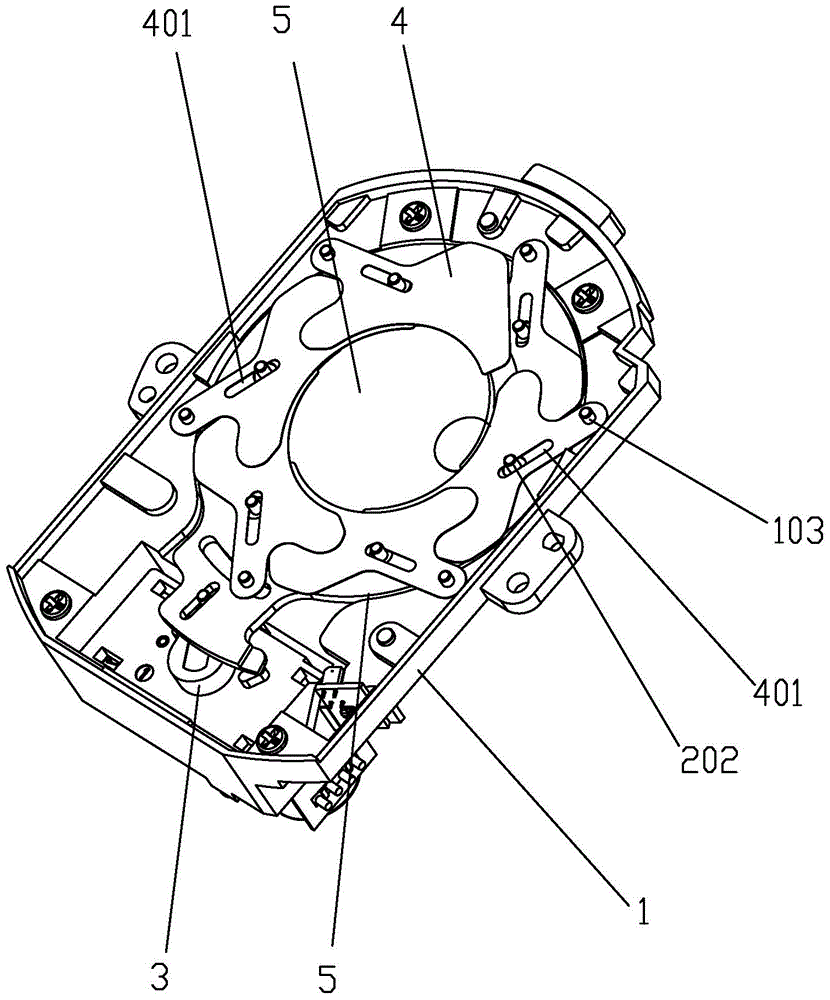

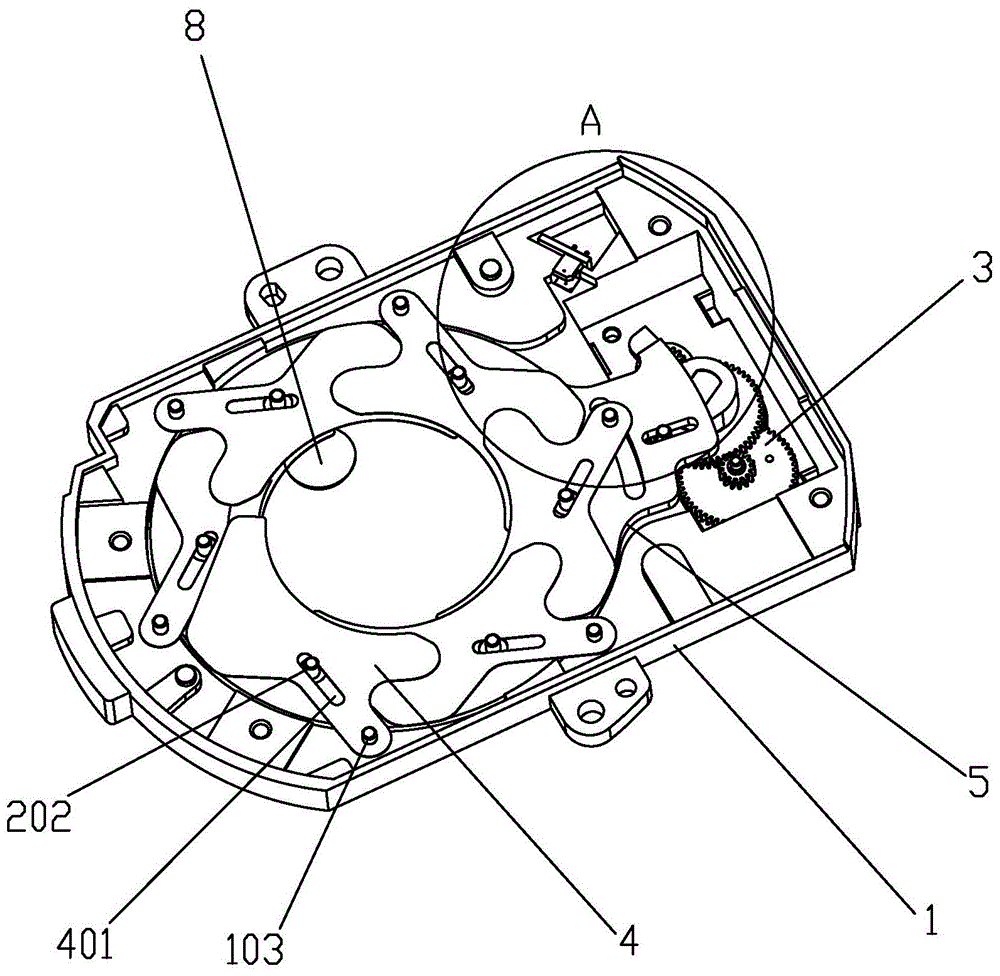

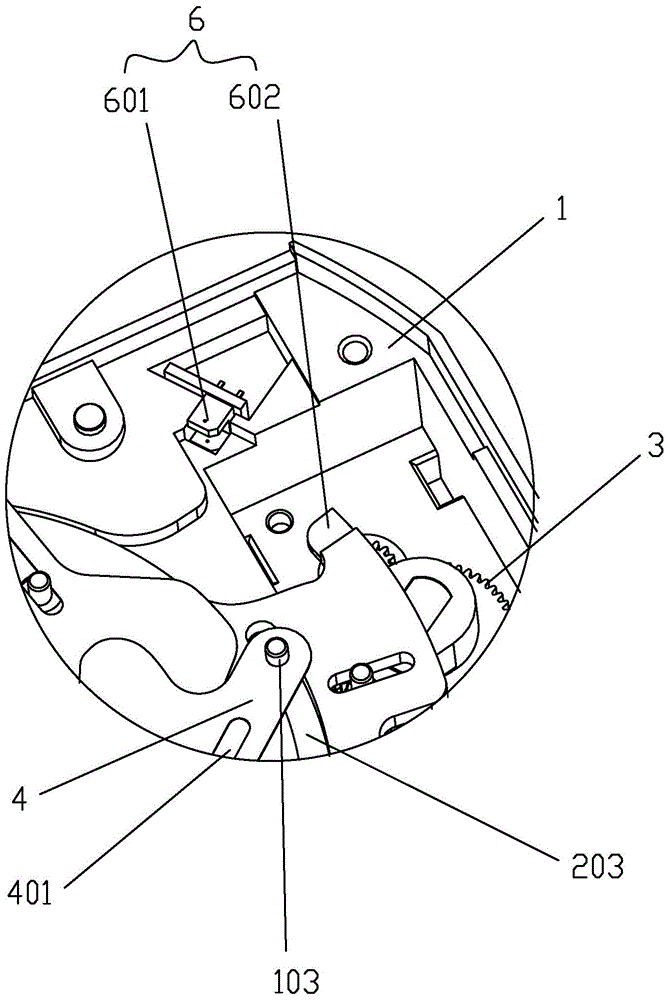

[0027] Such as Figure 1 to Figure 7 As shown, a stepping aperture device with a photoelectric detection device includes a base 1, the base 1 is provided with a base through hole 101 and a boss 102 surrounding the base through hole 101, and the boss 102 is sleeved There is a turntable 2, the turntable 2 is provided with a turntable through hole 201 communicating with the base through hole 101, the base 1 is provided with a drive device 3 for driving the turntable 2 to rotate, and the base 1 is located on the boss The periphery of 102 is provided with a plurality of protruding columns 103 distributed in a circular array, and the turntable 2 is provided with a plurality of dials 202 distributed in a circular array, and each of the protruding columns 202 is provided with a blade 4 that can rotate around it. The blade 4 is provided with a strip-shaped hole 401 for the dial 202...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com