Novel fork clamping machine

A technology of gripping machine and fork, which is applied in the direction of lifting device, etc., can solve problems such as affecting the quality of internal goods and insufficient fork gripping machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

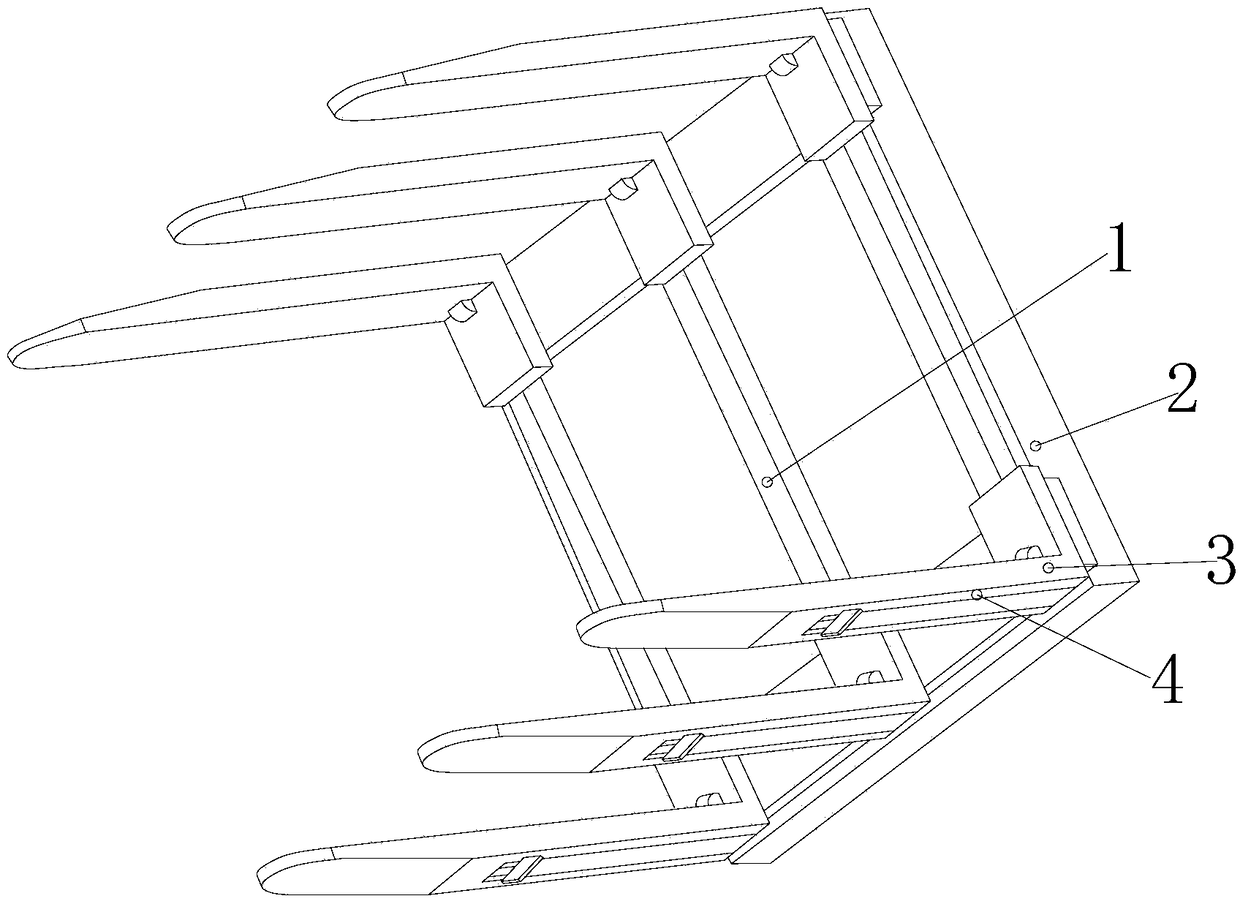

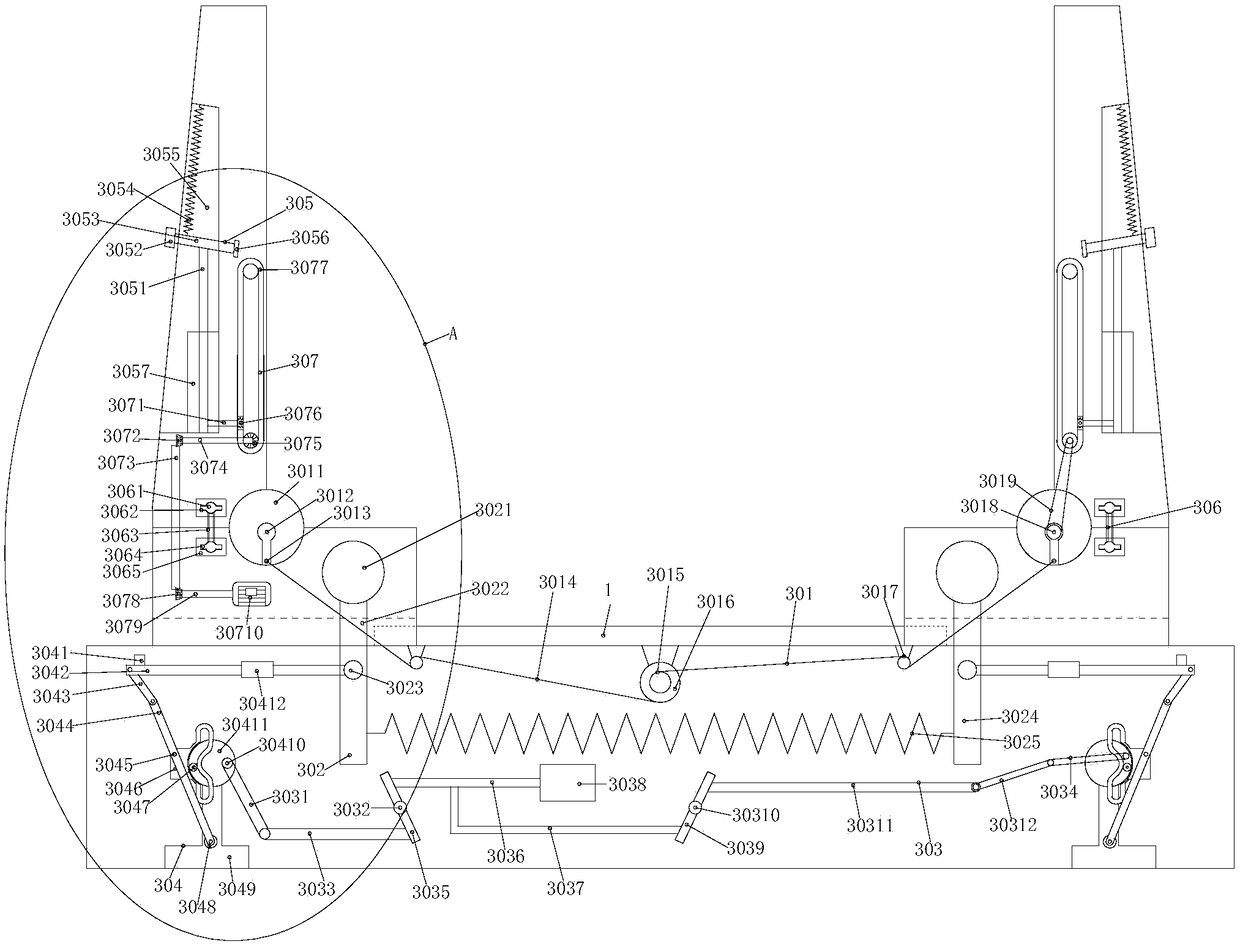

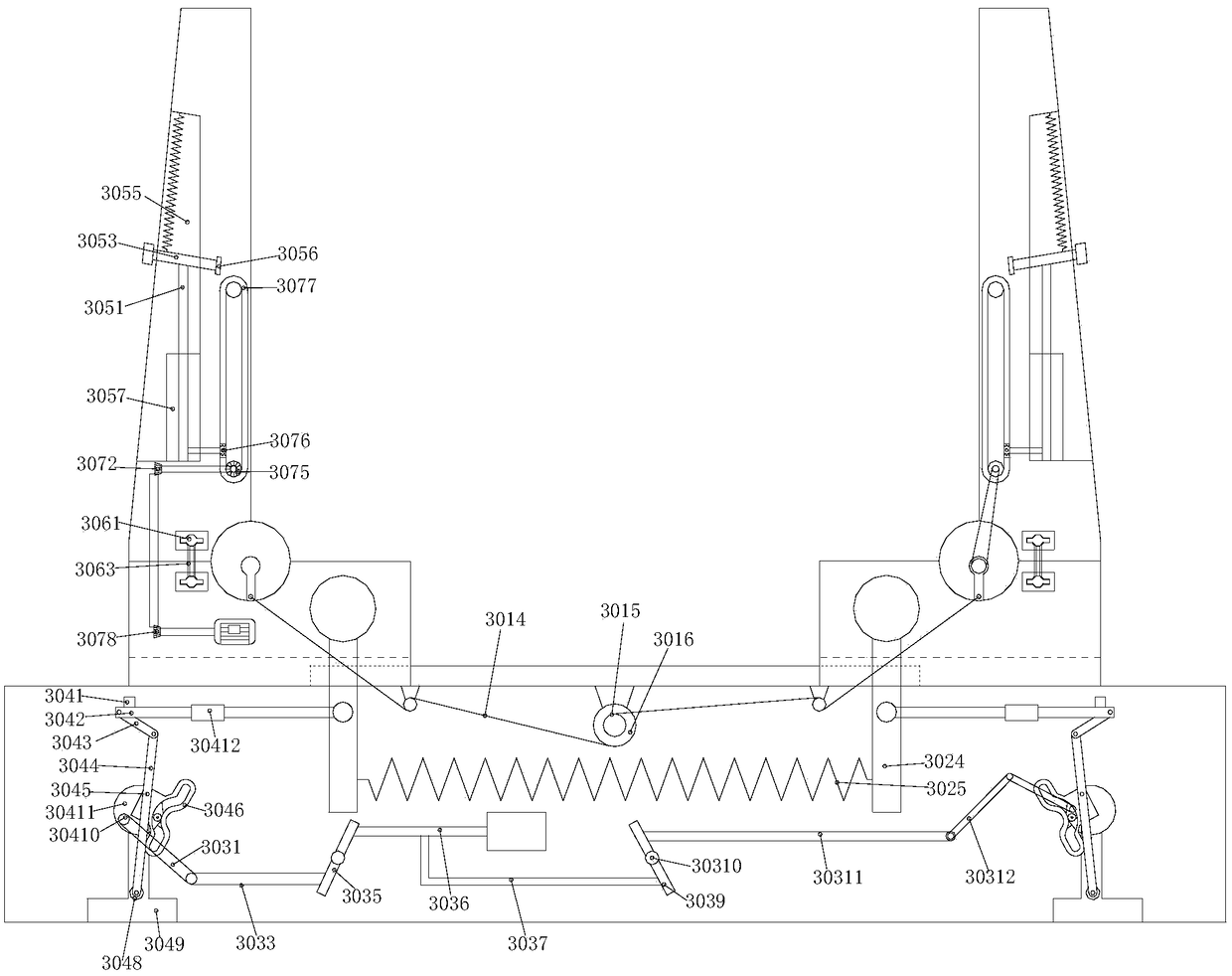

[0025] see Figure 1-Figure 5 , the present invention provides a new type of fork clamping machine, the structure of which includes a raised rail 1, a fixed seat 2, a clamping device 3, and a clamping arm 4. The raised rail 1 is provided with three and two parallel to each other. On the fixing base 2, the fixing base 2 is mechanically connected with the clamping device 3, and the clamping arm 4 is mechanically matched with the clamping device 3;

[0026] The clamping device 3 is composed of a transmission mechanism 301, a sliding elastic mechanism 302, a driving mechanism 303, a push-pull device 304, a sliding mechanism 305, a fixed stretching mechanism 306, and a mechanical driving device 307;

[0027] The transmission mechanism 301 is mechanically cooperated with the clamping arm 4, the sliding elastic mechanism 302 is mechanically connected with the clamping arm 4, the sliding elastic mechanism 302 is mechanically cooperated with the push-pull device 304, and the described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com