On-water operation support device and method

A supporting device and operation technology, applied in water conservancy projects, underwater structures, artificial islands, etc., can solve the problems of poor wind and wave resistance, inconvenient movement, long construction period, etc., and achieve strong wind and wave resistance, installation and disassembly. The effect of convenience and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

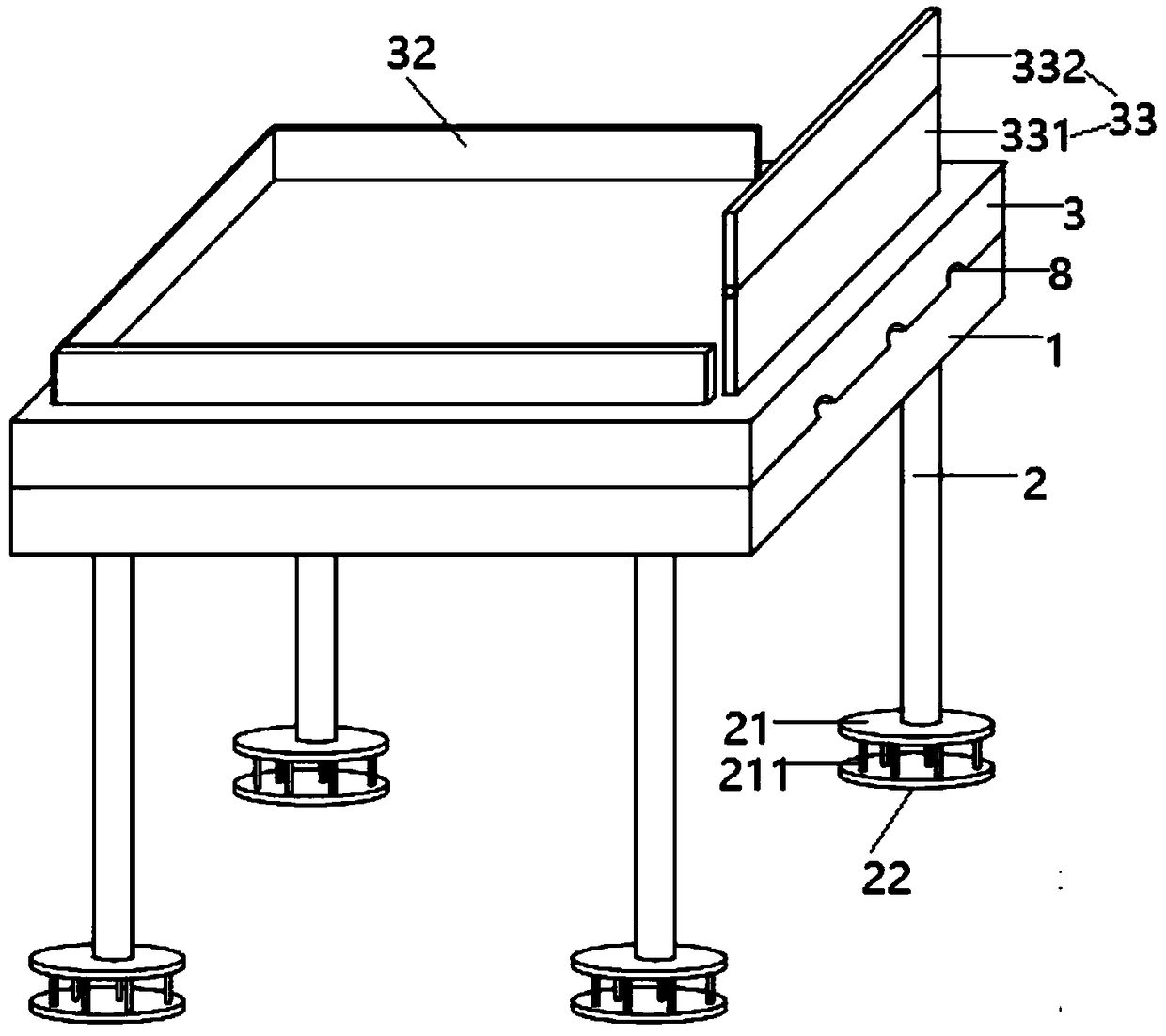

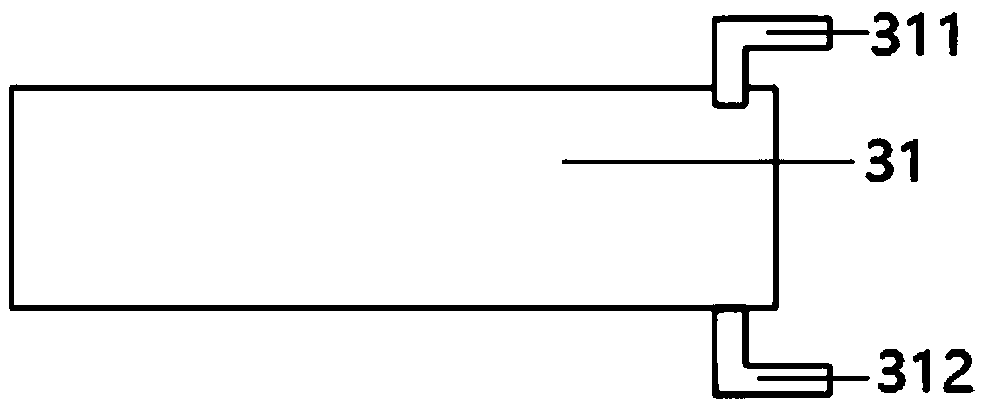

[0048] Such as figure 1 , figure 2 , Figure 5The shown embodiment is a support device for water work, including a support frame 1, four support piles 2 arranged at the lower part of the support frame, and a work platform 3 arranged on the support frame; a ballast water tank 31 is provided in the work platform, A water inlet pipe 311 and an outlet pipe 312 are arranged on the ballast water tank, a water pump 35 and a vacuum pump 36 are arranged on the water inlet pipe, a solenoid valve 3011 is arranged on the water inlet pipe and the water outlet pipe, and a pressing plate 21 is arranged at the lower end of each supporting pile. The lower surface is provided with 6 columns 211, and each column is provided with permanent magnets 2111, and the lower part of the ground at the bottom of the water is provided with 4 connecting plates 22 corresponding to the positions of each pressing plate, and each connecting plate is provided with 6 Each positioning pin 221 is respectively use...

Embodiment 2

[0064] Embodiment 2 comprises all structures and method parts in embodiment 1, as figure 1 As shown, the work platform of embodiment 2 is also provided with a windshield 33, the windshield includes a lower rectangular plate 331 and an upper rectangular plate 332, the lower rectangular plate and the upper rectangular plate are connected by a rotating shaft, and the rotating shaft is provided with a Drive the rotating motor 334 that the upper rectangular plate rotates along the lower rectangular plate, as Figure 5 As shown, the rotating motor is electrically connected to the controller.

[0065] (8-1) The operator obtains the current wind speed data information through the network, and the wind speed threshold is set to K; K is 10 m / s;

[0066] (8-2) When the wind speed > K, the operator controls the rotation motor to work through the controller, so that the angle between the upper rectangular plate and the lower rectangular plate is 180°, and the upper rectangular plate and t...

Embodiment 3

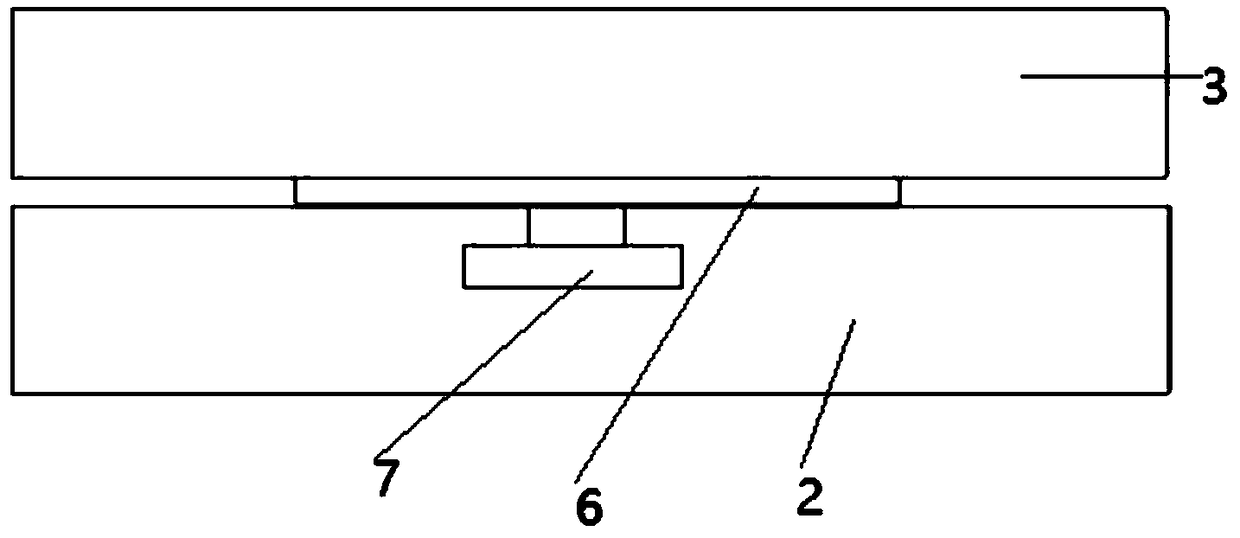

[0070] Embodiment 3 comprises all structures and method parts of embodiment 2, as image 3 , Figure 5 As shown, the working platform of embodiment 3 is provided with wind direction anemometer 5, and the upper surface of support frame is provided with turntable 6, and turntable is connected with work platform, and support frame is provided with turntable motor 7, and work platform lower surface is provided with 3 Parallel diversion grooves 8, the windshields are perpendicular to each diversion groove, and the wind direction anemometer and the turntable motor are all electrically connected to the controller.

[0071] Steps (8-1) to (8-3) are replaced by the following steps:

[0072] (9-1) The wind direction anemometer detects the current wind direction and wind speed, and the wind speed threshold is set to K;

[0073] (9-2) When the wind speed > K, the operator controls the rotation motor to work through the controller, so that the angle between the upper rectangular plate an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com