Anti-sinking device for hard corrugated outer tube wall

An outer pipe wall, anti-sag technology, applied in the direction of pipes, rigid pipes, pipe components, etc., can solve the problems of outer pipe wall damage, work troubles, disassembly troubles, etc., to improve production guarantee, avoid disassembly of corrugated pipes, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

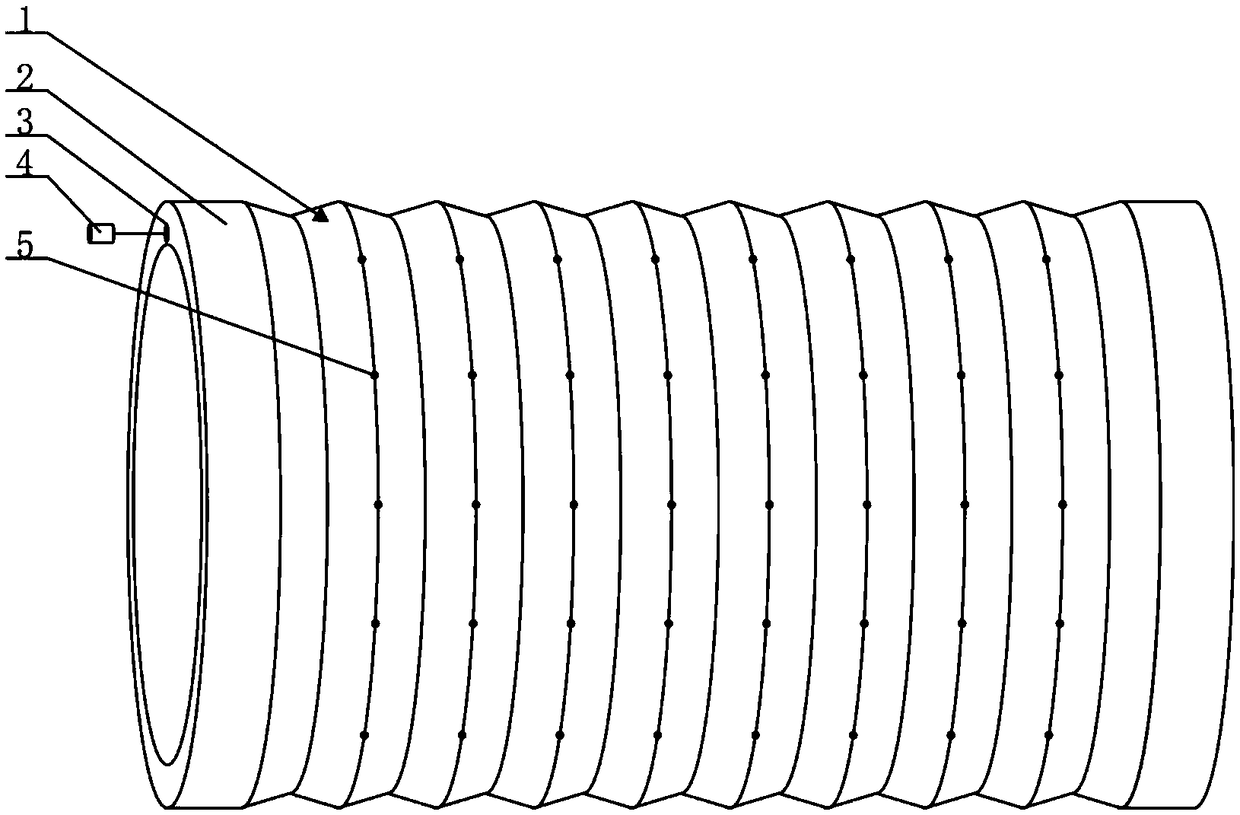

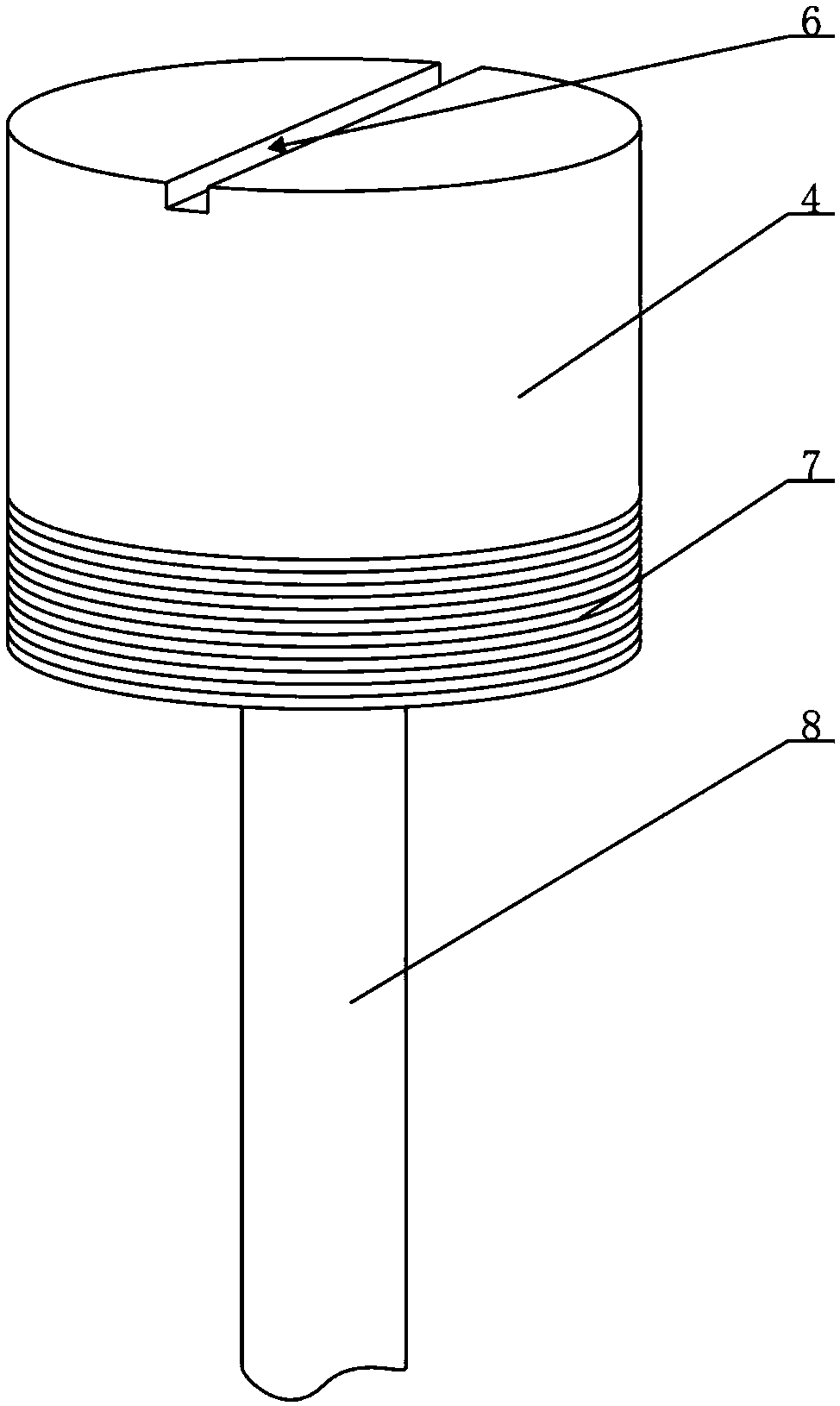

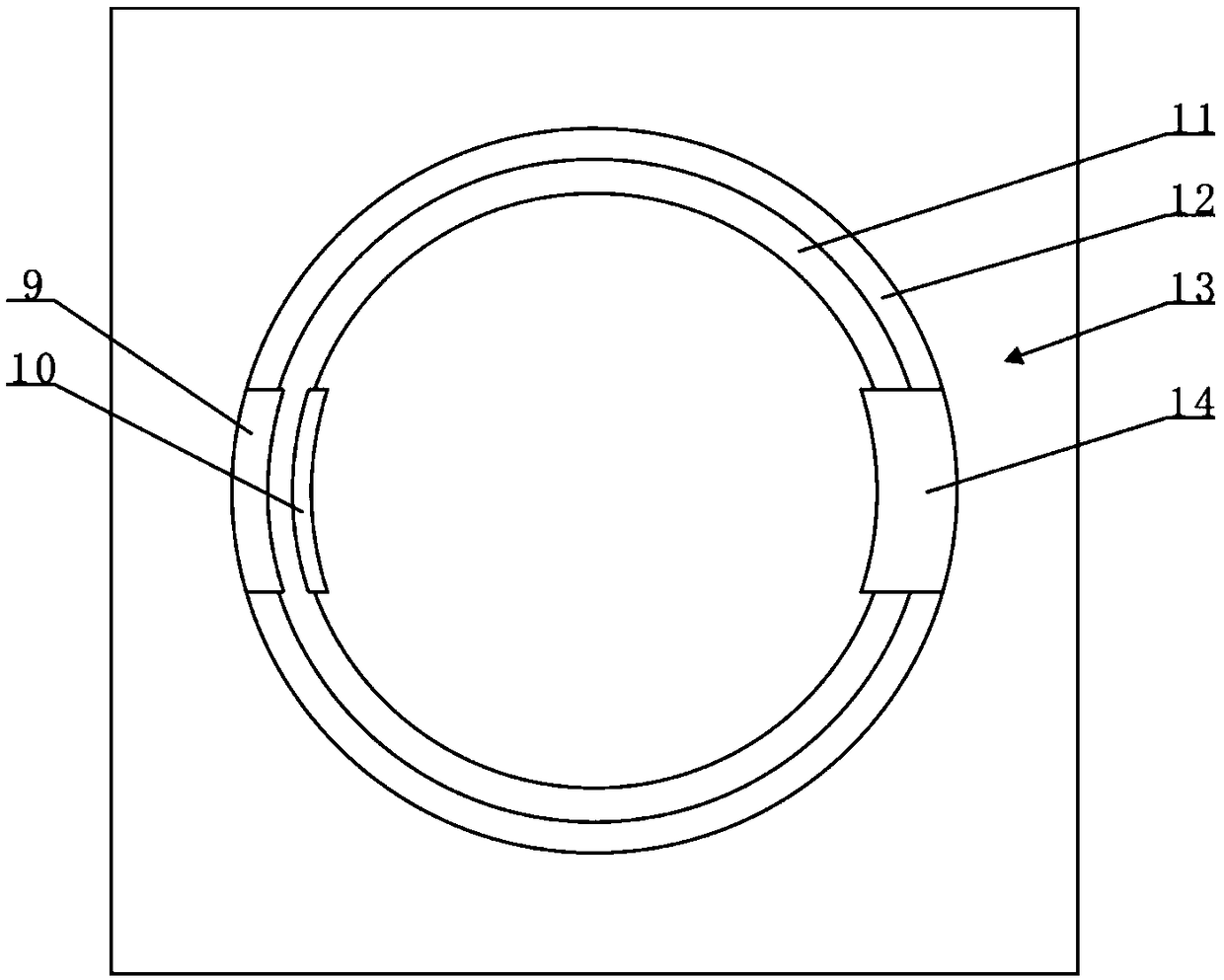

[0032] Example 1, the anti-sag device for the hard corrugated outer tube wall, when in use, when a certain part of the tube body 2 is depressed, first use a screwdriver to twist the slot 6 on the rod cap 4, The screw thread 7 on the rod cap 4 is pulled out from the clamping hole 3, the rod cap 4 drives the operating rod 8 to rotate, the operating rod 8 is pulled out from the clamping hole 3 on the pipe body 2, and then the chassis 13 is placed on the pipe body 2 In the recessed place, insert the operating rod 8 through the hole in the middle of the chassis 13, and use the operating rod 8 at the lower part of the chassis 13 to connect the limit ring 5 around the outer recess of the pipe body 2. The limit ring 5 is at least Three, use the operating rod 8 to put the limit ring 5 together, and then pull the block 10 on the buckle 11, so that the block 10 pops out from the lower part of the limit block 9 on the inner rail 12, and continue to push the buckle 11 upward Pull, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com