Mechanical air-gas linkage valve

A wind-air linkage valve, mechanical technology, applied in the direction of mechanical equipment, valve details, multi-way valves, etc., can solve the problems of inconvenient use, difficult to control accurately, and large temperature influence, and achieve the effect of easy use and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

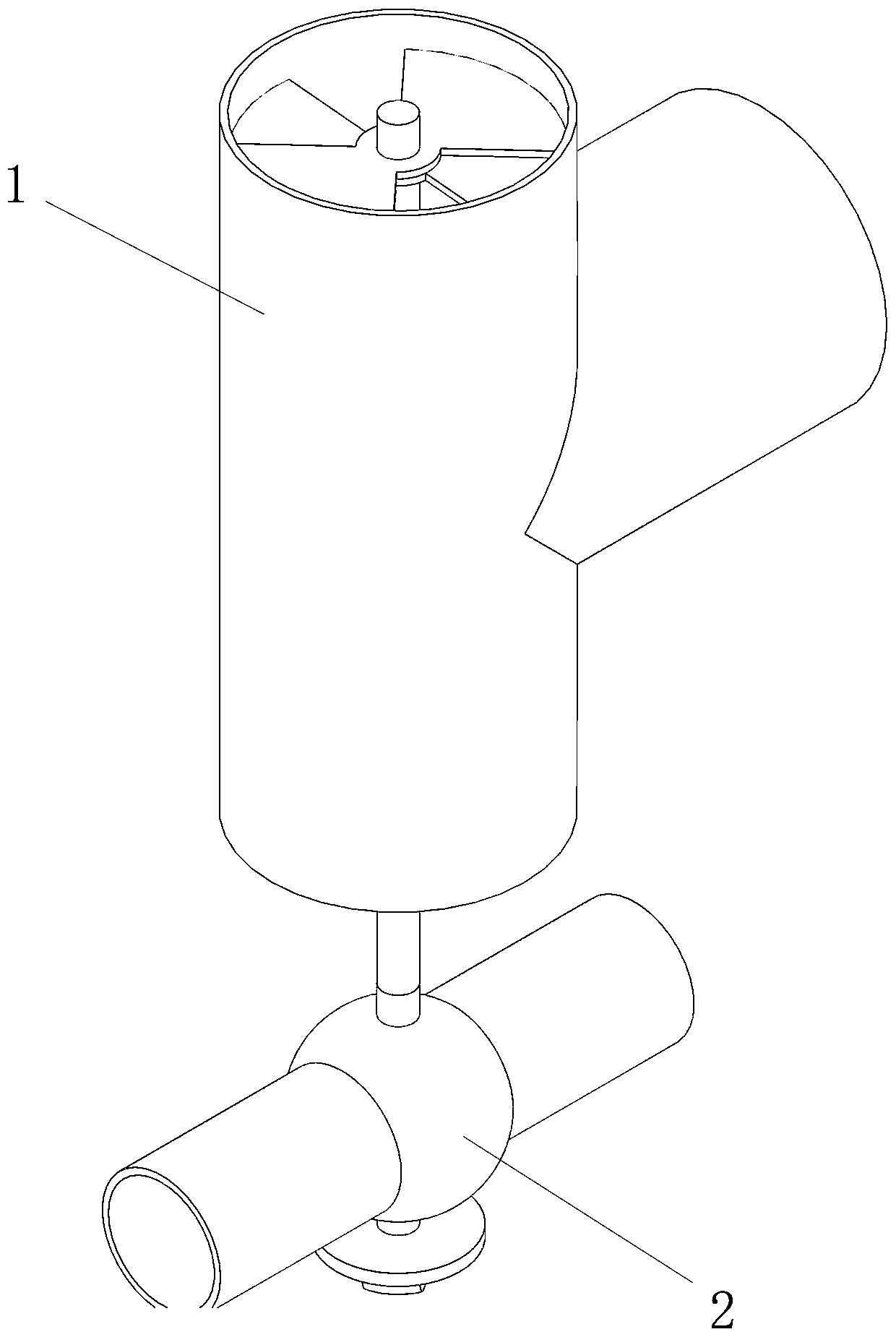

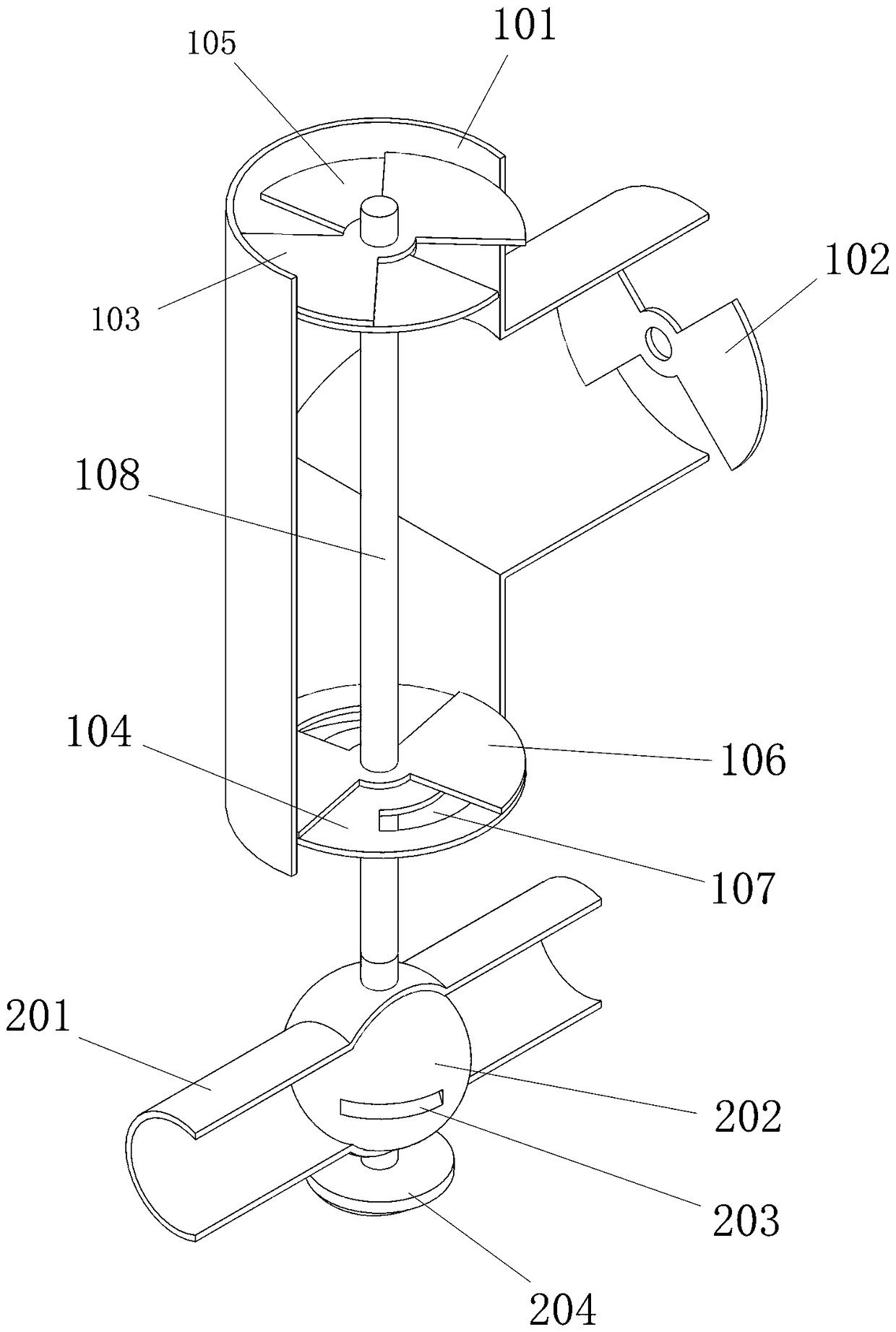

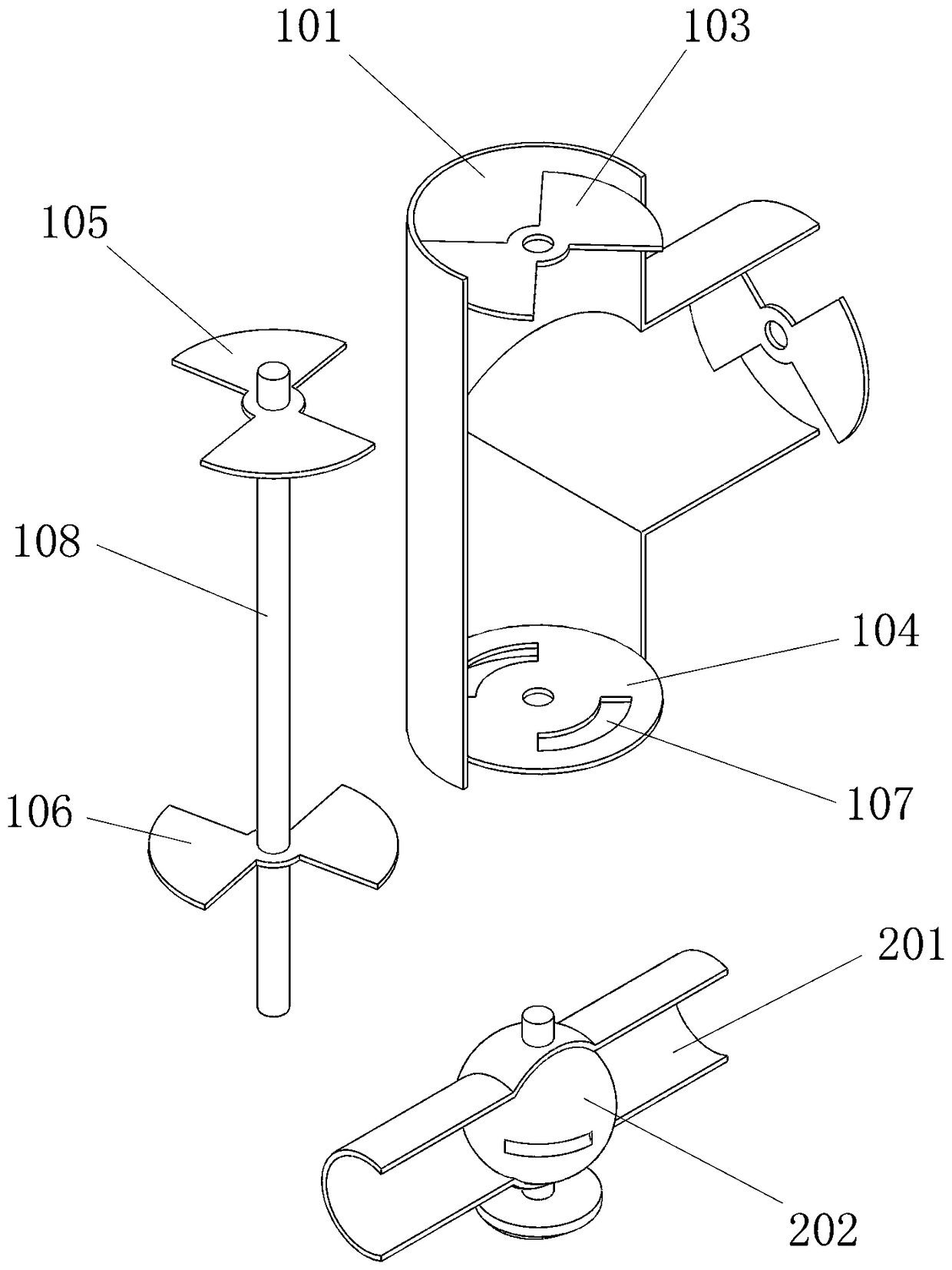

[0026] Such as Figure 1-3 As shown, a mechanical air-air linkage valve includes a relatively fixed T-shaped valve 1 and a ball valve 2. The T-shaped valve 1 includes a T-shaped housing 101 and a general gas-assisting valve 102 arranged in the T-shaped housing 101. , the first fixed valve plate 103, the second fixed valve plate 104, the first moving valve plate 105, the second moving valve plate 106 and the linkage shaft 108, the first fixed valve plate 103, the first moving valve plate 105, the first The two moving valve plates 106 are all butterfly-shaped, and the second moving valve plate 106 is provided with an arc-shaped through hole 107, and the first fixed valve plate 103 and the second fixed valve plate 104 are respectively arranged on the T-shaped housing 101. At both ends of the direct connection, the main gas-assisting valve 102 is set at the other end, and the first moving valve piece 105 and the second moving valve piece 106 are respectively in close contact with ...

Embodiment 2

[0030] Such as Figure 5-7 As shown, the difference from Embodiment 1 is that this embodiment also includes a first manual adjustment valve plate 301 and a second manual adjustment valve plate 302, which are respectively located on the first fixed valve plate 103 and the second fixed valve plate The side of 104 away from the first movable valve plate 105 and the second movable valve plate 106 is butterfly-shaped and is provided with a paddle 303 protruding from the T-shaped housing 101, and the T-shaped housing is provided with a paddle 303 moving guide seam 304 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap