Alkali-resistant anion-exchange membrane loaded with substituted imidazole units and preparation method thereof

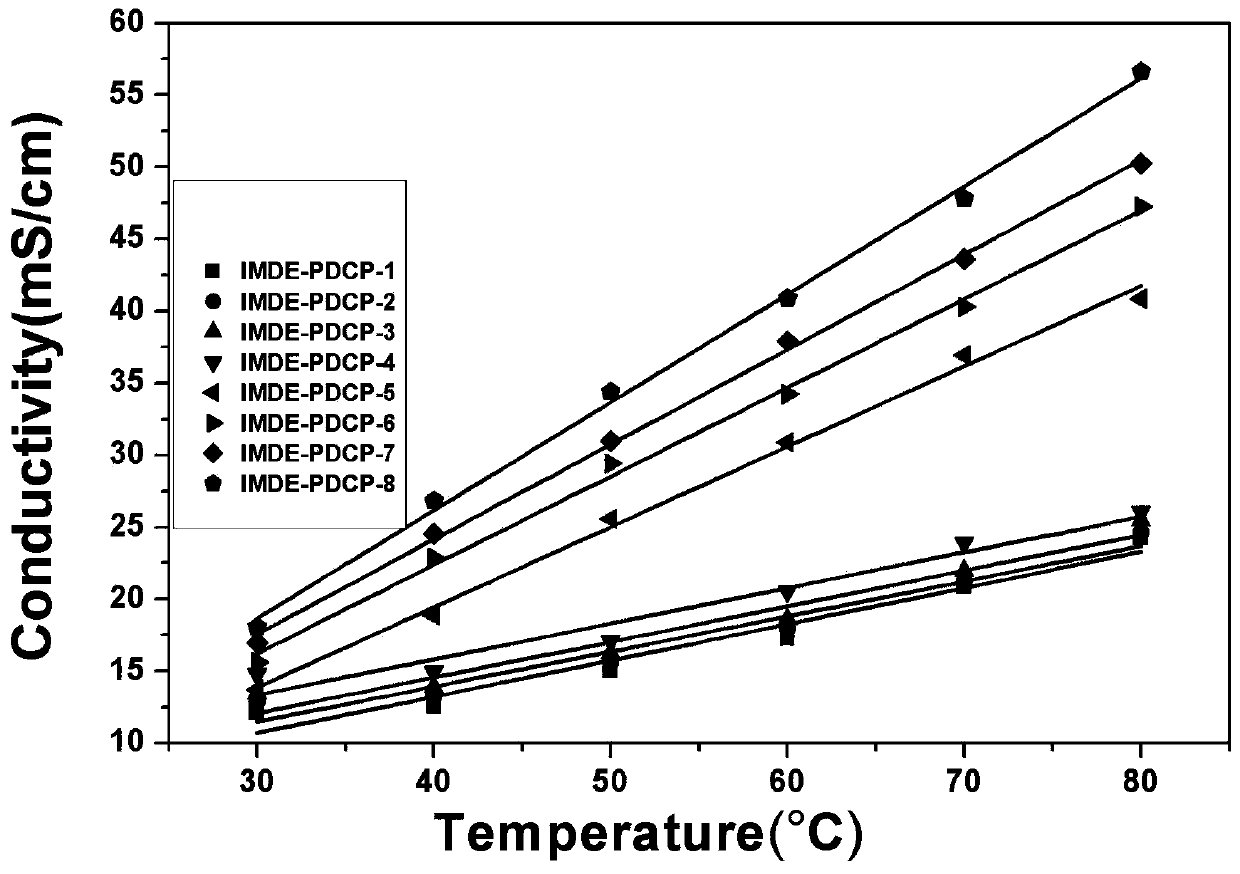

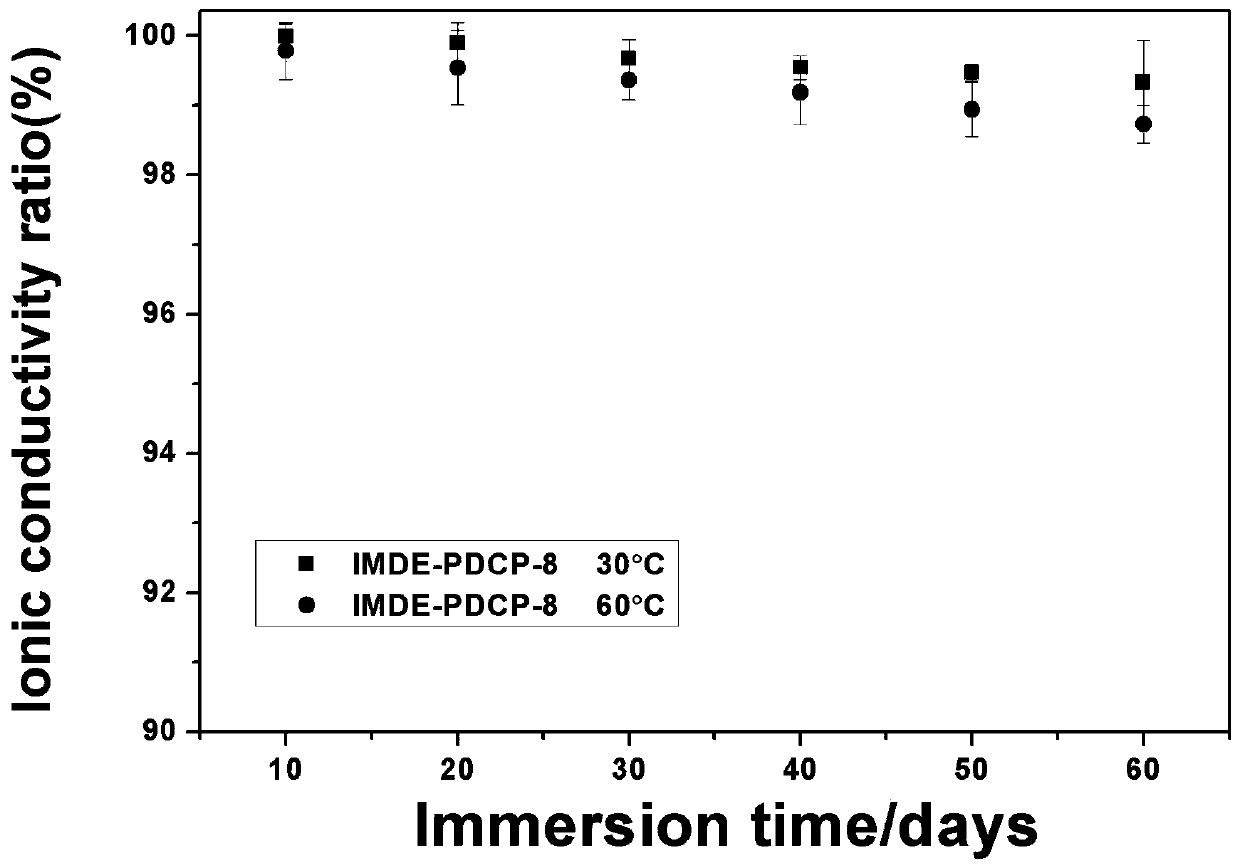

An anion-exchange membrane and alkali-resistant technology, which is applied in electrical components, fuel cells, electrochemical generators, etc., can solve the problems of no imidazole unit load, synthesis of anion-exchange membrane without imidazole unit load, etc., and achieve excellent alkali stability The effect of high conductivity and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

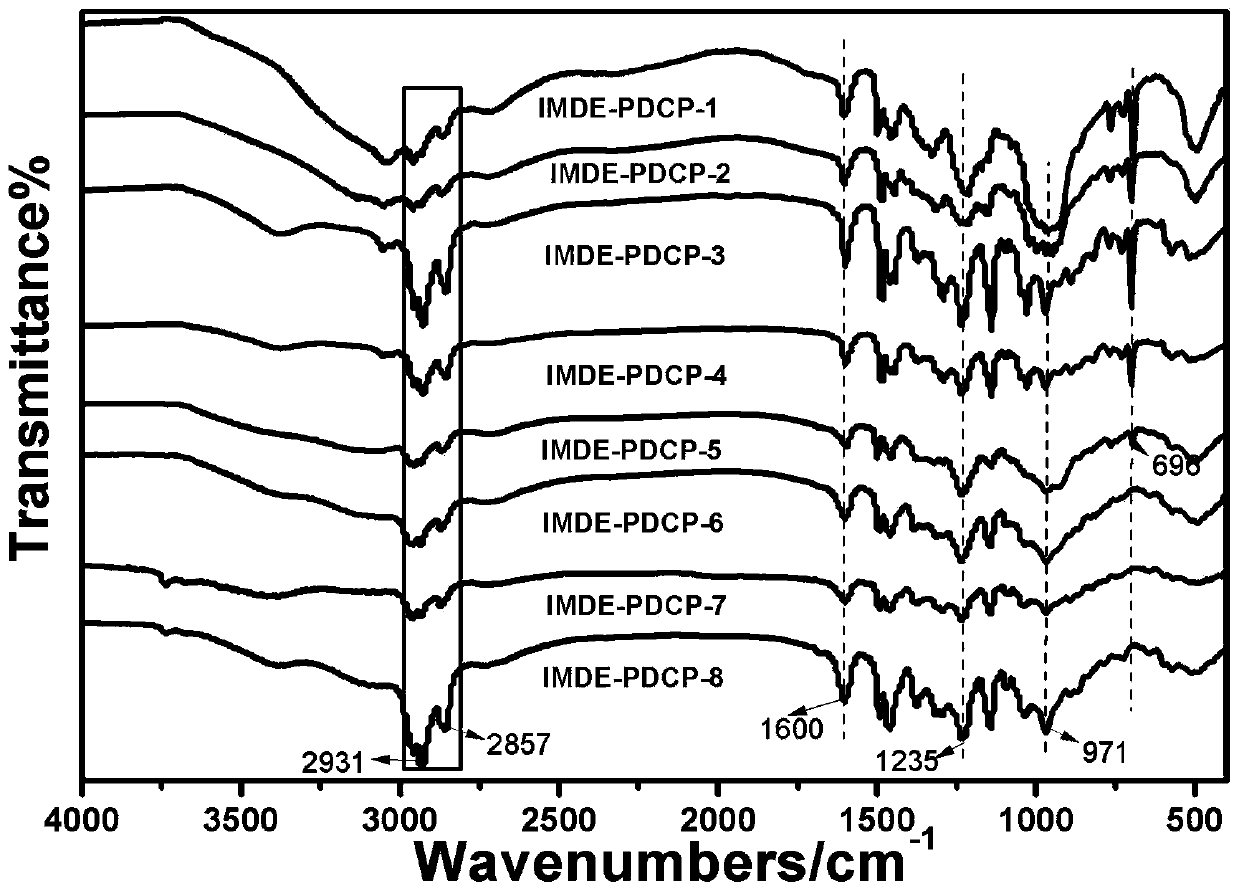

Method used

Image

Examples

Embodiment 1

[0035] (1) Add benzil 6.3g (30mmol), 2,6-dimethyl-4-hydroxybenzaldehyde 4.5g (30mmol), aniline 2.8g (30mmol), ammonium acetate 2.3g (30mmol) in a three-necked flask ), L-proline 0.5g, 160mL methanol, heated to reflux at 70°C for 24 hours under a nitrogen atmosphere (after adding the drug, nitrogen was purged for 10 minutes, then a balloon was installed to stop the nitrogen, and the system was kept in a closed environment). After the reaction, white crystals were precipitated, and the product of formula (2) was obtained by suction filtration under reduced pressure. Get 6g as (R in formula (2) 1 = phenyl, R 2 = phenyl, R 3 =butyl) imidazole and 1.2eq of NaOH were placed in DMF solvent, reacted at room temperature for 24h, and then distilled under reduced pressure to obtain imidazole sodium salt;

[0036] (2) Add the above-mentioned imidazole phenol sodium salt into a THF solution containing 2.8 g of polydichlorophosphazene (imidazole substitution ratio is 40%), and react at 6...

Embodiment 2

[0042](1) In a three-necked flask, add benzil 6.3g (30mmol), 2,6-dimethyl-4-hydroxybenzaldehyde 4.5g (30mmol), ethanol solution 4.7g (30mmol), ammonium acetate 2.3 g (30mmol), L-proline 0.5g, anhydrous Na 2 SO 4 4g, 200mL of methanol, heated at 80°C for 24h under nitrogen atmosphere, cooled to room temperature, and crystals were precipitated, which was the product of formula (2). Get 5.52g as (R in formula (2) 1 = phenyl, R 2 = ethyl, R 3 =butyl) imidazole and 1.2eq of NaOH were placed in DMF solvent, reacted at room temperature for 24h, and then distilled under reduced pressure to obtain imidazole sodium salt;

[0043] (2) Add the above-mentioned imidazole phenol sodium salt into a THF solution containing 2.8 g of polydichlorophosphazene (imidazole substitution ratio is 40%), and react at 60°C for 48 hours;

[0044] (3) Add 1.58g of unsubstituted n-pentyl alcohol and 1.2eq of sodium metal into THF, and react at room temperature for 4h to obtain a suspension of sodium n-...

Embodiment 3

[0049] (1) In a three-necked flask, add benzil 6.3g (30mmol), 2,6-dimethyl-4-hydroxybenzaldehyde 4.5g (30mmol), butylamine 2.2g (30mmol), ammonium acetate 2.3g ( 3mmol), L-proline 0.5g, anhydrous Na 2 SO 4 4g, 200mL methanol, heated and stirred at 80°C under nitrogen atmosphere for 24h to obtain a dark brown liquid. Cool to room temperature without solid precipitation, place in the refrigerator to freeze, and the precipitated solid is the product of formula (2). Get 5.8g as (R in formula (2) 1 = phenyl, R 2 = butyl, R 3 =butyl) imidazole and 1.2eq of NaOH were placed in DMF solvent, reacted at room temperature for 24h, and then distilled under reduced pressure to obtain imidazole sodium salt;

[0050] (2) Add the above-mentioned imidazole phenol sodium salt into a THF solution containing 2.8 g of polydichlorophosphazene (imidazole substitution ratio is 40%), and react at 60°C for 48 hours;

[0051] (3) Add 1.58g of unsubstituted n-pentyl alcohol and 1.2eq of sodium meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com